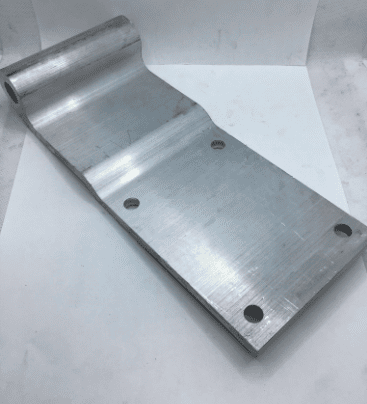

Trailers, being an integral part of the logistics and transportation sector, require components made with precision and quality. One such vital component, often overlooked, is the hinge of the trailer gate. It’s more than a simple joint; it’s the linchpin that ensures safety and functionality.

Aluminum trailer gate hinges offer a combination of strength, durability, and cost-effectiveness ideal for modern transportation needs. Their lightweight nature ensures reduced strain on structures, while their resistance to corrosion and adaptability in design makes them suitable for various conditions and requirements. The eco-friendliness of aluminum, due to its recyclability, further solidifies its position as a top choice in the industry.

Let’s dive deep into the characteristics that make aluminum an ideal choice for trailer hinges.

Lightweight Nature

Aluminum, known for its lightweight characteristics, offers significant advantages when used in the fabrication of trailer gate hinges. Reduced weight means that there’s less strain on the associated structures, which might enhance the overall lifespan of the trailer’s gate.

Moreover, the ease of handling lighter hinges also ensures a smoother installation process. This can translate to reduced labor efforts and potential cost savings in the installation phase.

Durability and Strength

Aluminum might be lightweight, but it’s remarkably sturdy. This metal possesses a commendable strength-to-weight ratio, meaning that even with less material usage, the hinge is both resilient and robust.

Such durability ensures that the trailer gate hinges can withstand substantial force, making them apt for heavy-duty operations. The result is a longer-lasting hinge that offers reliable performance.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to atmospheric conditions. This inherent trait provides it with a shield against corrosion, a crucial feature for trailer gate hinges.

Given that these hinges frequently encounter varying weather conditions and potentially corrosive agents like road salts, aluminum’s ability to resist corrosion ensures extended longevity and consistent performance.

Thermal and Electrical Conductivity

Thermal and electrical conductivity, while not directly influencing hinge function, play a role in the manufacturing process. Aluminum’s high conductivity levels ensure that heat is evenly distributed during processes like welding.

This even distribution of heat ensures uniformity in production, translating to consistent quality across batches and reduced chances of manufacturing defects.

Non-Magnetic Property

Modern trailers, often equipped with advanced electronic systems, require components that don’t interfere with these setups. Aluminum’s non-magnetic nature ensures that electromagnetic interference is kept at bay.

Thus, with aluminum hinges in place, trailer owners can be assured that their electronic systems, be it for tracking or other functionalities, will operate without hindrance.

Flexibility in Design

The malleability of aluminum is one of its standout features. This quality allows manufacturers to craft hinges tailored to specific requirements. Whether there’s a demand for a unique size, design, or mechanism, aluminum can be seamlessly shaped to fit the bill.

Such flexibility ensures that trailer owners aren’t restricted by design limitations and can opt for custom solutions that align perfectly with their needs.

Cost-Effectiveness

In the realm of metals, aluminum offers a balance between quality and cost. Its abundance and ease in manufacturing often lead to economical hinge options without any compromise on their performance or durability.

For trailer owners, this translates to quality hinges that don’t break the bank, ensuring value for money with each purchase.

Eco-Friendly Attributes

With the global emphasis on sustainability, aluminum’s recyclability becomes a significant asset. Once an aluminum trailer gate hinge has served its purpose, it can be recycled, thus promoting eco-friendly practices within the industry.

This not only reduces the environmental footprint but also reinforces the industry’s commitment to green practices and sustainable development.

Conclusion

Aluminum trailer gate hinges, with their blend of durability, design flexibility, and eco-friendliness, offer a comprehensive solution for modern trailers. As the industry evolves, aluminum, with its myriad of advantages, is poised to be at the forefront of trailer gate hinge innovations.

You might also be interested: