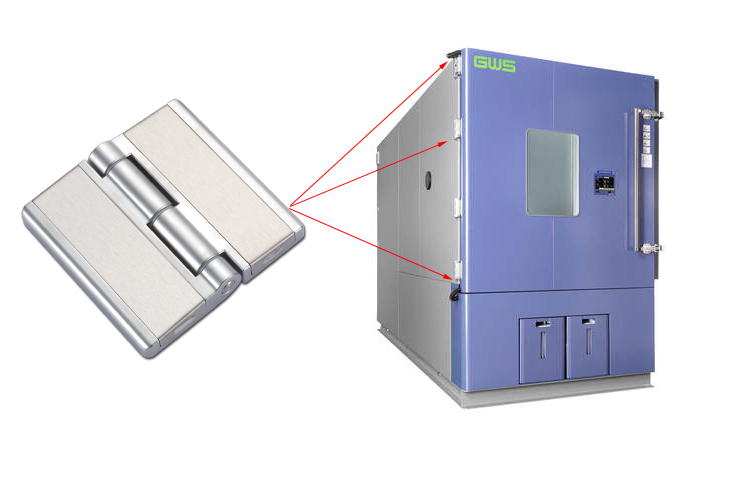

Thermal cycling chamber hinges are essential components of environmental chambers used for testing materials and products under extreme temperature conditions. These hinges must be carefully designed and maintained to ensure that the chamber remains airtight and that the door operates smoothly and consistently.

What are thermal cycling chamber hinges?

Thermal cycling chamber hinges are specialized hinges used in environmental chambers that are designed to test the ability of products and materials to withstand temperature extremes. These hinges are designed to enable the door of the chamber to open and close smoothly, while also maintaining an airtight seal that prevents the exchange of air between the interior and exterior of the chamber. This is essential for maintaining the desired temperature and humidity levels within the chamber. And for ensuring that test results are accurate and reliable.

What is the main function of thermal cycling chamber hinges?

The main function of thermal cycling chamber hinges is to enable the door of the chamber to be opened and closed repeatedly without compromising the integrity of the seal. The hinges must be able to withstand extreme temperature changes without warping or cracking. Or otherwise deteriorating, as this would compromise the airtight seal and result in inaccurate test results. In addition, thermal cycling chamber hinges must be designed to withstand the mechanical stresses of repeated opening and closing. As well as any vibrations or shocks that may occur during testing. Thermal cycling chamber hinges and environmental test chamber hinges are similar in function and have high temperature, sealing, and other performance requirements.

What types of materials are commonly used for thermal cycling chamber hinges?

Thermal cycling chamber hinges are typically made from materials that are able to withstand extreme temperatures and mechanical stresses. Common materials include stainless steel, aluminum, and various types of high-strength plastics. Stainless steel is particularly popular due to its resistance to corrosion and its ability to maintain its strength and integrity at high temperatures. Aluminum is also commonly used due to its high strength-to-weight ratio and its ability to dissipate heat quickly. High-strength plastics, such as polyamide or PEEK, are used in some cases where a non-metallic material is desired. Such as in applications where the hinges may be exposed to corrosive or caustic environments.

How are thermal cycling chamber hinges mounted and integrated into the chamber?

Thermal cycling chamber hinges are typically mounted directly onto the door and frame of the environmental chamber using screws or other fasteners. The hinges must be aligned properly in order to ensure a smooth and consistent operation. And care must be taken to ensure that the door and frame are properly aligned as well. In addition, the hinges must be integrated into the control system of the chamber, which regulates temperature, humidity, and other environmental conditions. This requires careful calibration and testing to ensure that the chamber is operating correctly and that test results are accurate.

What factors should be considered when selecting thermal cycling chamber hinges?

When selecting thermal cycling chamber hinges, several factors should be considered. These include the expected temperature range of the chamber, the frequency of use, the size and weight of the door, and any specific requirements or standards that must be met. In addition, the hinges must be compatible with the other components of the chamber, such as the door handle, latch, and seal. The durability and reliability of the hinges are also important considerations, as well as any additional features that may be required. Such as a self-closing mechanism or adjustable tension.

How often should the hinges be maintained?

The frequency of maintenance for thermal cycling chamber hinges will depend on several factors. Including the frequency of use, the operating conditions of the chamber, and the type of hinge used. In general, it is recommended that the hinges be inspected and lubricated regularly and that any signs of wear or damage be addressed immediately. Depending on the type of hinge, it may be necessary to replace the hinge or perform more extensive maintenance periodically. Such as cleaning and re-greasing.

What are some common maintenance and care procedures for chamber hinges?

Common maintenance and care procedures for thermal cycling chamber hinges include regular inspection for signs of wear or damage. Cleaning and lubrication, and proper alignment and adjustment. The hinges should be inspected regularly to ensure that there is no warping, or cracking. Or other signs of damage that could compromise the integrity of the airtight seal. Lubrication of the hinges is essential for maintaining a smooth operation and can help to prevent wear and damage over time. Care should be taken to use the correct type of lubricant for the hinge material, and to avoid over-lubricating. As this can attract dust and debris that can interfere with the hinge’s operation. Proper alignment and adjustment of the hinges are also essential for maintaining the integrity of the seal and ensuring that the door operates smoothly and consistently.

In addition to these basic maintenance procedures, it is important to follow any specific guidelines or recommendations provided by the manufacturer of the hinges or the environmental chamber. This may include instructions on how to clean or replace the hinges. How to adjust the tension of the hinges, or how to address any specific issues that may arise. Regular calibration and testing of the environmental chamber as a whole are also essential for ensuring accurate and reliable test results.

Can chamber hinges be customized to meet specific needs or requirements?

Yes, thermal cycling chamber hinges can be customized to meet specific needs or requirements. Manufacturers of these hinges can work with customers to design hinges that are tailored to their specific applications. Taking into account factors such as the expected temperature range. The frequency of use, and the size and weight of the door. And any other special requirements or standards that must be met. Customization may involve selecting different materials. Adjusting the size or shape of the hinges. Or adding specific features such as a self-closing mechanism or adjustable tension. By working with a manufacturer to design customized hinges. Customers can ensure that their environmental chambers are optimized for their specific testing needs. Resulting in more accurate and reliable test results.

Looking for a manufacturer of industrial hinges?

IHINGES is a professional industrial hinge manufacturer from China. IHINGES have industrial hinges for every usage scenario. We can also customize products with different specifications and functions for you. We have a professional R&D team and have done a lot of practical cases in the field of industrial hinges. If you are looking for an industrial hinge manufacturer, then you have come to the right place. Contact us now.