Weld-on hinges offer unmatched security and durability in demanding industrial applications.

Weld-on hinges outperform bolt-on types in tamper resistance, load capacity, and service life, making them ideal for heavy-duty industrial doors, gates, and enclosures.

Explore how weld-on hinges meet the rugged demands of modern industrial environments.

What Are Weld-On Hinges and How Are They Installed?

Weld-on hinges are specialized metal hinges designed to be permanently affixed to equipment or structures by welding rather than using screws or bolts. This method of installation fuses the hinge leaf directly to the metal surface of a door or gate, creating a tamper-proof and highly durable connection.

Unlike bolt-on hinges, which rely on mechanical fasteners, weld-on hinges do not loosen over time. They’re ideal for applications where vibration, movement, or tampering may otherwise compromise the reliability of the hinge. Industries dealing with high temperatures, heavy usage, or outdoor exposure often favor this hinge type for its solid performance and security.

Weld-on hinges are installed by fusing their leaf to a metal structure using heat, creating a permanent, high-strength joint suitable for industrial applications.

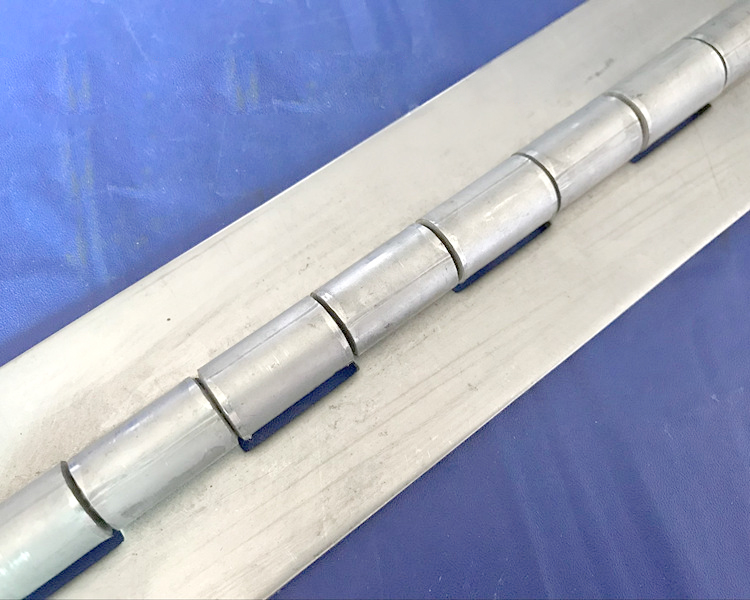

Weld-on hinges are commonly made from carbon steel or stainless steel and are available in numerous formats including Heavy Duty Continuous Hinges, Friction hinges in industrial applications, and barrel hinge designs. Their strength is not only due to the metal composition but also the welding process itself, which eliminates common failure points like screws or bolts. For this reason, many cold storage facilities, industrial ovens, and transport containers depend on weld-on solutions for hinge performance.

Why Are Weld-On Hinges Used for Security Applications?

Security is one of the primary reasons industrial designers choose weld-on hinges. Traditional hinges that use screws or bolts can be disassembled using common tools, leaving critical enclosures vulnerable to tampering or theft. Weld-on hinges, by contrast, offer a permanent solution that resists unauthorized access.

This makes them especially valuable in high-security applications like electrical panels, outdoor control boxes, military equipment, and detention facility gates. Even if a bad actor gains access to the outer area of a door or frame, the welded hinge provides no point of entry for tampering, cutting, or unscrewing.

Weld-on hinges eliminate access points for tools, making them tamper-resistant and highly secure for critical industrial enclosures.

For environments such as outdoor substations or sensitive communication cabinets, outdoor industrial hinges must combine strength with discretion. In such cases, invisible hinges or concealed weld-on variants are used. Furthermore, using options like Heavy Duty Truck Door Hinge adds robustness for mobile industrial applications where both security and shock resistance are required.

How Strong Are Weld-On Hinges Compared to Bolt-On Hinges?

Strength and load-bearing capacity are vital considerations for industrial hinges. Weld-on hinges excel in both areas because they distribute force directly into the door frame and panel without relying on bolt holes or mechanical attachments. This eliminates points of mechanical failure, particularly under constant use or weight.

Weld-on barrel hinges, in particular, are engineered to carry immense loads without sagging or bending. The addition of bushings or bearings, such as in ball bearing butt hinges, further improves performance under continuous movement.

Weld-on hinges provide higher load-bearing strength than bolt-on types, making them ideal for heavy-duty, high-frequency applications.

Load Capacity by Hinge Type (Approximate)

| Hinge Type | Load Capacity (per hinge) | Installation Type | Common Usage |

|---|---|---|---|

| Weld-On Barrel Hinge (7-barrel) | 600–1000+ lbs | Welded | Heavy doors, gates, truck compartments |

| Bolt-On Butt Hinge | 200–400 lbs | Screwed | Access doors, cabinets |

| Heavy Duty Detachable Barrel Hinge | 800+ lbs | Welded | Containers, machinery hatches |

Applications such as loading bay gates, large test chambers, and cold storage room doors demand hinges that won’t fail under weight. Weld-on options deliver that reliability without requiring frequent adjustment or reinforcement, unlike bolt-on alternatives which may loosen or warp under stress.

Where Are Weld-On Hinges Commonly Used in Industry?

The rugged design and performance of weld-on hinges make them a staple across various industrial sectors. In automotive manufacturing, they are frequently used in trailer doors and cargo compartments. In testing and laboratory environments, they are installed on heavy, sealed chambers where precise alignment and tight sealing are essential.

Other sectors like food processing, telecommunications, and heavy equipment manufacturing benefit from the strength and longevity of weld-on hinges. They are essential for doors that undergo high-frequency operation or are exposed to outdoor elements.

Weld-on hinges are used in sectors like automotive, telecom, cold storage, and industrial equipment where high strength and stability are critical.

Consider applications like:

-

Cold storage access doors using cold storage room hinges to maintain airtight performance.

-

Industrial cabinets using Electrical Panel Hinges with welded mounting for anti-vibration support.

-

Transport vehicles using Take-Apart Hinges for maintenance accessibility without compromising hinge durability.

Weld-on options are particularly favored for their compatibility with custom-fabricated metal doors, which often require precision alignment and robust connection points to ensure safe, repeatable operation.

How to Choose the Right Weld-On Hinge for Your Equipment?

Selecting the right weld-on hinge requires evaluating factors such as material, size, pin diameter, finish, and environment. For outdoor or corrosive applications, stainless steel — especially marine-grade like 316 Stainless Marine Friction Hinges — provides optimal resistance. Indoors, carbon steel with an electro-galvanized or hot-dipped finish may suffice.

Also consider motion type: friction, free-swing, or take-apart design. If adjustability is required, Adjustable friction hinges or adjustable concealed hinges are better suited.

Choose weld-on hinges based on load, environment, adjustability needs, and materials like stainless or carbon steel for long-term performance.

Key selection criteria include:

| Selection Factor | Options | Notes |

|---|---|---|

| Material | Carbon Steel, Stainless Steel (316, 304) | Stainless steel preferred for corrosive environments |

| Finish | Hot-Dip, Electro-Galvanized, Polished | Protects from rust and wear |

| Functionality | Friction, Take-Apart, Adjustable Torque | Determine based on door weight and usage frequency |

| Size & Load Rating | Pin diameter, leaf width, barrel count | Critical for safety and operational integrity |

For clients needing OEM customization or special dimensions, IHINGES offers custom heavy-duty long hinges and engineering support. Drawings, 3D modeling, and prototyping are available for tailored applications.

What Is the Difference Between Weld-On and Heavy Duty Bolt-On Barrel Hinges?

Although both weld-on and heavy-duty bolt-on hinges serve industrial markets, they differ significantly in installation, performance, and use-case flexibility. Bolt-on barrel hinges are easier to install and replace, making them ideal for projects requiring modularity. Weld-on hinges, however, are more robust and secure, particularly in high-risk or high-vibration environments.

Weld-on hinges offer greater strength and security, while bolt-on barrel hinges are easier to install and replace in modular equipment setups.

Comparison Table: Weld-On vs Bolt-On Barrel Hinges

| Feature | Weld-On Hinges | Bolt-On Barrel Hinges |

|---|---|---|

| Installation | Permanent (welded) | Removable (screws or bolts) |

| Security | Tamper-resistant | Moderate tamper resistance |

| Replacement | Requires cutting or grinding | Simple unscrewing |

| Applications | High-security, heavy-duty | Modular equipment, mid-duty use |

| Customization | High | Medium |

For example, clients using Electro-Galvanized and Hot-Dipped Hinges may prefer bolt-on if corrosion resistance is needed but replacement is expected. On the other hand, operations that must Replace Industrial Door Hinges less frequently will benefit from the rigidity and security of weld-on options.

Conclusion

Weld-on hinges provide unmatched strength, durability, and tamper resistance, making them ideal for demanding industrial environments requiring permanent, secure hinge solutions.