Heavy-duty piano hinges are the backbone of industrial door systems and equipment enclosures.

Heavy-duty piano hinges must be made from steel, feature through holes for secure mounting, and have protective surface finishes like military spec coating. These features ensure the hinge can support large, heavy components in demanding environments.

Understanding the structural and performance features helps avoid failure in critical applications.

What Is a Piano Hinge and How Does It Work?

Piano hinges, also known as continuous hinges, are designed to run the entire length of the objects they connect. They consist of two symmetrical leafs joined by a central pin, offering full-length support along doors, panels, and lids. Unlike traditional hinges placed at intervals, piano hinges distribute weight and stress evenly across the joint.

This type of hinge is widely used in industrial enclosures, climate test chambers, and sheet metal cabinets due to its durability and alignment precision. In contrast to butt hinges, which are better suited for small or domestic applications, piano hinges provide superior structural integrity in demanding environments.

Piano hinges operate by distributing force evenly across the full length of a panel, reducing stress points and extending the hinge’s lifespan.

Industrial Functionality

For industrial buyers, especially those working with equipment housings or control panels, piano hinges eliminate the sagging or misalignment often caused by multi-hinge systems. They are commonly integrated into the framework of climatic test chamber hinges or other precision equipment where uniform motion is essential.

With proper material and treatment, piano hinges ensure stability, high load resistance, and long-term reliability even in high-vibration or high-cycle applications.

Why Choose Piano Hinges Over Traditional Hinges in Industrial Equipment?

Piano hinges provide a continuous load path, unlike traditional hinges that apply force at a few concentrated points. In industrial applications, this continuous contact enhances mechanical strength and reduces wear and tear. Equipment like heavy doors or panel covers performs better and lasts longer when supported across the entire length.

Moreover, they minimize maintenance, a crucial factor for large-scale manufacturing facilities and equipment rental providers.

Piano hinges eliminate hinge point stress, improve alignment, and reduce operational noise in industrial applications.

Maintenance and Operation Benefits

In facilities where constant temperature and vibration are present—such as in cold storage systems—hinge reliability is non-negotiable. Standard butt hinges or detachable hinges may fail or loosen over time. Continuous hinges, however, maintain even alignment and reduce hinge fatigue.

This durability makes them especially effective for sealing-sensitive enclosures like climate chambers or industrial refrigeration doors.

The Importance of Steel Construction in Heavy-Duty Applications

Material is a critical selection factor in industrial hinge applications. Heavy-duty piano hinges are most effective when constructed from high-strength materials like cold-rolled or stainless steel. These materials offer superior resistance to fatigue, tensile stress, and torsion forces compared to lighter metals such as aluminum.

Steel hinges also resist deformation and perform reliably under high-cycle usage, which is typical in automated doors and high-traffic panels.

Steel piano hinges are preferred in industrial settings due to their exceptional strength, wear resistance, and load-bearing capacity.

Material Comparison

| Material | Strength | Corrosion Resistance | Ideal For |

|---|---|---|---|

| Steel | High | Moderate (coated) | Industrial gates, equipment panels |

| Aluminum | Medium | High | Lightweight doors, electronics |

| Stainless Steel | Very High | High | Marine and food-grade environments |

While aluminum hinges are corrosion-resistant and lightweight, they are not suitable for heavy-duty doors, especially when exposure to impact or constant opening and closing is expected.

How to Determine Load Capacity of a Piano Hinge?

Load capacity is influenced by hinge length, material thickness, and mounting method. Most heavy-duty steel piano hinges can support from 200 lbs up to over 600 lbs per linear foot, depending on gauge and mounting integrity. Proper engineering analysis is essential when choosing hinges for equipment doors or trailers.

You should always check the manufacturer’s technical datasheet for exact specifications and recommended load-bearing limits.

To calculate load capacity, evaluate hinge material, gauge, mounting method, and total door weight per hinge foot.

Application Planning

For example, a 6-foot-long steel piano hinge with a 0.090″ gauge can safely carry heavy-duty access panels on machines or cold storage doors. It’s vital to consider dynamic forces, especially if the object will open and close frequently or bear shock loads.

This makes piano hinges ideal for supporting components like trailer door hinges, where vibration and repetitive movement require durable continuous support.

Through Holes vs. Solid Leaf Design: Which is Better?

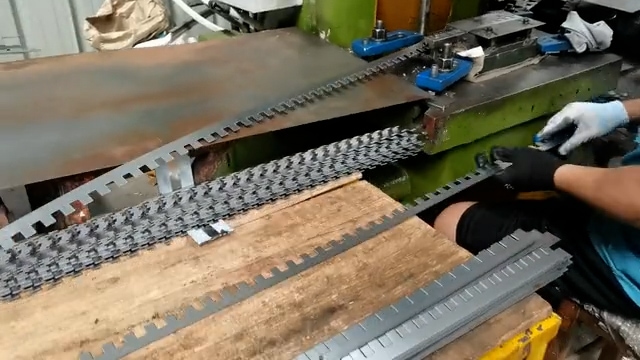

Through holes are pre-drilled openings in the hinge leaf that allow for mechanical fastening using screws, rivets, or bolts. Hinges with through holes offer better retention, easier installation, and greater mechanical reliability. In contrast, solid leaf piano hinges require welding or custom drilling, which adds labor and risk.

Through-hole piano hinges enable faster, more secure installations using bolts or screws, improving load distribution and serviceability.

Installation Flexibility

For manufacturers of control boxes or climatic chambers, through-hole hinges mean easier integration into sheet metal components. This is essential for rapid assembly-line processes.

Weld-on versions are more appropriate for permanent fixtures or when working with thick gauge metals—but they lack flexibility in field servicing or replacement.

Surface Treatments and Finishes for Corrosion Resistance

Heavy-duty piano hinges must withstand harsh environments—whether exposure to moisture, temperature extremes, or chemical agents. That’s why surface treatments like zinc plating, black oxide coating, and military spec finishes (e.g., MIL-DTL-16232) are essential. These protect against corrosion, extend hinge life, and maintain aesthetic consistency.

Military spec finishes are especially suited to mission-critical equipment that may be deployed outdoors or near corrosive substances.

Protective finishes guard against corrosion and oxidation, especially in harsh industrial and marine environments.

Environmental Compatibility

Consider a piano hinge for use in marine environments or refrigeration units—humidity and salinity will compromise untreated hinges. Therefore, surface treatment is not optional; it’s a requirement for industrial-grade hinges.

Many clients sourcing marine hinges or chamber doors rely on black zinc-coated or passivated stainless-steel piano hinges to ensure longevity.

Choosing the Right Thickness and Width of a Piano Hinge

Thickness affects both strength and flexibility. Typical heavy-duty hinges range from 0.060″ to 0.125″. Thicker hinges provide greater support but require more torque to move. Width is equally important: wider hinges distribute forces more evenly across the joint and help maintain door alignment.

Select hinge thickness and width based on door weight, frequency of use, and mounting structure.

Matching Hinge Specs to Application

For example, a 0.090″ thick, 2-inch wide piano hinge is ideal for a medium-weight industrial refrigerator door. Over-specifying adds weight and cost, while under-specifying leads to premature failure.

Always align hinge specs with the design requirements of the equipment, particularly when working with access panels that require frequent servicing.

Customization Options for Industrial Piano Hinges

Many industrial clients require custom hinges tailored to their equipment’s shape, usage frequency, and aesthetic design. Custom options include:

-

Specific length or cutting-to-size

-

Custom hole patterns

-

Powder coating or anodizing

-

Laser-etched logos

-

Reinforced knuckles or pin locks

Customized piano hinges can be tailored to your exact mechanical, visual, or branding needs.

B2B Value in Customization

Clients in sectors like industrial ovens or environmental test chambers often demand CAD-based hinge designs with tight tolerances and corrosion-resistant finishes. Providing these customization options improves product-market fit and speeds up integration into the client’s workflow.

Industrial Applications of Heavy-Duty Piano Hinges

From access panels to sealing systems, piano hinges are used across multiple industrial sectors. Specific applications include:

-

Control boxes

-

Environmental test chambers

-

Cold storage room doors

-

Industrial ovens

-

Trailer or container doors

Piano hinges are ideal for precision equipment doors, especially in high-usage, high-stress industrial environments.

Industry Usage Scenarios

Heavy-duty cold storage room hinges typically rely on long piano hinges to maintain a consistent airtight seal. In trailer or container applications, these hinges reduce misalignment caused by frequent use and environmental exposure.

Industries such as aerospace, HVAC, and military manufacturing often specify piano hinges in their equipment designs due to their proven performance and load reliability.

Quality Standards and Certifications to Consider

When sourcing heavy-duty piano hinges, check for quality standards like ISO 9001, RoHS compliance, and military specifications. These certifications ensure consistent performance, safe materials, and reliable manufacturing processes.

Certified hinges ensure compliance with industrial and government standards, reducing risk in critical operations.

Trust and Verification

Certifications can be a key factor when dealing with regulated industries. For example, hinges used in medical-grade equipment or military testing facilities often require full traceability and batch documentation.

Suppliers offering quality control reports, materials testing, and inspection records provide more transparency—making your sourcing decisions safer and easier.

Conclusion

Heavy-duty piano hinges offer unmatched reliability in industrial applications. Choose steel construction, through holes, and protective finishes to ensure performance under pressure.