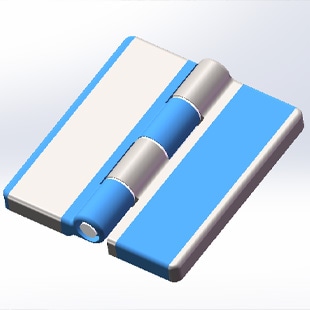

Specialized in Marine Hinges for Ships and Yachts

Marine hinge is a hinge series specially developed by IHINGES for marine and yacht customers.

If you are a retailer or volume buyer. We can offer a wide range of hinges in various sizes. Or if you are a designer or contractor, we offer a professional customized service.

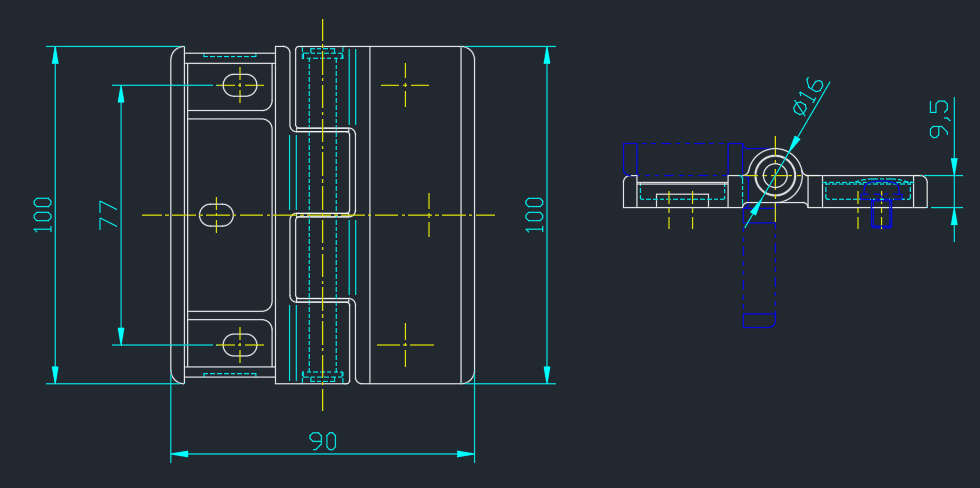

Marine Hinge Specifications

As a leading manufacturer of marine hinges in China. We have the most complete sizes and specifications of marine hinges. We have at least about 1000 regular products in stock.

If you need customized marine hinges, we can make sure to make samples in 20~25 days. The factory has a complete production process and the products are ex-factory price with fast delivery time.

- Fast Delivery

- Customizable

- Quality guaranteed

Why Choose Marine Hinges?

Corrosion Resistance:

Marine hinges are specially crafted to resist rusting, especially in saltwater environments. This ensures that they don't degrade quickly, preserving both function and appearance over time.

Durability:

These hinges are constructed from high-quality materials to withstand harsh marine conditions. As a result, they promise a longer operational lifespan compared to standard hinges.

Low Maintenance:

Due to their inherent resistance to wear and tear, marine hinges require fewer repairs and replacements. This results in cost savings and less downtime for maintenance.

Aesthetically Pleasing:

Often crafted from polished stainless steel or other premium materials, marine hinges provide a sophisticated look. Their sleek appearance aligns well with various boat designs, enhancing overall aesthetics.

Improved Functionality:

Marine hinges are designed with the challenges of the marine environment in mind. They ensure consistent and smooth operation, even when exposed to constant moisture.

Enhanced Safety:

Marine hinges are typically built with locking or secure fastening features. This ensures that doors, hatches, or compartments remain securely closed, preventing potential accidents or losses at sea.

Why marine hinges must be made of 316

Stainless steel 316 contains molybdenum, a key element that greatly enhances its corrosion resistance, especially when exposed to the chloride-rich conditions found in saltwater. Compared to other stainless steel grades, 316 is less susceptible to pitting and crevice corrosion, making it the preferred choice for marine applications. Thus, when manufacturing marine hinges, utilizing 316 ensures that the hardware remains durable, functional, and free from corrosive damage for an extended period, even in the harshest of marine conditions.

REQUEST A QUOTE FOR MORE DETAILS

Installation and Maintenance

Safe structural design:

Marine hinges are used in environments where they can shake violently. Why avoid hurting people during the shaking process, we need to make a sleek design for the structure of the hinge. So that even when you accidentally touch these marine hardware, you will not be injured seriously.

In fact, the last process of producing marine hinges is to make the surface polished. So that the surface does not have any sharp bumps. This makes the hinges aesthetically pleasing and safe.

Mirror Polished Finish:

Mirror polishing is a finishing process designed to produce a smooth and highly reflective surface on stainless steel castings. The process typically involves the following steps:

1. Rough Grinding: The casting is initially ground using coarse abrasives to remove major imperfections and prepare the surface for subsequent steps.

2. Fine Grinding: The surface is further refined with finer abrasives, eliminating minor defects and scratches from the rough grinding phase.

3. Buffing: A soft cloth wheel, usually combined with a fine abrasive compound, is used to buff the surface. This step smooths out any remaining imperfections and begins to produce a reflective shine.

4. Polishing: The casting is polished using extremely fine polishing compounds to achieve a mirror-like finish. Multiple polishing stages may be needed, each using a finer abrasive than the last, to attain the desired glossiness.

5. Cleaning: Post-polishing, the casting is cleaned to remove any residual polishing compounds or debris, ensuring a pristine and highly reflective surface.

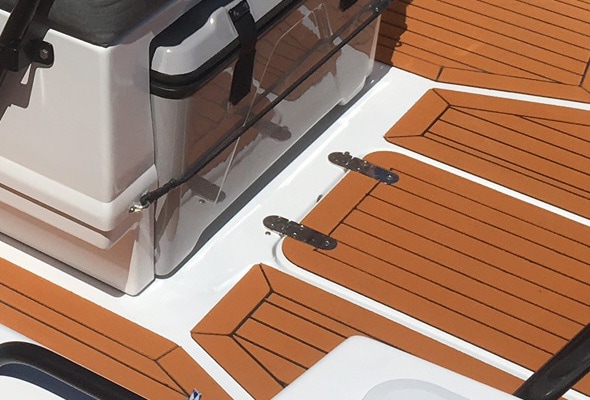

Flush Mounting:

Recessed installation of marine hinges creates a complete flat surface for the deck. The purpose of this is obvious. We can move around the deck without bumping into this marine hardware. Sometimes we need a flat operator’s station to do some work, and that’s when the deck becomes a preferred choice.

This requires us to consider this factor in the initial design of the marine hinges. Design the structure of the hinge in such a way that it can be flush mounted. For some infrequently used marine hinges, we can even design a separate cover for it, which is both aesthetically pleasing and safe.

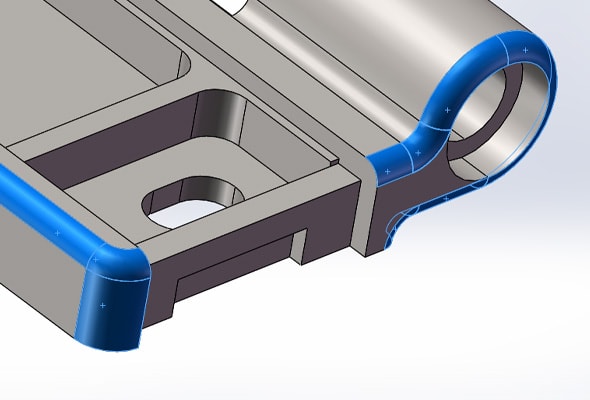

Considerations When Customizing Marine Hinges

#1-Material Selection:

It's essential to choose a material like stainless steel 316 for marine hinges due to its high corrosion resistance. This ensures that the hinge remains functional and maintains its appearance even in harsh saltwater conditions.

#4-Load Capacity:

Understand the weight the hinge will need to support to avoid overburdening and eventual failure. Always select a hinge with a slightly higher load capacity than the expected maximum weight for safety margins.

#2-Size and Specifications:

Determine the precise size and specifications of the hinge based on its intended use and the load it will bear. Incorrect sizing can lead to structural vulnerabilities and decreased lifespan. If these parameters are not clear, please contact us.

#5-Aesthetic Considerations:

When you make a request for custom marine hinges, the aesthetic aspect is indispensable. If you have a unique aesthetic, be sure to speak with one of our designers and it will be your masterpiece.

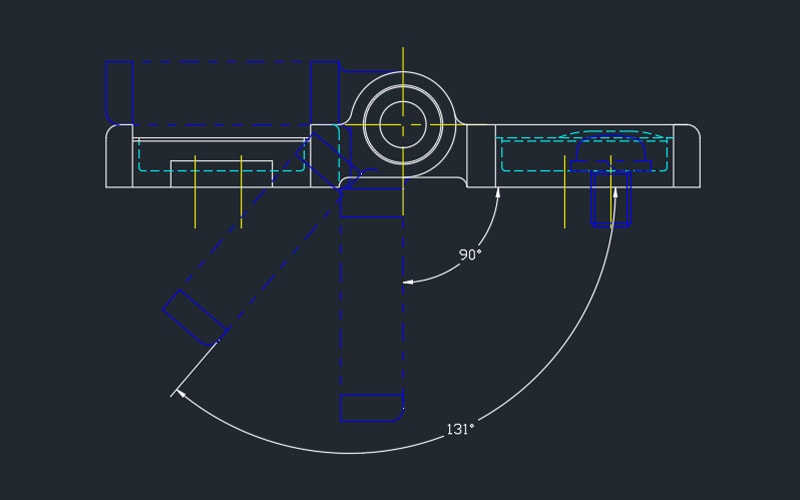

#3-Range of Motion:

Decide on the hinge's range of motion, considering whether it should open to a full 180 degrees or have a limited arc. The chosen range should suit the specific application and space constraints of the installation area.

#6-Mounting Mechanism:

Ensure that the hinge design includes a robust mounting mechanism suitable for the material it'll be attached to. A solid mounting ensures that the hinge can bear weight and function optimally without causing structural damage.

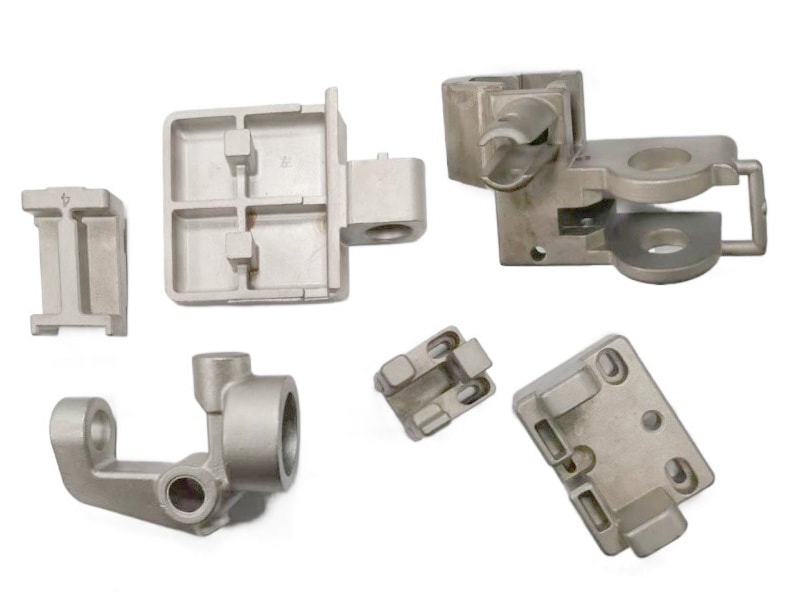

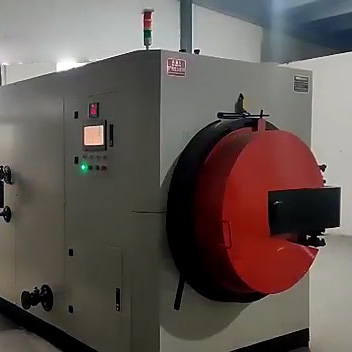

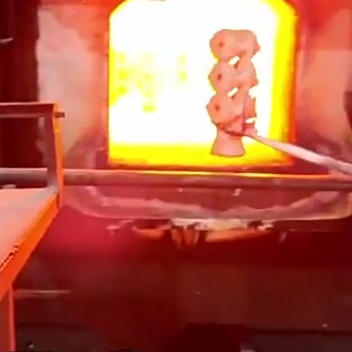

Production Process

316 Stainless Steel Marine Hinges are made with precision casting process. Precision casting, also known as investment casting or lost-wax casting, is a complex multi-step process. Here are the primary steps involved in this technique:

- No.10, Juyuan II Road, Shangtun, Liao Bu Town, Dongguan City, Guangdong Province, China

- +86 136 5038 7336

- [email protected]

Send us a message

Send us a message if you have any questions or request a quote.