Strap hinges and traditional door hinges differ significantly in structure, load capacity, and installation method.

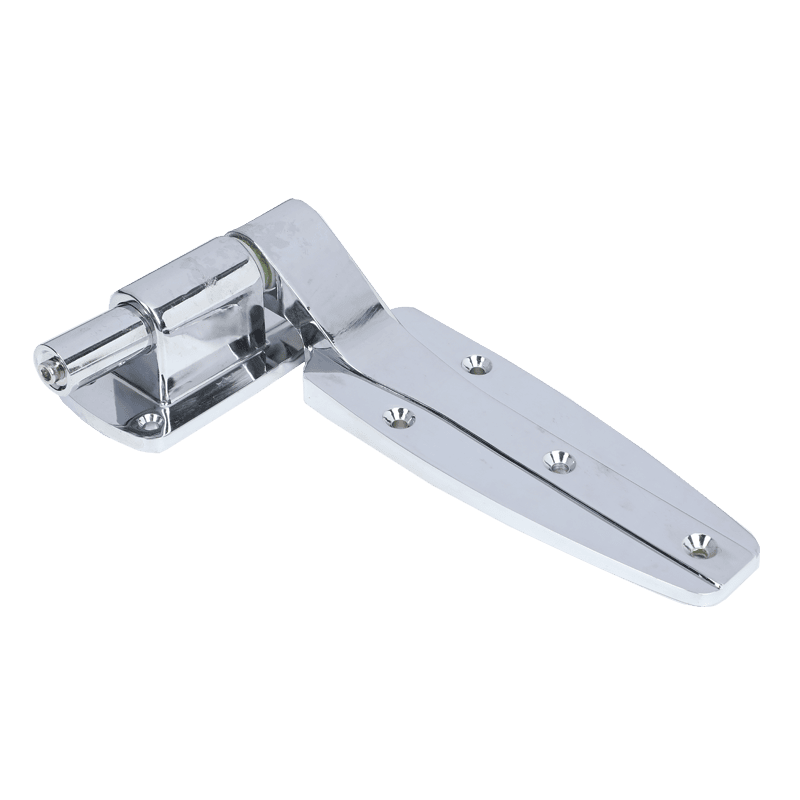

Strap hinges are distinguished by their long, narrow, often triangular leaf design, allowing higher load support and easier surface mounting, making them suitable for industrial and heavy-duty applications.

Keep reading to discover which hinge type is best for your industrial operation needs.

Introduction to Industrial Hinges

Industrial hinges serve a critical role in the secure and stable operation of doors, panels, and enclosures in manufacturing and machinery. Among the many hinge types, strap hinges and traditional door hinges are commonly misunderstood as interchangeable, though their use cases differ considerably in the industrial world.

Strap hinges, with their elongated and triangular leaf structure, offer greater support for heavy or wide doors. In contrast, traditional door hinges are often found in standard doors and equipment panels that don’t demand high structural load-bearing.

Strap hinges feature extended leaf lengths and surface-mount convenience, whereas traditional hinges rely on mortised installation and compact support.

Structural Differences Between Strap and Traditional Hinges

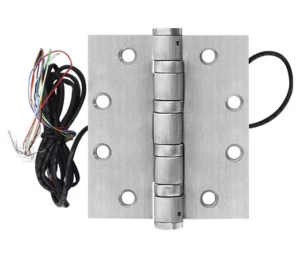

The most apparent difference lies in the leaf design. Strap hinges are engineered with long, narrow, and typically triangular-shaped leaves. These features allow them to distribute weight more evenly across a larger surface area, making them ideal for heavy, oversized industrial doors. Traditional hinges, by contrast, are usually rectangular and smaller, built for standard weight and daily use applications.

Another key structural distinction is in how the knuckle and pin are integrated. Strap hinges usually have more robust knuckles with thicker pins, enabling them to handle high-torque motion and repeated heavy-duty use without wear. Traditional hinges might offer multiple knuckles, but they lack the extended arm necessary for high-leverage applications.

Hinge Geometry and Engineering

| Feature | Strap Hinges | Traditional Hinges |

|---|---|---|

| Leaf Shape | Long & Triangular | Square or Rectangular |

| Load Distribution | Wide Area Support | Centralized |

| Installation Surface Area | Extended Arm Coverage | Limited Area |

| Torque Resistance | High | Medium |

Application Scenarios in Manufacturing and Equipment

Strap hinges are the preferred solution in industrial fields that require the management of large, heavy, or high-frequency access doors. These include trailer door hinges for logistics and transport equipment, cold storage room hinges in food and pharma facilities, and climatic test chamber hinges used in lab-grade environmental testing machines.

Traditional hinges still find their place in industrial applications, but mostly where structural demands are lighter. Think small machinery doors, service panels, or indoor equipment compartments.

Strap hinges are widely used in industrial environments like test equipment, transport containers, and climate chambers, thanks to their unmatched load-bearing ability and robust support.

Installation Methods and Industrial Efficiency

Unlike traditional hinges that require precise mortised installation, strap hinges are surface-mounted, meaning they can be directly screwed or welded onto the door and frame. This not only reduces installation time but also allows for easier hinge replacement during maintenance.

For industrial buyers prioritizing production efficiency and downtime reduction, this distinction is critical. Strap hinges, especially weld on hinges, are often pre-installed on the outer surface of machinery doors, saving hours in production and repairs compared to recessed hinge types.

Strap hinges simplify industrial assembly and maintenance by enabling direct surface mounting, unlike mortised traditional hinges.

Load Capacity and Mechanical Performance

In industrial scenarios, the ability to support high loads without deformation or mechanical failure is paramount. Strap hinges are specifically engineered for this, using thick-gauge metals and extended leverage arms to handle substantial door weights.

A strap hinge on a heavy equipment enclosure or metal testing chamber can support up to several hundred kilograms without needing additional reinforcement. Traditional hinges would fail under such conditions unless used in groups or combined with other structural supports.

Strap hinges outperform traditional hinges in supporting industrial-grade door weights, offering superior mechanical strength.

Customization and Design Flexibility

Many industrial applications require hinges to be tailor-made for fit, finish, or function. Strap hinges offer this flexibility—whether it’s stainless steel for corrosion resistant hinges, or aluminum alloys for lightweight installations such as aluminum hinges. Factories like IHINGES can provide customized 3D models, pre-drilled holes, custom logo markings, and treated finishes.

Traditional hinges, being more standardized, typically offer less flexibility. This limits their adaptability to complex or custom industrial designs.

Strap hinges offer high customization potential—perfect for industrial equipment with specific structural or branding requirements.

Visual and Functional Industrial Aesthetics

While appearance might be secondary in industrial contexts, some equipment—like control cabinets or custom machinery—benefit from strong design aesthetics. Strap hinges can offer a rugged, mechanical look that aligns with the machine’s branding or visual design.

Unlike basic square hinges, strap hinges can be designed with decorative cutouts or geometric patterns. This is particularly useful for clients looking to display equipment in exhibitions or demo labs.

Strap hinges add a rugged visual element to industrial equipment, enhancing design presentation alongside mechanical function.

Maintenance and Replacement Considerations

In industrial environments, downtime equals loss. One of the biggest advantages of strap hinges is that they can be replaced quickly. Surface-mounted designs eliminate the need to unmount the entire door or panel—just unbolt and install a replacement hinge.

Moreover, factories can carry spare strap hinges in stock, reducing delivery time. Traditional hinges, especially mortised versions, often require more time and precision during replacement.

Surface-mount strap hinges make hinge replacement faster and more efficient, reducing downtime in industrial operations.

Strap Hinges vs. T Hinges and Piano Hinges

Strap hinges are often compared to T hinges, which are essentially a type of strap hinge with one rectangular and one triangular leaf. While T hinges are more suitable for gate installations or flush-mounted doors, strap hinges offer greater leaf length and load support.

Piano hinges, also known as Aluminum Geared Continuous Hinges, span the entire length of a door edge, offering uniform support across the vertical axis. These are ideal for enclosures needing consistent hinge motion without sagging, such as equipment panels or instrument boxes.

Strap hinges differ from T and piano hinges by offering higher spot load support and more robust point-to-point mounting.

Cost-Benefit Analysis for Industrial Buyers

From a purchasing perspective, strap hinges may have a slightly higher upfront cost than standard hinges. However, the ROI is higher due to reduced maintenance, increased durability, and fewer replacements over time.

When buying at scale from an industrial hinge production base like IHINGES, manufacturers can negotiate custom hinge solutions and bulk pricing, helping maintain low per-unit cost while meeting quality requirements.

Strap hinges provide better long-term value for industrial buyers who prioritize durability, customization, and ease of maintenance.

Conclusion

Strap hinges deliver the strength, flexibility, and durability required in industrial environments, standing apart from traditional hinges in both form and function.