In the industrial manufacturing sector, the diverse applications of piano hinges are essential to daily operations. These long, narrow hinges are crucial in creating connections that allow continuous motion. Different sizes of piano hinges enable different functionalities and finding the right one for a specific purpose can be a task.

Understanding the various sizes of piano hinges and their applications in the industrial manufacturing sector can optimize performance and enhance durability. With a wide range of lengths, widths, and thicknesses, there is a piano hinge suitable for every industrial need.

Now, let’s delve into these sizes, their features, and how they are specifically suited to the industrial manufacturing sector.

What Are the Common Lengths of Piano Hinges?

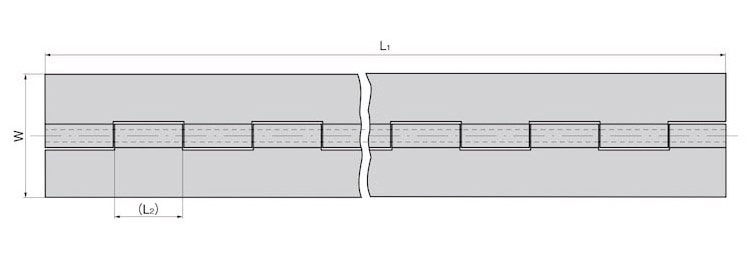

Piano hinges come in various lengths, commonly ranging from 6 inches to 72 inches. These length variations provide flexibility in industrial applications. Shorter lengths are often used in smaller machinery, while longer ones are used in heavy-duty equipment.

Different lengths can be tailored to meet the unique requirements of industrial machines. A short hinge might be ideal for a control panel, while a long hinge might be required for connecting larger components. Therefore, understanding these variations is key to selecting the most efficient solution.

What About Widths of Piano Hinges?

When it comes to widths, piano hinges offer another set of options. Widths typically range from 0.5 inches to 6 inches. These widths influence how much weight the hinge can bear and the degree of stability it provides.

Industrial manufacturing requires precise sizing, and the right hinge width can be paramount to the device’s functionality. From narrow widths that enable intricate movements to broader ones that provide more robust support, understanding this dimension is essential.

How Do Thicknesses of Piano Hinges Vary?

Thickness is another critical dimension in piano hinges, usually ranging from 0.035 inches to 0.5 inches. Thickness is directly related to the hinge’s strength and durability, which can be vital in the industrial sector.

Depending on the material and the application, thickness can be customized to enhance performance. Thin hinges might be used where flexibility is needed, whereas thick ones are used where heavy support is essential. Knowing these nuances ensures the longevity and efficiency of the equipment.

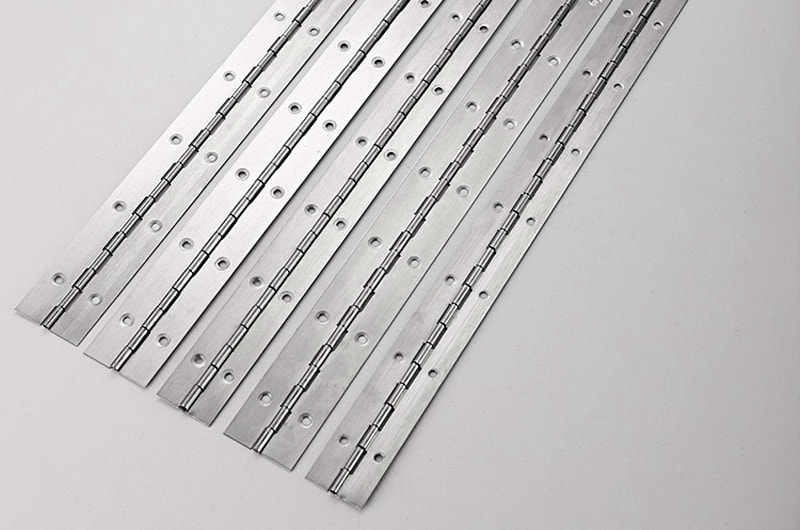

How Do Material Choices Affect Piano Hinges?

While steel is commonly used, other materials like stainless steel, aluminum, and brass are also popular. Material choices directly affect the corrosion resistance, weight, and aesthetic appearance of the hinges.

Different industrial environments require specific material attributes. For example, stainless steel might be preferred in a chemical environment for its corrosion resistance. Selection based on the material ensures that the hinge’s characteristics align with the industrial application’s needs.

Are There Custom Sizes Available for Specific Needs?

Custom sizing is often an essential aspect of industrial piano hinges. Custom sizes allow manufacturers to tailor hinges according to specific requirements, ensuring optimal fit and functionality.

Whether it’s a unique length, width, or thickness, custom sizes can fulfill specific industrial needs. This customization emphasizes the flexibility and adaptability of piano hinges, making them an invaluable component in the industrial manufacturing sector.

How Does Size Impact the Hinge’s Load Capacity?

The load capacity of a piano hinge is influenced by its size, material, and design. Both width and thickness play a critical role in determining how much weight a hinge can support.

Understanding load capacity is vital in the selection process. An inadequately sized hinge can fail under pressure, whereas a properly sized one ensures safe and smooth operation. Load capacity considerations guide the choice of size, leading to more efficient industrial applications.

How Are Piano Hinges Installed?

Installation methods can vary based on the size and type of piano hinge. Installation procedures must be considered in conjunction with size to ensure a secure and functional connection.

Whether riveting, welding, or using screws, the chosen installation method must align with the hinge’s size and application. Proper installation enhances the functionality and longevity of the hinge, contributing to overall industrial efficiency.

How Does Maintenance Vary with Different Sizes?

Maintenance is an often-overlooked aspect of piano hinges. Maintenance needs can differ with size, affecting the lifespan and efficiency of the hinge.

Larger, thicker hinges might require more regular maintenance, while smaller, thinner ones might be more resilient to wear and tear. Understanding these differences helps in selecting the right hinge and maintaining it effectively, ensuring continued industrial performance.

Conclusion

Understanding the various sizes of piano hinges, their features, and applications is essential in the industrial manufacturing sector. The diversity in lengths, widths, and thicknesses provides a plethora of options tailored to meet unique requirements, enhancing performance, durability, and efficiency.

You might also be interested: