Aircraft hinges may not be the first thing that comes to mind when thinking about aviation, but they’re essential to an aircraft’s function and structure. The complex engineering behind aircraft hinges allows for precise control of a plane’s movements, contributing to the efficiency, safety, and overall performance of the aircraft. In this blog post, we’ll delve into the variety and complexity of aircraft hinges, and why they are so important in aviation.

Every hinge on an aircraft, from those used on the ailerons, elevators, and rudder, to those on the accessory doors, is specifically designed and placed to serve a unique purpose. We’ll explore the common types of hinges used on aircraft, including their design, function, and how they’re constructed.

So, fasten your seat belts and prepare for an enlightening journey into the world of aircraft hinges. Let’s get started!

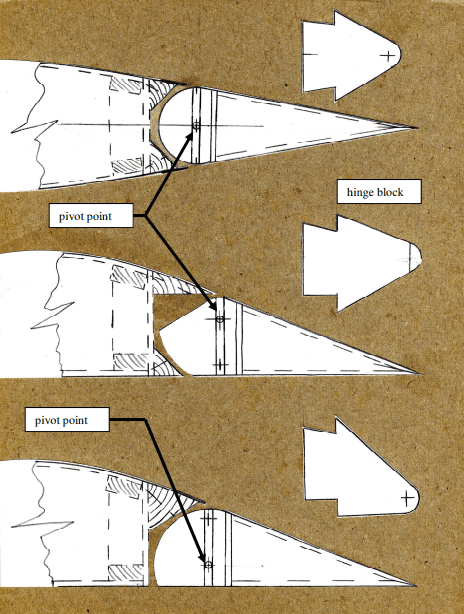

What are Center Hinged Aircraft Hinges?

These are typical for elevators and rudder use on aircraft. The center hinge operates on a pivot point, providing balance and enabling the control surface to move in the required direction. Center hinges need to be robust and resilient due to the constant force exerted on them during flights. For this reason, they’re often made from aircraft-grade plywood, which provides the necessary strength and durability.

In addition, center hinged designs employ a ‘hinge block’ design. This is a technique intended to simplify the manufacturing process while still providing a strong, functional hinge. The ‘hinge block’ also allows for easy replacement of the ‘bearing’ material if it ever wears out, which is an attractive feature for aircraft maintenance.

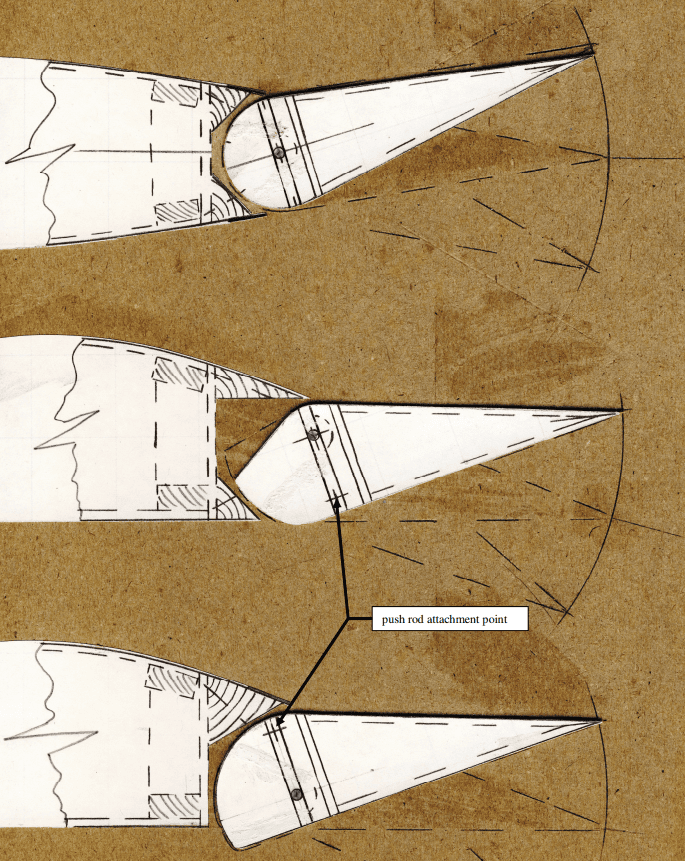

How about Top Hinged Aircraft Hinges?

Top hinged designs are usually utilized for ailerons. These hinges are strategically positioned on the top of the aileron to allow it to pivot upwards and downwards. The functionality of top hinged designs is pivotal in controlling the roll of the aircraft.

The unique feature of these hinges is their ability to handle significant loads and stress. They’re designed for ease of movement and longevity. As with center hinged designs, top hinged aircraft hinges often make use of a ‘hinge block’ design for simplicity, strength, and ease of maintenance.

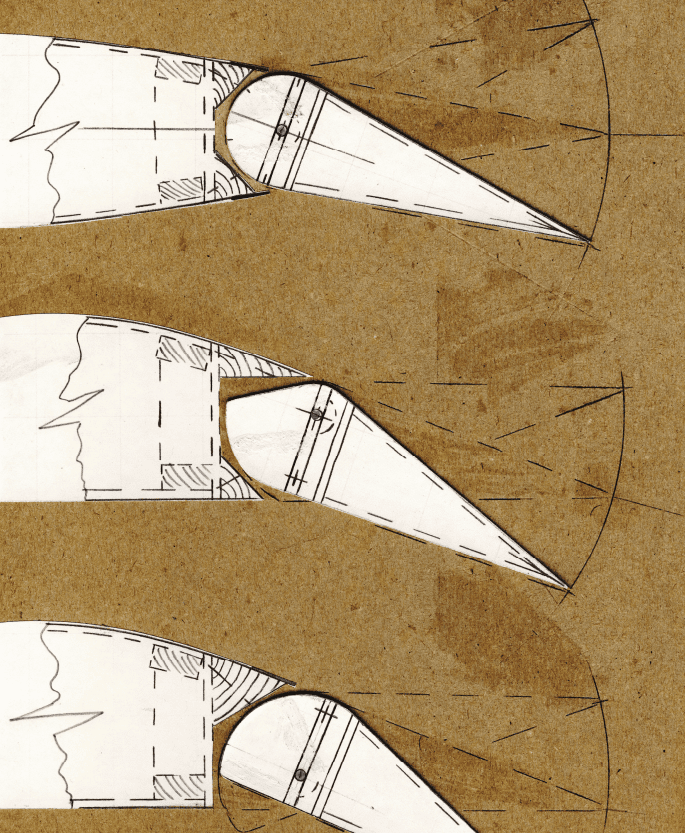

What are Bottom Hinged Aircraft Hinges?

Bottom hinged designs are found in ailerons, flaps, and accessory doors. Much like their counterparts, they are critical for controlling the aircraft’s movements. Bottom hinged designs allow for downward pivotal motion, making them suitable for ailerons and flaps, which often need to move in this direction.

These hinges are made robust to withstand high stress and pressure, especially during takeoff and landing. Also, like center and top-hinged designs, they employ the ‘hinge block’ design approach, which aids in their manufacture and maintenance.

Can you tell me about the Materials Used in Aircraft Hinges?

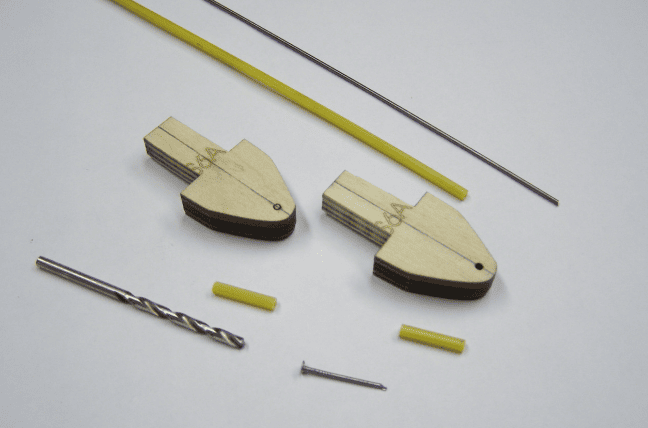

Aircraft hinges need to be extremely strong and durable to withstand the forces exerted on them during flight. That’s why materials like aircraft-grade plywood, NY-ROD for the bearing, and music wire for the hinge pin are often used in their construction.

The use of these materials ensures that the hinge will remain functional and safe throughout the life of the aircraft. And the beauty of this type of design is that if the bearing ever wears out, it can be replaced with little effort, even after the plane is painted.

How about the Durability and Maintenance of Aircraft Hinges?

Aircraft hinges are designed for longevity and minimal maintenance. The combination of robust materials and efficient design ensures these hinges can withstand years of use. However, like any other part of an aircraft, they require regular inspection and maintenance.

Hinges should be checked for wear and tear, and replaced if necessary. This is relatively easy due to the design of the hinges, as the bearing material can be replaced with minimal effort.

What is the Process of Installing Aircraft Hinges?

The process of installing aircraft hinges involves precision and technical knowledge. It begins with cutting the hinges to shape and drilling them for a press fit of the bearing material. The bearing is then installed and trimmed flush to both sides of the hinge.

This approach ensures a snug fit with no room for wobbling. Once installed, the hinge allows for the precise movement of the aircraft’s control surfaces, contributing to its overall performance and safety.

How do Aircraft Hinges Contribute to Flight Safety?

Aircraft hinges play a significant role in ensuring flight safety. Their efficient design and strategic placement allow for accurate control of the aircraft’s movements. A malfunctioning hinge can lead to loss of control, so their maintenance is essential for safe operation.

Moreover, the use of durable materials and efficient designs minimizes the risk of hinge failure, contributing further to flight safety.

Conclusion

In conclusion, aircraft hinges may seem like small, insignificant components, but their role in the safe and efficient operation of an aircraft cannot be overstated. From center-hinged to top and bottom-hinged designs, each type of hinge serves a unique function, contributing to the precision control of an aircraft. The materials used, their design, installation, and maintenance all come together to ensure these hinges stand the test of time and the harsh conditions of flight. So, next time you fly, remember that it’s not just the engines and the wings that make flight possible – it’s also the intricate world of aircraft hinges.

You might also be interested: