Industrial enclosure hinges play a crucial role in specialized equipment, ensuring functionality and security. Whether it’s for environmental testing chambers, climate control units, or industrial precision ovens, the installation of the right hinges is paramount. These hinges are specifically designed to support heavy doors, which are commonly encountered in such specialized equipment. In this comprehensive guide, we will delve into the factors to consider when choosing industrial enclosure hinges and provide valuable insights to help you make informed decisions. IHINGES, a leading manufacturer based in China, specializes in customizing hinges for industrial enclosures, catering to diverse customer requirements.

How to Choose the Right Industrial Enclosure Hinges

A. Factors to Consider:

Load-Bearing Capacity:

One of the most important parameters to consider when selecting industrial enclosure hinges is their load-bearing capacity. These hinges need to support heavy doors, ensuring smooth operation and long-term durability. It is essential to choose hinges with a load-bearing capacity suitable for the weight and size of the door.

Size Selection:

Determining the appropriate size of industrial enclosure hinges is crucial for proper installation and functionality. Factors such as door weight, dimensions, and material should be considered. Careful measurement and assessment ensure that the hinges fit precisely and provide optimal performance.

B. Types of Industrial Enclosure Hinges:

Overview of the Three Main Types:

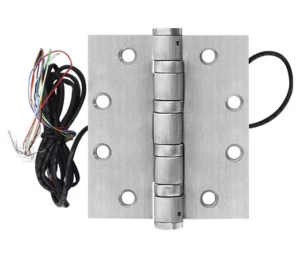

1. Butt Hinges: These hinges are the most common type used in industrial enclosures. They consist of two metal plates joined by a pin and provide stable support for heavy doors. Butt hinges are known for their simplicity and versatility, making them suitable for a wide range of applications.

2. Continuous Hinges: Also known as piano hinges, continuous hinges span the entire length of the door and provide seamless support. They offer superior strength, stability, and smooth operation. Continuous hinges are ideal for heavy doors that require consistent alignment and minimized stress points.

3. Pivot Hinges: Pivot hinges offer a unique design where the rotation axis is located away from the door edge. They provide excellent weight distribution, making them suitable for large, heavy doors. Pivot hinges allow for smooth and effortless door movement, even under substantial loads.

Differentiating Factors:

While the three main types of industrial enclosure hinges share the basic function of supporting doors, they differ in design, materials, and functionality. Butt hinges are commonly made of stainless steel or zinc alloy, while continuous hinges and pivot hinges can also be found in durable materials such as brass or aluminum. Each hinge type has its unique advantages and is suitable for specific requirements and door configurations.

C. Choosing the Right Grade of Industrial Enclosure Hinges:

In addition to considering the type and size of industrial enclosure hinges, it is essential to choose the appropriate grade. Hinge grades determine the strength, durability, and performance of the hinges in different applications. Factors such as environmental conditions, frequency of use, and durability requirements should be taken into account when selecting the grade of industrial enclosure hinges. Higher grades provide enhanced performance and longevity, making them suitable for demanding environments.

Understanding Commercial Industrial Enclosure Hinges

A. Differences between Commercial and Residential Hinges:

Commercial industrial enclosure hinges differ from their residential counterparts in several aspects. Commercial hinges are designed to withstand higher loads and frequent use, making them more robust and durable. They are typically made of heavy-duty materials such as stainless steel or solid brass. In contrast, residential hinges are often lighter and less durable, designed for standard residential doors with lower usage requirements.

B. Exploring Commercial Door Industrial Enclosure Hinges:

Commercial door hinges are specifically engineered to meet the needs of various industries, where heavy-duty doors are commonplace. These hinges offer features such as reinforced construction, increased load-bearing capacity, and superior durability. They are designed to handle the

demands of high-traffic areas and heavy doors, ensuring smooth operation and longevity.

Factors Contributing to Heavy-Duty Industrial Enclosure Hinges

A. Characteristics of Heavy-Duty Hinges:

Heavy-duty industrial enclosure hinges possess specific characteristics that enable them to withstand demanding conditions. These hinges are typically constructed with thicker materials and reinforced components to provide added strength and durability. They have high load-bearing capacities, ensuring reliable support for heavy doors. Additionally, heavy-duty hinges are designed to resist wear and tear, withstand frequent use, and maintain their functionality over extended periods.

B. Measuring and Calculating Load for Commercial Door Hinges:

To ensure the appropriate selection of commercial door hinges, it is essential to accurately measure and calculate the load requirements. Factors such as door weight, size, and usage patterns must be taken into consideration. By understanding the load-bearing capacity required for the door, suitable hinges can be chosen to ensure safe and reliable operation.

C. Materials Used in Commercial Door Industrial Enclosure Hinges:

Commercial door hinges are often manufactured using durable materials such as stainless steel, brass, or zinc alloy. Stainless steel is highly corrosion-resistant, making it suitable for harsh environments. Brass provides excellent strength and durability while adding an aesthetic appeal. Zinc alloy offers a balance of strength and affordability. Each material has its advantages, and the choice depends on specific application requirements.

Conclusion:

Selecting the right industrial enclosure hinges is crucial for the functionality and longevity of specialized equipment. Factors such as load-bearing capacity, size, hinge type, and grade should be carefully considered to ensure optimal performance and reliability. IHINGES, a trusted manufacturer of customized hinges, offers a wide range of solutions tailored to meet unique requirements. With their expertise and commitment to quality, IHINGES is dedicated to providing reliable and durable hinges for industrial enclosures. For all your industrial enclosure hinge needs, consult IHINGES and experience the assurance of high-quality solutions that meet your specific requirements.