Weld-on barrel hinges are critical components in heavy-duty industrial access systems.

Choosing the right weld-on barrel hinges for heavy-duty applications depends on load capacity, material type, barrel size, and usage frequency. High-quality steel construction, precise knuckle tolerances, and proper pin size are essential for reliable performance in industrial environments.

Let’s explore how to make the right choice to match your equipment needs.

What Are Weld-On Barrel Hinges and Why Are They Ideal for Heavy-Duty Use?

Weld-on barrel hinges are cylindrical hinges designed to be permanently welded to metal surfaces, offering unparalleled strength and security in industrial environments. Unlike traditional screw-on hinges, weld-on versions are favored for high-load, high-use scenarios due to their robust construction and tamper-proof installation.

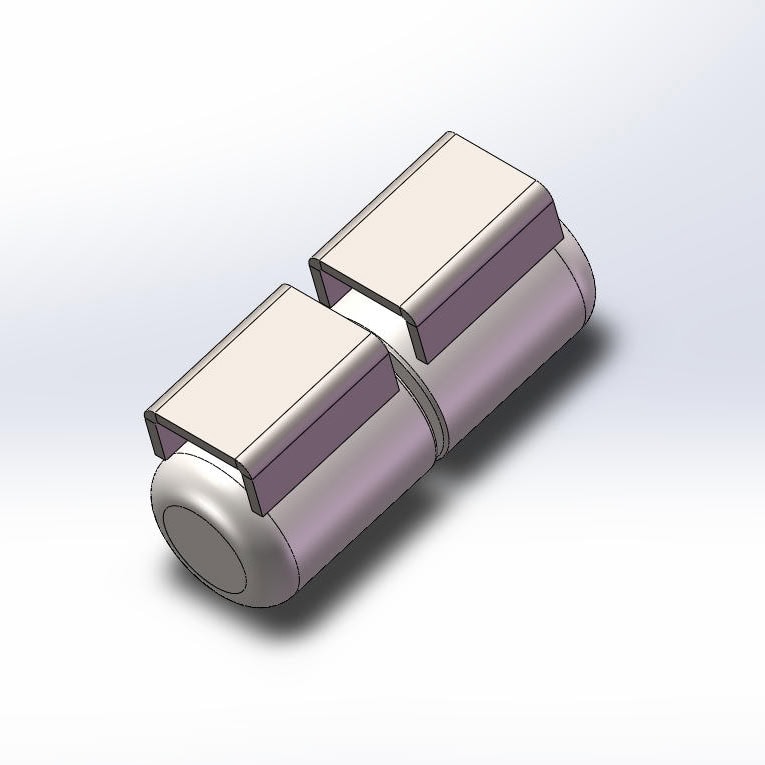

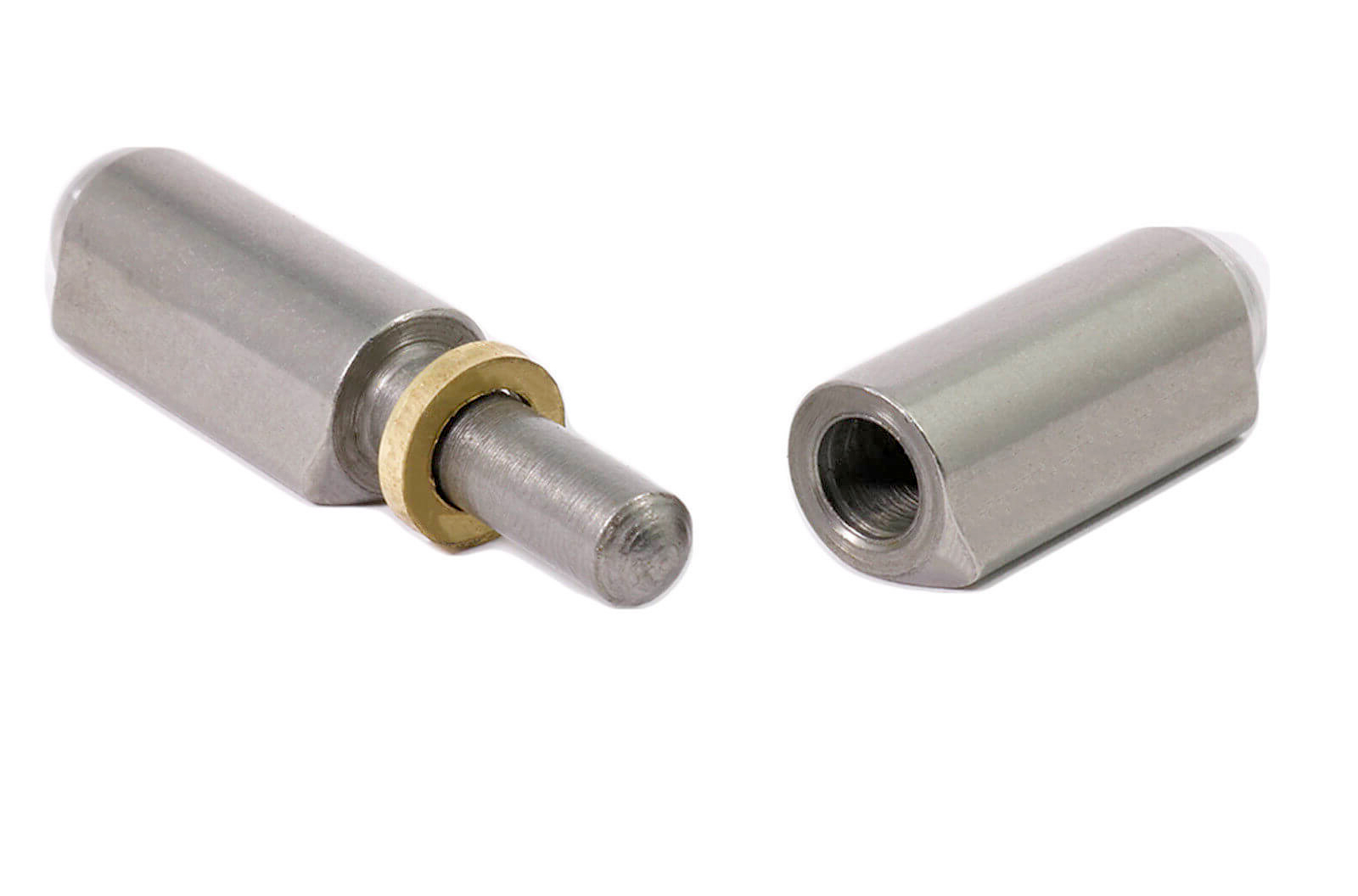

The typical weld-on barrel hinge consists of two leaf barrels—each containing a central pin or shaft and sometimes a bushing for smoother movement. Their simple structure enables them to handle heavy doors, gates, or access panels in applications like trailers, industrial enclosures, and mechanical gates. These hinges are especially suitable where long-term reliability is key, and where maintenance access is minimal.

Weld-on barrel hinges are ideal for heavy-duty use because they provide a permanent, load-bearing connection that resists wear, impact, and tampering—making them a go-to solution for industrial machinery and access points.

Key Factors to Consider When Choosing Heavy Duty Weld-On Barrel Hinges

When selecting the right weld-on barrel hinge for your application, it’s crucial to evaluate several mechanical and environmental factors. First and foremost is load capacity—the hinge must support the full weight of the door or gate while maintaining smooth operation over time.

Material choice is the next important factor. For indoor, non-corrosive environments, carbon steel may suffice. However, for outdoor or marine settings, stainless steel (especially 316 stainless marine friction hinges) is a preferred choice due to its corrosion resistance. Pay attention to barrel size and pin diameter, as these directly affect the hinge’s mechanical strength and rotational stability.

To choose the right weld-on barrel hinge, assess your door’s weight, the operating environment, the desired swing angle, and the hinge material. Stainless steel or galvanized finishes improve durability for outdoor or corrosive settings.

Common Applications of Weld-On Barrel Hinges in Industrial Settings

Weld-on barrel hinges are widely used in industries where strength, precision, and low maintenance are essential. These include the manufacturing of machinery doors, industrial gates, metal cabinets, and utility enclosures. A good example is the Replace Industrial Door Hinges project in heavy machinery service centers, where standard hinges fail under frequent use and vibration.

Another key application lies in industrial testing equipment, such as temperature and humidity chambers, where consistent door alignment and secure sealing are vital. Because weld-on hinges offer a tight, unshifting connection, they’re also preferred in transportation equipment—trailers, containers, and access panels in mobile machinery.

Weld-on hinges in industrial applications provide stability, strength, and long-term durability, especially where frequent movement or vibration is expected.

Pros and Cons: Are Weld-On Barrel Hinges Always the Best Choice?

Weld-on barrel hinges are not universally ideal. They offer strong mechanical benefits but come with trade-offs that buyers should consider. Pros include their ability to handle high loads, resistance to tampering, and low maintenance. When designed correctly, they last for years without the need for lubrication or adjustment.

However, there are limitations. Installation is permanent—once welded, repositioning is difficult. Inaccurate welds can cause misalignment or premature wear. Also, compared to adjustable concealed hinges, these hinges lack post-installation flexibility. For customers requiring field adjustability, adjustable friction hinges or concealed torque-controlled models may be more suitable. Weld-on barrel hinges offer unmatched strength but require accurate installation and are not adjustable, making them best for stable, heavy-duty settings.

How to Select the Right Size and Specifications for Your Project

Size selection begins by estimating the total load the hinges must support. For heavier doors, using multiple hinges (typically 2 to 3 per door) is common. Choose hinges with appropriate pin diameter and barrel thickness to match the load and frequency of use.

Don’t forget to account for environmental factors. Electro-galvanized and hot-dipped hinges offer excellent corrosion resistance for outdoor or marine use. It’s also essential to determine the opening angle your application requires—some hinges are designed for 90°, others for 180°, or even full rotation. Consult 3D drawings or technical specs when integrating into custom enclosures. To select the right hinge size, match the door’s load, opening frequency, and environmental exposure with the hinge’s material, pin size, and movement range.

Tips for Installation and Customization of Weld-On Barrel Hinges

Proper installation starts with accurate alignment. Before welding, mark the hinge positions carefully and tack weld first to ensure the swing path is smooth. A common error is welding at a slight angle, which causes the barrel to bind during operation. For specialized applications, some manufacturers, including IHINGES, offer custom heavy duty weld on hinges with design services and laser-engraved logos.

IHINGES also supports customers with CAD and 3D drawing services to simplify integration. If your application requires branding or non-standard sizes, customization ensures the hinge matches both form and function. Some clients request extended barrels for deep-panel installations or integrated stoppers for defined open positions. Accurate welding, use of jigs for alignment, and leveraging custom design services are key to achieving the best performance from weld-on barrel hinges.

Conclusion

Choosing the right weld-on barrel hinge ensures safety, efficiency, and longevity in industrial settings. Always match your application’s load and structure with the correct specs.