Hinge pins are key components in most industrial hinge designs, but are they truly interchangeable?

Hinge pins can be interchangeable, but only if size, material, and design match precisely. Removable pins offer flexibility, but mismatches or permanent pins can lead to failure in demanding industrial applications.

Let’s explore the critical factors that determine whether hinge pins can be interchanged in heavy-duty or specialized industrial hinges.

Hinge Pins Must Match the Knuckle Size Precisely

Pin sizing is the first and most critical factor for interchangeability.

Pins that do not match the hinge knuckle’s diameter will cause mechanical failure. Always use correctly sized pins for safe, reliable operation.

In industrial settings such as climatic test chambers or trailer door hinges, hinges must maintain structural integrity under load and vibration. A pin that’s too small will allow movement between the knuckle barrels, leading to uneven wear, instability, and ultimately failure of the hinge.

On the other hand, a pin that is too large simply won’t fit into the knuckle’s central bore. Forcing it in may damage the knuckle or create stress points that lead to cracking during use, especially in heavy duty hinges. Precision manufacturing ensures tight tolerances, and these must be respected when sourcing replacement pins. Measuring the pin diameter and length using calipers is essential before attempting replacement.

Pin Materials Affect Performance and Compatibility

In industrial hinge use, material selection directly impacts performance, corrosion resistance, and service life.

Pin materials such as stainless steel, carbon steel, or brass must be selected based on load capacity, environment, and electrochemical compatibility.

Different industries require different material properties. For instance, marine hinges need corrosion-resistant materials like stainless steel due to exposure to salt and moisture, whereas carbon steel is often preferred in structural applications for its superior strength.

Incompatible material combinations between the pin and the knuckle can result in galvanic corrosion. For example, placing a brass pin into a carbon steel barrel can lead to dielectric interference over time, causing oxidation and weakening the joint. This is particularly concerning in high-precision environments like industrial refrigerator door hinges or cold storage room hinges, where failure is not an option.

Always match materials based on both mechanical and chemical compatibility, especially for hinges in controlled environments.

Not All Pins Are Removable

Some hinge designs do not allow for pin replacement.

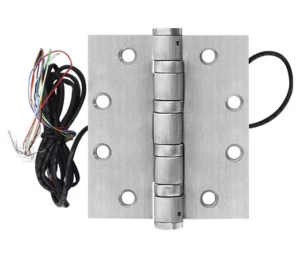

Permanent pins are built into the hinge and cannot be removed or replaced. Only hinges with removable pins allow interchangeability.

Many butt hinges and piano hinges in industrial equipment feature removable pins to simplify maintenance and repair. These can be extracted using a small punch or screwdriver and a hammer. This is advantageous in modular systems or machinery requiring regular disassembly.

However, special hinges or tamper-resistant designs often incorporate permanent pins for security or structural reasons. In such cases, the pin is swaged, welded, or press-fit during manufacturing and forms a permanent part of the hinge assembly.

Attempting to remove a permanent pin can damage the hinge and compromise safety. Therefore, always identify the pin type before planning replacements. A good industrial supplier or industrial hinge production base will provide technical drawings or datasheets to confirm this detail.

Universal Pins Are a Myth in Industry

Despite surface similarities, hinge pins are not universally compatible.

There’s no truly “universal” hinge pin in industrial use; dimensions and tolerances vary across manufacturers and hinge types.

A pin that fits one hinge model may not fit another, even if they look similar. This is especially true across different product lines such as detachable hinges vs. weld on hinges. Manufacturing standards can vary by region, manufacturer, and application, so it’s risky to assume compatibility without checking precise specs.

Industrial clients, especially those in OEM and equipment manufacturing, often work with custom or semi-custom components. When a pin needs replacement, always verify diameter, length, and material type using manufacturer part numbers or engineering drawings. Relying on visual comparison alone can lead to costly operational delays.

Tolerances Are Critical in Industrial Use

Precision engineering demands exact tolerances for all moving parts, including hinge pins.

Precision machining of pin and barrel tolerances ensures proper load transfer and alignment in mechanical systems.

Even a 0.1 mm deviation in diameter can introduce excessive play or prevent pin insertion. In soft close hinges or cam rise hinges, such tolerances are especially critical as they directly affect the hinge’s mechanical behavior and soft-close function.

Moreover, misaligned or poorly fitted pins can cause accelerated wear in automated machines, climate chambers, and electrical enclosures. Ensuring dimensional precision not only extends service life but also maintains safety and performance under continuous operation.

Always specify tolerances when requesting custom replacements from your hinge supplier.

Hinges and Pins Often Come as Matched Sets

In many industrial applications, hinges are designed with their pins as integral, matching components.

Manufacturers often design hinge leaves and pins as a matched set to guarantee performance and load capacity.

This is common in cold storage room hinges and precision enclosures where the hinge is expected to perform under temperature fluctuations and stress cycles. Attempting to fit a generic pin into a high-performance hinge can cause misalignment or loss of torque performance.

To ensure reliability, many hinge producers will not sell pins separately and instead supply the full hinge unit. If replacement is necessary, consult the original manufacturer or a reputable hinge supplier for matched components.

Environmental Exposure Impacts Pin Selection

Exposure to chemicals, moisture, or extreme temperatures will dictate pin material and finish.

Pins exposed to chemicals, moisture, or extreme temperatures must be corrosion- and fatigue-resistant.

Industrial environments are tough: salt spray, chemical fumes, extreme cold, and constant vibration all degrade materials over time. Pins must be chosen accordingly. For example, aluminum pins may corrode in marine environments, making them unsuitable for marine hinges. Stainless steel or coated steel is often preferred.

In climatic test chamber hinges, materials must resist repeated thermal expansion and contraction without fatigue. A poor pin choice can lead to stiffness, binding, or total failure during operation. Match the pin not only to the hinge but to the environmental conditions as well.

Removable Pins Enable Modular Maintenance

Quick disassembly is a major advantage in industrial maintenance cycles.

In settings like trailer doors or machinery panels, removable pins simplify maintenance and modular replacement.

Applications such as trailer door hinges or access panels in industrial ovens require frequent opening and removal. Hinges with removable pins allow for fast part swaps without requiring disassembly of the surrounding equipment. This reduces downtime and increases operational efficiency.

Removable pins also allow field technicians to carry a single type of spare pin compatible across multiple hinge models, provided the specifications are matched. Consult your hinge supplier for pin replacement kits that suit your operational needs.

Dielectric Interference Risks in Mixed Materials

Electrochemical reactions between dissimilar metals can degrade hinges over time.

Using different metals between pins and barrels can cause dielectric interference, leading to accelerated corrosion.

This issue is especially critical in sensitive environments like electronics enclosures, HVAC systems, and industrial refrigerator door hinges. Mixing aluminum with carbon steel, or brass with stainless, for example, can result in galvanic corrosion under moisture exposure.

Select matching materials or use isolating bushings or coatings to prevent contact. Suppliers specializing in high-performance hinges will typically provide advice on compatible materials for long-term durability.

Some Pins Require Special Tools for Removal

Industrial hinge pins may need more than just basic tools to remove.

Heavy-duty or rusted hinge pins may need punches, pullers, or lubricant to remove safely and avoid damage.

In field service environments—especially with weld on hinges or aging equipment—pins may seize due to rust or deformation. Specialized removal tools such as pin extractors, hydraulic pullers, or lubricants are essential to prevent damaging the hinge or surrounding panel.

Always consult technical documentation or contact your supplier for safe disassembly methods. Misusing tools or applying excessive force can compromise hinge performance and create safety hazards.

Conclusion

Hinge pins can be interchangeable in industrial settings—but only when carefully matched for size, material, design, and environment. Always confirm specifications before replacement.