Choosing the right electrical panel hinge is essential for performance, durability, and industrial safety.

The best electrical panel hinge depends on load requirements, environmental conditions, and compliance standards such as NEMA and IP ratings. Common hinge types include butt, concealed, torque, and piano hinges, each suited to different access, security, and space constraints. Material selection (stainless steel, aluminum, or zinc alloy) also plays a critical role in hinge durability and performance.

Selecting the correct hinge ensures system integrity and simplifies long-term maintenance.

What Are Electrical Panel Hinges and Why Are They Critical?

Electrical panel hinges serve as mechanical joints that connect an enclosure door to its frame, allowing controlled rotation and access to internal components. However, unlike simple residential door hinges, these are engineered for demanding industrial environments. Their responsibilities go beyond mere movement—they ensure proper sealing, load bearing, and equipment protection.

These hinges contribute to maintaining NEMA and IP ratings by helping to preserve consistent gasket compression, especially when used with corrosion resistant hinges or marine hinges in outdoor or high-humidity environments. Selecting the wrong hinge could compromise not only the enclosure’s function but also its compliance with safety standards.

Electrical panel hinges are critical for ensuring access control, mechanical support, and environmental sealing in industrial enclosures.

Industrial-grade panel hinges must withstand harsh environments, frequent use, and potential tampering. A high-performance hinge can handle thousands of cycles and integrate seamlessly with the rest of the enclosure hardware, such as locks and door latches. For instance, in telecommunications cabinets or chemical processing plants, the wrong hinge material or design can lead to early failure or downtime.

Engineering Focus on Functionality

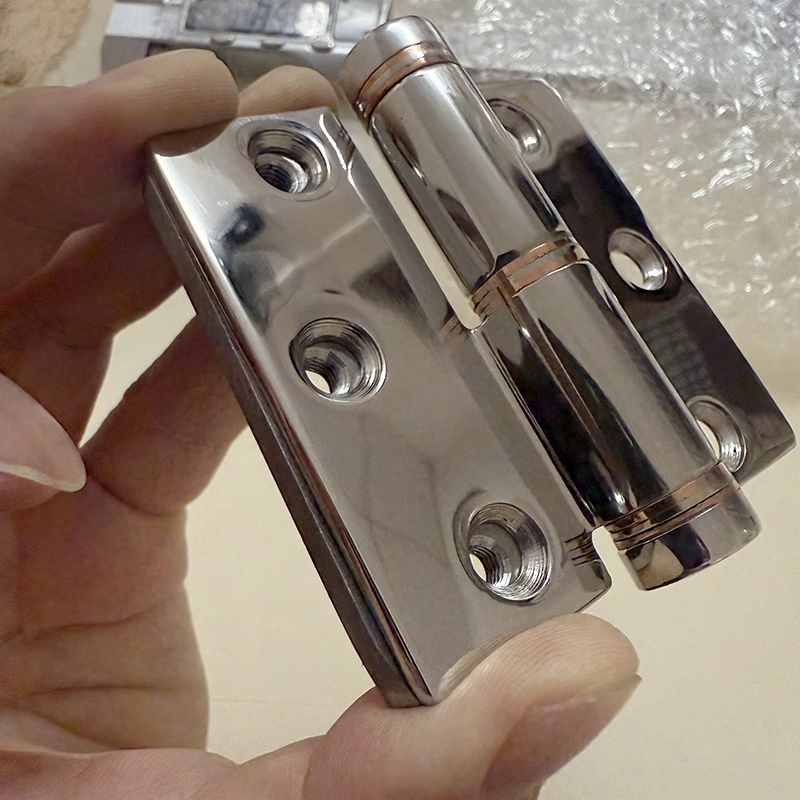

Unlike decorative hinges, industrial panel hinges are chosen based on mechanics: torque resistance, cycle rating, and environmental exposure. Materials like 316 stainless steel are preferred for corrosive settings, while Aluminum Geared Continuous Hinges are ideal where lightweight performance and sealing across long door edges are required.

More Than Just a Hinge

They often play a secondary role in safety—holding doors open (torque hinges), allowing fast removal (detachable hinges), or preventing unauthorized access (concealed hinges). Choosing a hinge with the correct form factor and function is essential for long-term reliability and security.

Common Types of Electrical Panel Hinges and Their Applications

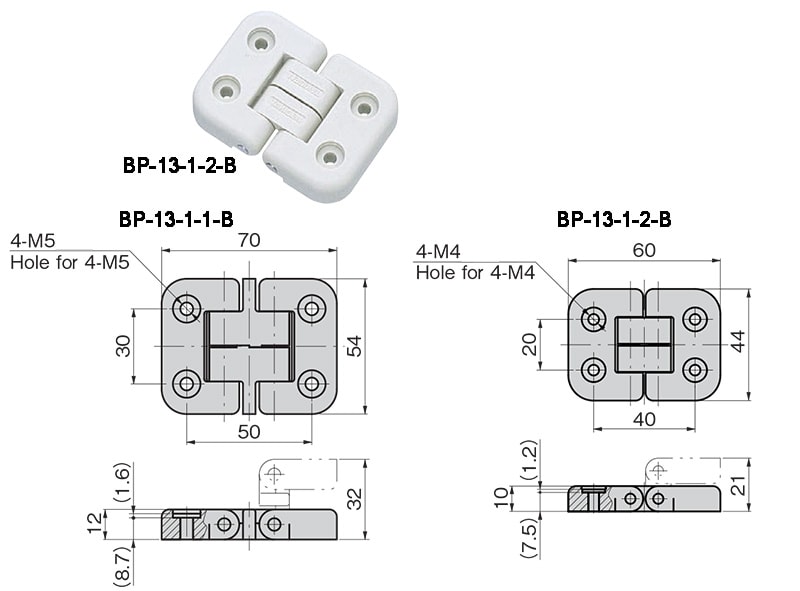

Electrical panel hinges vary by structure, function, and the demands of the specific application. Selection should consider load capacity, opening angle, ease of installation, and environment.

For example, piano hinges provide full-length support for heavy or tall doors, while detachable hinges allow technicians to quickly remove doors for unobstructed access during maintenance. The right hinge ensures efficient access and operational reliability, even in environments with vibration or exposure to corrosive agents. Key types include butt, concealed, piano, offset, torque, and detachable hinges, each offering distinct benefits for different industrial applications.

Quick Comparison Table

| Hinge Type | Load Capacity | Best Use Case | Max Swing Angle | Security Level |

|---|---|---|---|---|

| Butt Hinge | 50–200 kg | General use, easy maintenance | 90° | Medium |

| Concealed Hinge | 50–150 kg | Tamper-proof, aesthetic systems | 180° | High |

| Piano Hinge | 100–500 kg | Heavy, tall doors requiring full support | 180° | Medium |

| Torque Hinge | 50–200 kg | Hold door at any angle | 90°–180° | High |

| Offset Hinge | 50–300 kg | Full door clearance in tight spaces | 270° | Medium |

| Detachable Hinge | 30–150 kg | Quick door removal without tools | 180° | Medium |

Applications range from factory control panels to cold storage room hinges in food and beverage facilities. For outdoor enclosures, outdoor industrial hinges with sealed designs and treated materials offer enhanced durability.

Materials and Finishes: Selecting the Right Hinge Material for Industrial Environments

The hinge material plays a pivotal role in its performance and longevity. It determines resistance to corrosion, mechanical stress, and environmental degradation.

Common hinge materials include stainless steel (for corrosion resistance), aluminum (for lightweight needs), carbon steel (cost-effective but needs coating), and zinc alloy (for complex shapes). Surface treatments like anodizing, passivation, and powder coating enhance their durability. Material selection for electrical panel hinges must align with environmental exposure, mechanical load, and corrosion risks.

Material Comparison Table

| Material | Corrosion Resistance | Weight | Cost | Common Use Case |

|---|---|---|---|---|

| Stainless Steel | Excellent | Medium | $$$ | Food processing, marine, pharma |

| Carbon Steel | Poor (unless coated) | Heavy | $ | General indoor industrial |

| Aluminum | Good | Lightweight | $$ | Transport, aerospace |

| Zinc Alloy | Fair | Medium | $$ | Custom designs, indoor |

| Brass | Good | Heavy | $$$$ | Hazardous zones, decorative |

For example, when selecting hinges for an offshore platform cabinet, marine hinges made from 316 stainless steel offer superior chloride resistance.

Industry Standards for Electrical Panel Hinges

In industrial environments, compliance with standards ensures safety, quality, and legal access to regulated markets. Hinges must align with the same enclosure protection levels as the cabinet or box they support.

Three major standards govern electrical panel hinges: NEMA (North America), IP (international), and RoHS (EU). Certified hinges maintain the integrity of enclosure ratings (NEMA/IP) and support environmental, safety, and legal compliance.

Key Certifications

-

NEMA Ratings: Enclosure protection against dust, water, and corrosion (e.g., NEMA 4X for outdoor use).

-

IP Ratings: IP65 or IP66 means complete dust protection and high water resistance.

-

RoHS Compliance: Restricts hazardous substances in EU markets.

A hinge that fails to comply can compromise the entire enclosure. Always cross-check certifications when selecting for sensitive applications such as renewable energy switchgear or pharmaceutical production.

How to Select the Right Hinge: A 4-Step Industrial Checklist

Selecting a hinge requires both technical understanding and application-specific insights. Following a structured checklist ensures functional fit and longevity.

Use this 4-step process to choose the correct electrical panel hinge:

-

Mechanical Fit: Check door weight, hinge orientation, rotation angle, and dimensional constraints.

-

Environmental Resistance: Match material to operating environment (outdoor, corrosive, temperature extremes).

-

Regulatory Compliance: Verify required NEMA, IP, or RoHS standards.

-

Installation & Safety: Choose welding, bolting, or lift-off features based on access, tamper resistance, and aesthetics.

Field Example

A control panel in a dusty, high-traffic warehouse may require a detachable hinge for easy access and Adjustable friction hinges to hold the door open safely . Failing to consider these details can result in frequent service interruptions or even system downtime.

Best Practices for Installation and Maintenance

Correct installation and regular maintenance are key to long hinge life and system integrity. Ensure proper hinge alignment, use suitable fasteners, and conduct periodic inspections to avoid premature failures.

Maintenance Checklist

-

Precise Alignment: Prevents stress and wear.

-

Proper Fasteners: Match materials to avoid galvanic corrosion.

-

Welding Best Practices: Avoid heat distortion or spatter in hinge mechanisms.

-

Lubrication: Especially for heavy-duty or outdoor applications; see Importance of Lubrication for Heavy-Duty Barrel Hinges for more tips.

Industry Applications: Where and How These Hinges Are Used

Electrical panel hinges are used across industries where access, safety, and environmental protection are critical.

| Industry | Hinge Type Example | Functionality Required |

|---|---|---|

| Manufacturing & Automation | Butt, Detachable | Vibration resistance, quick maintenance |

| Power Distribution | Piano, Offset, Weld on Hinges | High load-bearing, NEMA compliance |

| Transportation | Heavy Duty Truck Door Hinge | Shock/vibration resistance |

| Marine | Marine Hinges, 316 SS | Salt resistance, anti-corrosion |

| Telecom/Data Centers | Torque, Concealed Hinges | High cycle life, internal access only |

| Food & Pharma | Stainless Steel, Concealed | Washdown resistance, anti-bacterial finishes |

Partnering with a Reliable Hinge Manufacturer

Sourcing hinges from a specialized manufacturer ensures consistent quality, compliance, and performance.

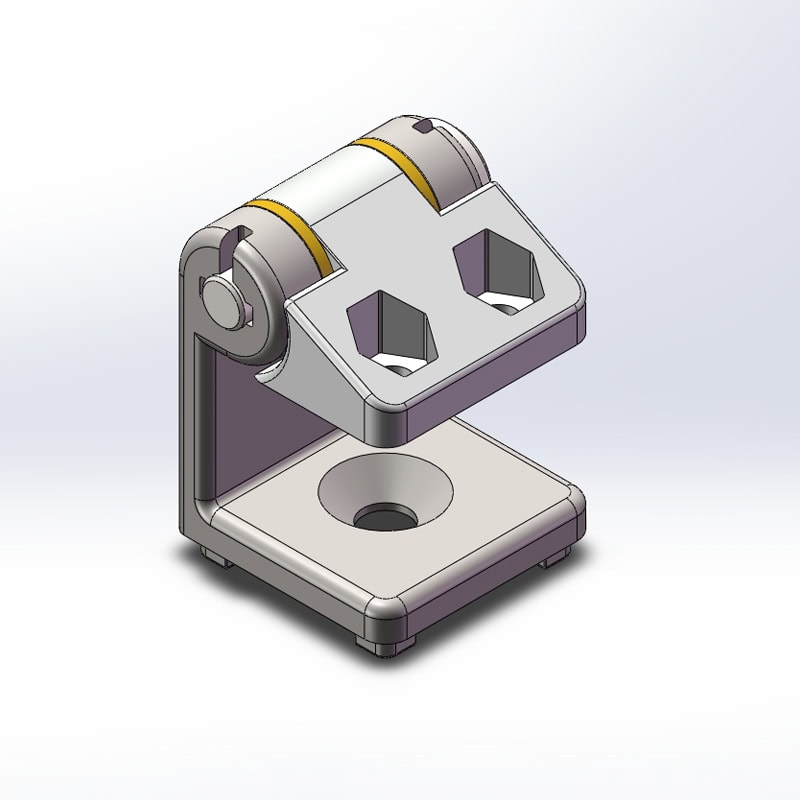

IHINGES offers over 700 customized hinge solutions with engineering support, 3D design services, and full compliance certifications.

From Electro-Galvanized and Hot-Dipped Hinges to precision staked hinge assemblies, partnering with IHINGES reduces sourcing risk and streamlines integration into your system designs.

Conclusion

Choosing the right electrical panel hinge isn’t just about movement—it’s about safety, compliance, and performance. With proper selection, installation, and sourcing from trusted manufacturers like IHINGES, your enclosure systems will function reliably, securely, and efficiently for years.