Heavy industrial doors, panels, and enclosures depend on hinges for safe, reliable motion and long-term performance.

The load capacity of industrial hinges depends on key design elements like leaf size, pin diameter, material strength, number of hinges, mounting method, and usage conditions.

Explore these factors to ensure your hinges are built to handle the weight and duty cycle of your equipment.

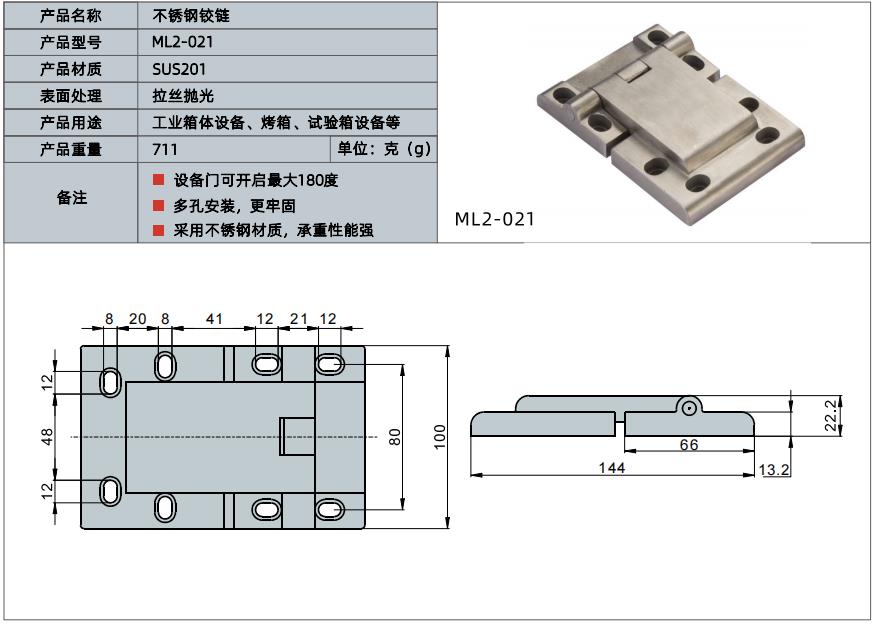

Hinge Leaf Size and Thickness

A hinge’s leaf is the flat plate that is fastened to a door or panel. The size and thickness of these leafs directly impact the hinge’s ability to bear weight.

Wider and thicker hinge leaves distribute weight more effectively, minimizing stress and increasing total load capacity.

Importance of Surface Contact Area

The surface area of the hinge leaf plays a pivotal role in stabilizing the attached door or panel. Larger leaves provide a greater interface between the door and the frame, dispersing the force more evenly. This reduces the chance of deformation or detachment, especially under dynamic loads.

Impact on Stress Distribution

In high-load applications like trailer door hinges or cold storage room hinges, large and thick leaves not only support more weight but also absorb more mechanical stress over time. Engineers often choose longer piano hinges for this reason, as they distribute the load across the entire length of the door.

Pin Diameter and Hinge Knuckle Design

The central pin of a hinge connects the two leaves and forms the rotational axis. Its diameter and strength are critical for heavy-duty usage.

Thicker and stronger pins improve rotational support and structural integrity under load-bearing applications.

Pin Material vs. Diameter Tradeoff

Stronger materials like stainless steel or hardened carbon steel allow for thinner pins that still handle high stress. In contrast, softer metals require thicker pins for the same load rating. For heavy duty hinges, large diameter pins made from treated steel offer durability in high-stress environments.

Knuckle Design for Torsional Load Resistance

The knuckle geometry also matters. A tight-fitting, well-machined knuckle reduces “End Play”—the axial movement of the hinge when load is applied. Minimal end play is essential for doors that must seal tightly, such as climatic test chamber hinges or enclosures exposed to vibration.

Hinge Material Strength and Composition

Material selection affects corrosion resistance, tensile strength, and long-term performance under repeated loading.

Carbon steel and stainless steel offer superior load-bearing capabilities compared to brass or aluminum due to higher tensile strength.

Comparative Load Table by Material

| Material | Tensile Strength (MPa) | Corrosion Resistance | Industrial Use Cases |

|---|---|---|---|

| Carbon Steel | 400–800 | Low | Machine enclosures, weld-on hinges |

| Stainless Steel | 500–900 | High | Marine hinges, cleanroom doors |

| Brass | 200–400 | Moderate | Decorative panels, low-load applications |

| Aluminum | 100–250 | Moderate | Aluminum hinges for lightweight access panels |

Choosing Based on Environment

In marine or corrosive environments, material strength isn’t enough—resistance to rust and chemical exposure is critical. For such use cases, marine hinges made from 316 stainless steel or corrosion-resistant coatings are preferred. In contrast, carbon steel with surface treatment is ideal for dry, indoor settings with high load demands.

Number of Hinges Used

Adding more hinges along the mounting surface increases total load capacity and helps distribute stress evenly.

More hinges increase weight distribution and reduce load per hinge, improving safety and longevity.

2-Hinge vs. 3-Hinge Configurations

Two hinges are standard for smaller or medium-weight doors, but for larger panels—especially over 80 inches tall or 200 pounds—three or more hinges are recommended. The third hinge typically goes in the center to support added torque and vibration resistance.

Mathematical Estimation Models

A rough formula used in industrial applications:

Hinge Capacity = Total Door Weight / Number of Hinges × Safety Factor

For instance, a 300-pound door using three hinges with a safety factor of 1.5 would require each hinge to support at least 150 pounds.

Mounting Method and Fastener Quality

Installation plays a critical role in hinge performance. Even a high-grade hinge can fail if mounted incorrectly.

Incorrect installation or low-quality fasteners can drastically reduce hinge load ratings, regardless of hinge strength.

Surface-Mount vs. Weld-On Hinges

Weld on hinges provide permanent, high-strength connections and are ideal for structural applications. In contrast, surface-mounted butt hinges are easier to install but rely heavily on fastener strength and torque.

Fastener Grade and Torque Requirements

Bolts and screws must match the hinge’s grade and mounting hole design. Over- or under-tightening can cause slippage or metal fatigue. Industrial standards often specify torque ranges to maintain optimal compression without distortion.

Load Direction and Frequency of Use

Real-world performance depends not only on static weight but also on the direction of the force and how often the hinge moves.

Vertical vs. horizontal mounting and repeated movement cycles significantly influence the real-world load capacity of hinges.

Static vs. Dynamic Loads

Static loads are easy to estimate, but dynamic loads (doors being opened and slammed multiple times daily) add fatigue stress. Repeated cycling can reduce hinge lifespan, even if the static load is within spec.

Industrial Fatigue Testing Standards

Industrial hinges undergo fatigue testing simulating thousands of open-close cycles. High-cycle applications, such as special hinges in production lines or cleanroom enclosures, must meet performance benchmarks set by ISO or ANSI standards.

Continuous Hinges and Their Capacity

Continuous hinges, or piano hinges, run the full length of the door and offer unmatched load distribution.

Also called piano hinges, continuous hinges distribute weight evenly along the entire length, making them ideal for heavy doors.

Use Cases in Electrical Enclosures

Piano hinges are ideal for control panels, electrical cabinets, or testing enclosures, especially those requiring frequent access. They eliminate stress points by spreading the load uniformly.

Reinforcement with Backplates

For added strength, backplates or reinforcement brackets can be used along the hinge’s spine. This is crucial in high-impact applications like shipping containers, trailer doors, or large server racks.

Hinge Size Standards and Sizing Rules

Industrial hinge sizing follows international standards that help engineers match hinge specs to operational demands.

Industrial hinge sizing follows standards (e.g., ANSI/BHMA), which help estimate hinge dimensions based on door size and weight.

General Formula for Load Calculation

A typical engineering formula for hinge sizing:

Hinge Size (inches) = (Door Height × Door Weight) / 1000

This varies by material and application. Soft close or cam rise hinges may require different specs due to internal spring mechanisms.

Standard vs. Heavy-Weight Classifications

Heavy-weight hinges are built to higher tolerances, with thicker knuckles and hardened pins. These are essential for applications involving constant pressure, vibration, or misalignment over time.

Environmental and Corrosion Considerations

Operating conditions like humidity, temperature, and chemical exposure can affect hinge performance and lifespan.

In humid, outdoor, or chemical environments, material selection and coatings impact long-term load performance.

Stainless Steel for Salt Air

For marine or coastal operations, 316 stainless steel is the material of choice. It resists rust and pitting, even in salt air or chemical vapors.

Zinc Plating vs. Powder Coating

Zinc plating is cost-effective for light protection, while powder coating adds an extra barrier against abrasion and corrosion. Each finish type affects the hinge’s long-term load integrity differently.

Application Type: Static vs. Mobile Equipment

Some applications involve stationary loads, while others deal with movement, vibration, and shifting loads.

Stationary enclosures require different hinge specs than mobile or vibration-exposed machinery.

Truck Doors vs. Test Chambers

Trailer doors need robust, detachable hinges with vibration tolerance and quick maintenance capability. On the other hand, climatic test chamber hinges must support airtight sealing and thermal cycling without deforming or leaking.

Shock Absorption Features in Hinges

Mobile applications benefit from features like built-in dampers or flexible mounting structures that absorb shock loads. Choosing the wrong hinge can lead to structural failure or repeated misalignment.

Conclusion

Selecting the right industrial hinge requires balancing size, material, installation method, and environmental needs to ensure safety and performance in high-load applications.