Heavy-duty pivot hinges are a very widely used type of hardware for industrial and commercial equipment. Although the items are small, they play a vital role in them. This is because the proper opening and closing of these equipment doors are completely dependent on the performance of the hinge.

Hinges are often classified into different types of hinges depending on their construction, function, materials, and installation methods. When classified according to the installation method, the two main methods are simply bolt-on and weld-on. This article will look at which mounting method is more appropriate for heavy-duty pivot hinges from a mounting method perspective.

What are the heavy-duty pivot hinges?

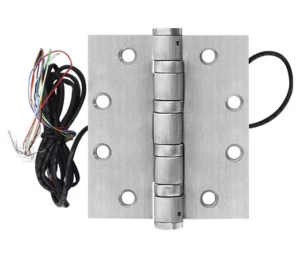

First, let’s figure out what a heavy-duty pivot hinge is. The important feature of this type of hinge is its load-bearing nature, which is reflected in its name. These hinges tend to be larger in size, especially in terms of the diameter of the pivot. This is because the pivot is the most important component in order to achieve the requirement of high load-bearing capacity.

The heavy-duty pivot hinge should be considered one of the most important parts of any door. It holds the weight of the door while still allowing you to open and close it easily. They act like a bridge between the door and the door frame. It holds the door securely to the frame and prevents it from coming out. There are numerous such hinges on the market today for industrial and commercial use. Each type of hinge has a different design, characteristics, and capabilities. On this basis, they are used in a variety of applications.

What are the characteristics of heavy-duty pivot hinges?

In the introduction above, we mentioned that an important feature of the heavy-duty pivot hinge is its load-bearing properties. Its load-bearing performance is much stronger than the general butt hinges. And it is mainly used on doors of large equipment. For example, Industrial Ovens, High & low-temperature test chambers, Thermal Shock Test Chambers, and so on. So they are the type of heavy-duty hinges.

In addition, such heavy-duty hinges are often made of high-strength materials. For example, stainless steel 304, stainless steel 316, or zinc alloy material. Zinc alloy material is less strong than the previous two materials. However, its plasticity is very strong, and the size of the produced product is almost the same as the design size. Heavy-duty pivot hinges produced with this material can save customers a lot of money while meeting performance requirements.

Stainless steel 304 or 316 is the best material for strength. It is stronger than zinc alloy material, both in terms of load bearing and corrosion resistance. And it requires almost no maintenance during long-term use. Because this material has the function of self-healing, it will not be corroded.

Factors that affect how heavy-duty pivot hinges are installed

Next, I will describe what factors affect the way heavy-duty pivot hinges are installed. So that you have a reference when you are shopping for these hinges.

-

Mounting

If bolt mounting is used, we need to determine the hole location beforehand. We need to drill the holes in the door and door frame, and then bolt the hinges on. This process requires careful planning and operation. If we use welded installation, we can directly weld the hinges to the surface of the door and door frame. This is convenient and quick.

However, this is only applicable to external installations. If you want to use welded installation on the inside of the door, it will be very difficult and not easy to replace. The bolt-on method can be easily replaced or removed for future improvements.

-

Load Capacity

Load-bearing capacity here refers to the individual load-bearing size of the hinge. In the actual installation process, a full range of factors may need to be considered. From there, the actual load-bearing size of the hinges needed is determined. For example, if a door has an important 100KG, we do not assume that a total load-bearing size of 100KG for all hinges will be sufficient. Rather, there should be a redundant load-bearing capacity. For example, 150KG or even 200KG.

-

Applications

If the welded installation is used, it is not suitable for permanent applications where movement is frequent. Therefore, heavy-duty pivot hinges for this type of installation can provide strength and security for doors or gates. Hinges are usually welded to the metal frame and door. You can often find hinges like these on farm gates, armored vehicles, prison gates, vault doors, fire doors, and many other such applications.

-

Aesthetic appeal

This may be a factor that we tend to overlook. But customers always remind us of it. They always choose the coolest, best-looking heavy-duty pivot hinge with the same performance. iHinges produces hinges that have great aesthetic appeal regardless of the hinge type.

What are bolt-on and welded installations?

As the name implies, bolt-on hinges are screwed or bolted in place, while welded hinges are welded to a metal surface. Welded hinges are replacing bolt-on hinges in a variety of applications due to their ease of installation. Both heavy-duty welded hinges and bolt-on hinges offer certain advantages, which are dictated by their design.

The use of bolt-on mounting is sometimes designed for temporary applications. This way when it is time to disassemble, the bolts are simply removed. They can also be used for doors that are temporarily erected outdoors and quickly disassembled when they need to be moved. They are also suitable for applications that require periodic disassembly for various reasons. These hinges are usually perforated for mounting screws or bolts.

Which mounting method is suitable for heavy-duty pivot hinges

Based on the above, it should probably be clear to you which mounting method to use for your heavy-duty pivot hinges. The choice of bolt-on or weld-on mounting depends entirely on your actual application requirements. This factor discussed above is judged based on your actual application scenario. If you are still unable to decide which heavy-duty pivot hinges to color. We suggest you contact IHINGES engineering staff. They are experienced and trustworthy.

The company has been helping customers with similar hinge problems in various fields. This includes solution design, product advice, installation assistance, and selection help. Feel free to contact us anytime.

Why heavy-duty pivot hinges are better for welded installations

Welded hinges are welded to another metal surface. Welded hinges are also known as weldable hinges, barrel hinges, or lift-off hinges. There are different types of weld-on hinges or welded door hinges depending on their use. There are many other types of hinges. But why are welded door hinges still preferred in certain applications? It is because it is easy to install.

They do not require drilling and tapping. The hinges are aligned with the door and frame and then welded in place. No field drilling or tapping is required. They perform on all fronts. This means that in addition to providing an attractive way to attach metal doors, these hinges are strong, compact, and durable.

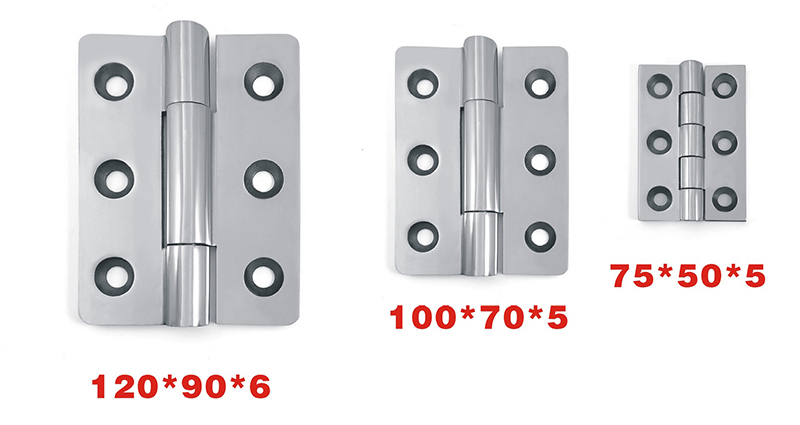

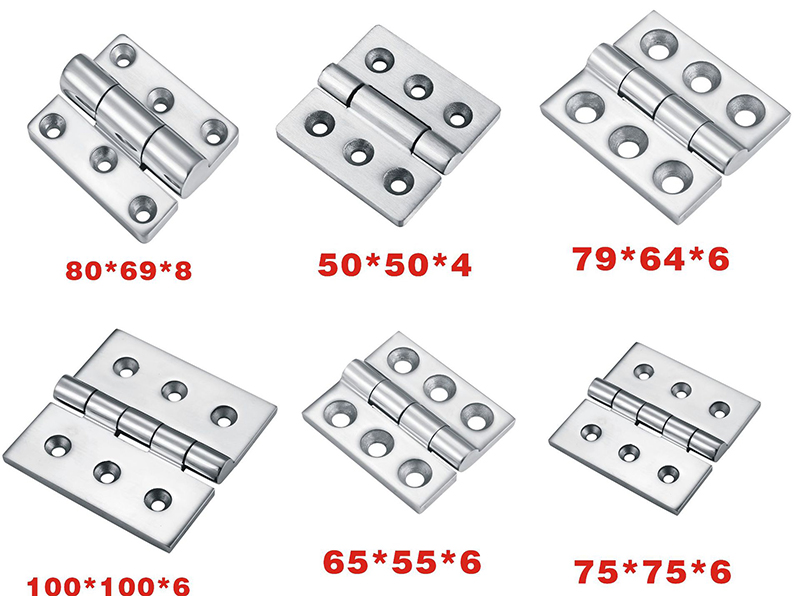

Welded hinges come in different types, sizes, features, and specifications and find their use in a wide range of applications.