Some clients want hinge samples before paying for mold fees. Is it possible to make samples without a mold?

Yes, it’s possible to make hinge samples without molds using manual or semi-automated processes. However, these methods are more complex, less precise, and often require a small sample fee. While mold-free samples can help verify design intent, they may not fully reflect final mass production quality.

Let’s explore when and how hinge samples can be made without molds, and what trade-offs to consider.

Is the Client’s Concern About Mold Fees Reasonable?

Client concerns over mold costs are understandable, especially for custom hinge designs or low-volume projects.

Mold fees are often a major upfront cost. For clients unfamiliar with manufacturing, it feels risky to pay before seeing a product, which makes their hesitation reasonable.

Why Clients Push Back on Mold Fees

For many first-time or cautious buyers, paying for a mold before seeing a sample feels like a leap of faith. When sourcing internationally, such as from China, clients like J. Oldham often expect to verify quality and design functionality before committing to large orders or tooling costs.

This concern is valid. Mold fees typically start from a few hundred dollars and can reach thousands, depending on the complexity of the hinge design. For example, custom cold storage room hinges or climatic test chamber hinges often require precision molds to ensure air-tight sealing and mechanical integrity.

Understanding the Manufacturer’s Viewpoint

From the manufacturer’s side, molds are not just costs—they’re assets that enable consistent, high-precision, and scalable production. Building a mold involves CAD design, CNC machining, fitting, and testing. Without this foundation, it’s nearly impossible to ensure that the final product meets client expectations for fit and function.

Therefore, when a client asks to skip mold-making, it creates a real challenge: how can we make them feel confident in the product without losing time and money on uncertain development?

| Perspective | Client’s View | Manufacturer’s View |

|---|---|---|

| Mold Fee | High risk, unsure of output | Necessary investment for accuracy |

| Sample Expectation | Wants to see quality before investing | Needs tools to make accurate samples |

| Ideal Outcome | Low-cost sample to verify design | Secure commitment before mold-making |

Can Hinge Samples Be Made Without a Mold?

Yes, but the process is more complex and has design limitations.

Hinge samples can be made manually or using shared tooling, but they are less precise, less attractive, and often more labor-intensive. This process involves trade-offs in finish, fit, and time.

Manual Sample Creation: What It Involves

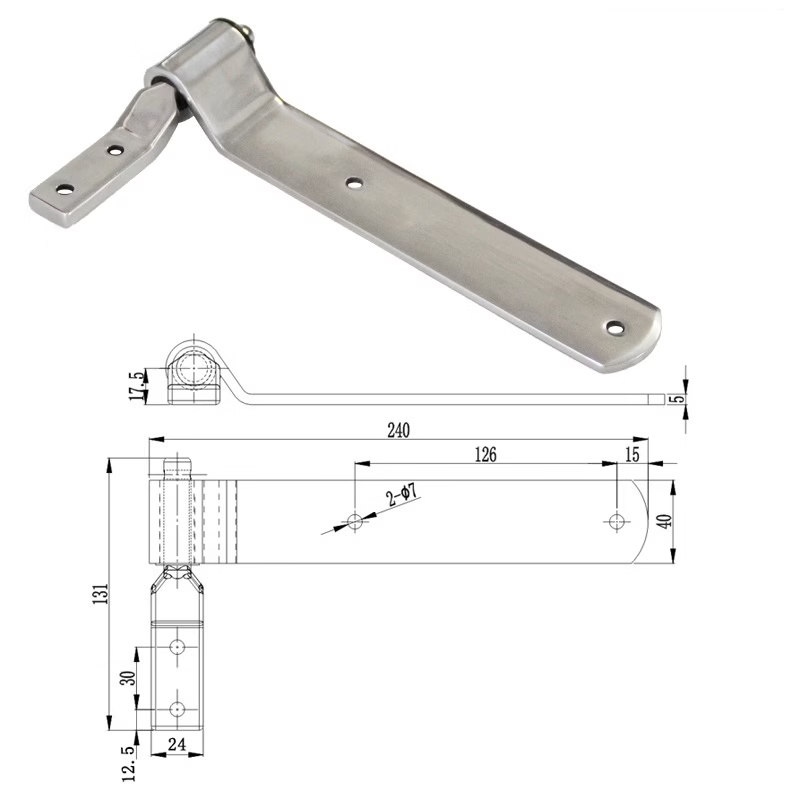

In cases where mold costs are a barrier, manufacturers like IHINGES may choose to create hinge samples manually. This could involve using CNC milling, basic punching dies, or even partially compatible jigs from existing projects. It works particularly well for simpler components like butt hinges or detachable hinges where structural geometry isn’t too complex.

However, this method is time-consuming. It relies on skilled labor to ensure dimensional accuracy, and while the final product may look decent, it’s rarely production-grade. Details like surface polish, hole alignment, and edge precision are often slightly off.

What Are the Risks?

Manual sample production without a mold often leads to compromises. Features like curved edges, tight folds, or exact tension in moving joints can be hard to replicate. This is particularly true in precision products like adjustable torque stainless steel hinges or marine hinges which require tight mechanical tolerances for safety or environmental resistance.

Also, manual production doesn’t reflect the scalability of the design. A sample made by hand might function correctly, but that doesn’t mean it can be produced efficiently at volume.

In some cases, manufacturers might opt to create a temporary soft mold—less durable and cheaper than a full mold—just to deliver a more realistic sample.

Why a Sample Fee Still Applies Without a Mold

Even mold-free samples require time, materials, and labor—making a small fee necessary.

A mold-free hinge sample usually requires a sample fee. This fee is lower than mold costs but covers material, manual work, and setup. It ensures commitment and serious intent from the client.

The Economics of Sample Production

Creating a custom sample without a mold still involves costs: technical drawings, material selection, machine time, assembly, and shipping. In B2B manufacturing, especially for complex parts like heavy duty hinges or trailer door hinges, each of these steps can be expensive.

The sample fee—often ranging from $50 to $200—helps offset these costs. It also signals the client’s seriousness. From our experience at IHINGES, clients who are willing to pay a modest fee are more likely to move into bulk production.

Balancing Trust and Cost

As a manufacturer, we want to support clients and win their trust. That’s why we often agree to produce hinge samples without full mold investment—but only after receiving a sample fee. This approach gives clients a tangible product to evaluate while ensuring we don’t operate at a loss.

For example, in a recent case, a client needed a custom take-apart hinge sample but was hesitant to commit to a mold. We designed a simplified prototype using shared tooling, charged a small fee, and delivered a sample that met 90% of the design goals. The client approved and placed a full order shortly after.

| Type of Cost | Mold Fee | Sample Fee (No Mold) |

|---|---|---|

| Purpose | Full production tool | Trial sample verification |

| Cost Range | High (>$500) | Low-to-moderate ($50–$200) |

| Reusability | Yes, for mass production | Limited, one-time use |

| Delivery Speed | Slower (10–15 days) | Faster (3–7 days) |

Conclusion

Making hinge samples without molds is possible—but with trade-offs in precision and finish. A small sample fee balances cost and commitment.