Stamped industrial hinges are built for precision and durability. But how exactly are they manufactured from sheet metal?

Industrial hinges are produced through a sequential process: laser cutting, deburring and polishing, press-forming, manual assembly, and inspection. This method ensures durability, precision, and consistent performance across high-volume production lines.

Let’s walk through the complete production process, from raw sheet to finished hinge.

How Is the Raw Material Prepared for Hinge Stamping?

The first step in manufacturing stamped industrial hinges is preparing the raw material—usually stainless steel, cold-rolled steel, or aluminum. In most cases, laser cutting is used to slice entire metal sheets into hinge-sized blanks with high precision and minimal waste. This method provides clean edges and allows for rapid customization based on hinge dimensions.

For mass production runs, mold-based shearing may also be used to reduce costs and increase throughput. Both methods yield consistent blanks, ensuring a reliable base for the subsequent forming processes.

Laser cutting allows for flexible, precise shaping of hinge blanks, especially for custom or low-volume orders. Mold-based shearing offers faster throughput for bulk manufacturing.

Laser Cutting vs Mold Shearing

| Method | Advantages | Use Case |

|---|---|---|

| Laser Cutting | High precision, clean edges, flexible | Custom orders, prototypes |

| Mold Shearing | Fast, cost-effective for volume | Mass production |

This stage lays the foundation for hinge quality. Clean cuts and exact dimensions are essential, especially for complex styles like marine hinges or trailer door hinges, where fit and sealing are critical.

Why Is Polishing Important After Cutting?

After the hinge blanks are cut, they typically undergo deburring and surface treatment in a rotary tumbling barrel. This step removes sharp edges, burrs, and any slag produced during the cutting process. Polishing not only improves worker safety but also enhances the cosmetic appearance of the final hinge.

A smoother surface contributes to better forming accuracy in later bending stages. It also plays a role in corrosion resistance, particularly in products like outdoor industrial hinges, which face harsh environmental exposure.

Polishing ensures that hinge blanks are safe to handle, look professional, and are ready for accurate forming in subsequent stages.

Benefits of Polishing

-

Removes burrs and imperfections

-

Prepares surface for bending

-

Improves corrosion resistance

-

Enhances product aesthetics

Skipping this step may result in assembly issues or sharp edges that could compromise functionality and safety. This is particularly important for precision hinges like climatic test chamber hinges, where performance and reliability are non-negotiable.

How Are Hinge Blanks Bent Into Shape?

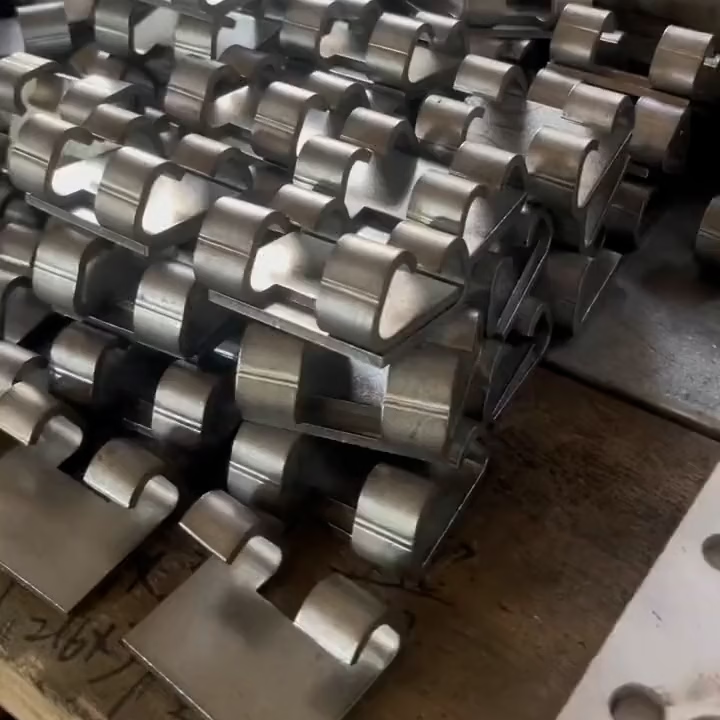

With clean, polished blanks ready, the next step is bending the metal into hinge form using single-operation stamping dies. Each press is typically dedicated to a specific bending action, such as forming the hinge leaf or knuckle. Multiple stamping stages may be necessary depending on hinge complexity.

Mechanical presses ensure consistent angles, tight tolerances, and high repeatability. Operators load each blank into the press manually or via a semi-automated feed system.

The bending process forms the defining structure of the hinge, including the knuckles and mounting flanges, through one or multiple press operations.

Each die is tailored to a specific hinge type—whether it’s a flat butt hinge, a long piano hinge, or a curved specialty hinge. Accurate bending is especially critical for hinges like aluminum hinges, which can be prone to cracking under improper stress.

Common Bending Operations

| Operation | Function |

|---|---|

| Leaf Forming | Bends flat blank into hinge leaf |

| Knuckle Rolling | Forms cylindrical sections for pin insertion |

| Offset Bending | Adds space for overlapping leaves |

By the end of this stage, the hinge pieces have taken their final shape and are ready for assembly.

How Are the Hinge Parts Assembled Together?

Once the hinge components are formed, they are transferred to the assembly line, where technicians insert the hinge pins and align the leaves. This process may be fully manual or aided by jigs and fixtures to ensure alignment and speed.

The two leaves are matched carefully, and a pin—usually steel or stainless steel—is inserted through the knuckles to form the hinge’s pivot point. For removable designs like detachable hinges, the assembly may include split knuckles or quick-release pins.

Assembly involves aligning the formed hinge leaves and inserting the hinge pin to complete the mechanical structure of the hinge.

Proper alignment and smooth pivot action are tested during this phase. Hinges that are not properly assembled may have excessive play or friction, leading to failure during use.

This step is particularly important for more robust models like heavy duty hinges, which require precise alignment to support large doors or panels under load.

What Happens Before Hinges Are Shipped Out?

The final step in hinge stamping is quality control and packaging. Each hinge undergoes a visual inspection to check for deformities, misalignment, or incomplete forming. Some factories also perform functional testing to ensure that the hinge opens and closes smoothly under standard loads.

Once approved, the hinges are packed into boxes or pallets according to customer specifications and prepared for logistics. Export clients—such as those ordering from North America or Singapore—often request special packaging or labels for inventory tracking.

Each hinge is visually and functionally inspected before being packaged and prepared for shipment, ensuring only quality units reach the customer.

Final QC Checklist

-

Knuckle alignment

-

Smooth rotation

-

Surface finish

-

No burrs or sharp edges

-

Correct dimensions

This step ensures that industrial clients—such as test chamber manufacturers or sheet metal fabricators—receive hinges ready for immediate use, whether standard or custom-built solutions like Take-Apart Hinges or Electro-Galvanized Hinges.

Conclusion

From laser cutting to inspection, stamped industrial hinges go through a controlled, step-by-step process to ensure reliability, strength, and high-volume productivity.