When it comes to industrial equipment, having hinges that can withstand heavy loads is essential for ensuring the stability, safety, and longevity of the equipment. In this blog post, we will discuss different types of hinges that excel in holding the significant weight in the field of industrial equipment, such as industrial precision ovens, environmental testing chambers, and constant temperature and humidity test chambers. We will focus exclusively on the industrial equipment domain, excluding any references to furniture, construction, or interior design.

Types of Hinges with High Weight Capacity for Industrial Equipment:

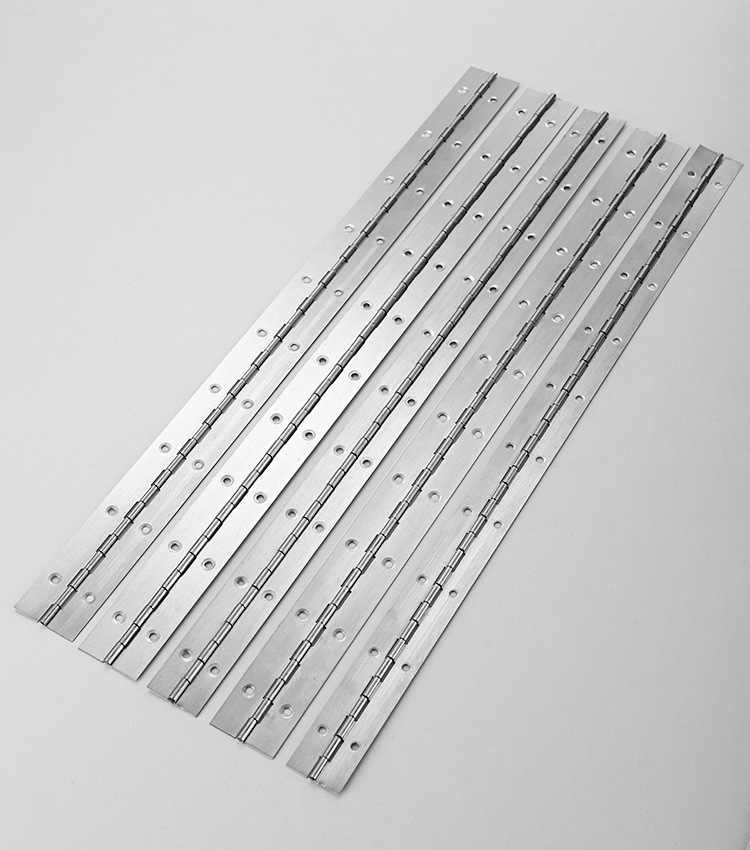

Continuous Hinges

Continuous hinges, also known as piano hinges, are renowned for their high weight-bearing capacity. These hinges run the full length of the door or panel, evenly distributing the weight and minimizing stress on the hinge. They are commonly made of durable materials such as stainless steel, allowing them to handle heavy loads while providing long-lasting performance in demanding industrial environments.

Heavy-Duty Butt Hinges

Heavy-duty butt hinges are specifically designed to support heavy doors or panels. They feature robust plates and pins that offer excellent load-bearing capabilities. These hinges are constructed to withstand substantial weight and provide reliable and secure operation in industrial equipment applications.

Bearing Hinges

Bearing hinges are an excellent choice for high weight capacity applications. These hinges incorporate bearings or bushings, reducing friction and facilitating smooth movement even under heavy loads. They ensure effortless operation while providing exceptional strength and stability for industrial equipment.

Industrial Pivot Hinges

Pivot hinges are another type of hinge suitable for handling significant weight. They are designed to support the rotational movement of heavy doors or panels around a fixed point. With proper design and construction, pivot hinges can handle substantial loads, making them ideal for industrial equipment applications.

Conclusion

When it comes to industrial equipment, selecting hinges with high weight capacity is crucial for ensuring optimal performance and safety. Continuous hinges, heavy-duty butt hinges, bearing hinges, and pivot hinges are among the top choices for handling significant weight. Factors such as durability, load-bearing capacity, and smooth operation should be considered when choosing the appropriate hinge for industrial equipment.

As a professional manufacturer specializing in heavy-duty industrial hinges, HINGES is dedicated to providing high-quality products and custom hinge solutions. With our expertise and experience in hinge customization, we can meet the specific requirements of our customers in the industrial equipment sector. Please feel free to contact us for further information or to discuss your custom hinge needs. We are committed to delivering top-notch products and excellent customer service.