Choosing the right concealed hinge is critical for the performance and accessibility of industrial electrical cabinets.

To choose adjustable concealed hinges for electrical cabinets, consider key factors like cabinet size, hinge material, door weight, corrosion resistance, and opening angle. Choose hinges with multi-directional adjustment for easier installation and maintenance. Always verify compatibility with enclosure design and environmental requirements.

For durable, long-term enclosure performance, understanding the hinge type and its capabilities is essential.

What Are Adjustable Concealed Hinges for Electrical Cabinets?

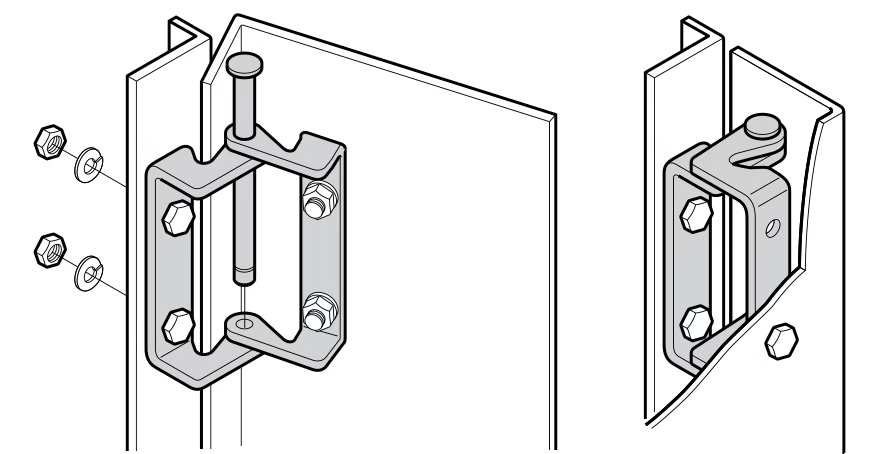

Adjustable concealed hinges are hidden mechanical components designed to connect cabinet doors to enclosures while remaining invisible when closed. Unlike traditional external hinges, they are embedded within the enclosure body and door frame, offering a sleek appearance and preventing unauthorized tampering. For electrical cabinets, especially in industrial settings, concealed hinges offer added protection against dust, moisture, and accidental access.

These hinges typically provide adjustability in three directions—vertical, horizontal, and depth—allowing for fine-tuning after installation. This is especially useful when the cabinet doors need to be perfectly aligned or readjusted during maintenance. Compared to standard butt hinges, adjustable concealed hinges offer a professional-grade solution that improves door stability and allows for easier realignment, reducing stress on the mounting hardware and frame.

Adjustable concealed hinges are internal hinges that offer multi-directional alignment and space-saving benefits in electrical cabinets, improving security, appearance, and maintenance access.

Key Factors to Consider When Choosing Adjustable Concealed Hinges

When selecting adjustable concealed hinges for your electrical cabinets, several core factors must be considered to ensure compatibility and long-term reliability. First, material plays a crucial role. Stainless steel is ideal for corrosive or high-humidity environments, while zinc alloy offers cost-effectiveness for less demanding applications. For outdoor industrial hinges, look for electro-galvanized or hot-dipped finishes to protect against rust and wear.

Next is load capacity—match the hinge to the cabinet door’s weight. Heavy panels require heavy duty hinges or even reinforced options like heavy-duty long hinges for oversized access panels. Adjustability should include all three axes for optimal door fit. Also, factor in the opening angle; applications that need full access will benefit from wide-throw hinges that can open to 180° or more.

Consider hinge material, load rating, adjustability, and opening angle when choosing concealed hinges for electrical cabinets. Match hinge type with door weight and environmental exposure.

Types of Concealed Hinges Used in Electrical Enclosures

Several types of concealed hinges are commonly used in industrial enclosures, each with its strengths. Lift-off concealed hinges allow for quick removal of cabinet doors without unscrewing—ideal for environments where frequent internal access is required. These are especially useful for testing equipment or maintenance-heavy installations.

Another type is the adjustable torque stainless steel hinge, which adds resistance to the door movement, holding it open or closed at set positions without additional hardware. For permanent cabinet setups, weld on hinges can be concealed within the enclosure structure, providing strength and durability for heavy-duty doors.

Lift-off, adjustable torque, and weld-on concealed hinges serve different purposes in enclosure applications. Choose based on access frequency, weight, and required adjustability.

Common Challenges and Mistakes in Hinge Selection

One common mistake is underestimating the required adjustability. Without multi-axis adjustment, installation becomes labor-intensive, and even slight misalignments can compromise sealing and access. Adjustable concealed hinges solve this problem by allowing post-installation fine-tuning—particularly important for electrical enclosures with gasketed or sealed doors.

Another issue is the mismatch between hinge load capacity and the actual door weight. Using hinges rated below the needed load can result in sagging doors or even hinge failure. In environments with vibration or external forces—such as vehicles or outdoor cabinets—heavy duty exterior hinges or friction hinges in industrial applications should be considered to maintain positioning and stability.

Selecting the wrong hinge type or underestimating weight/load capacity can lead to misalignment, sealing failure, or hinge fatigue. Always match hinge specifications to application demands.

Recommended Scenarios for Adjustable Concealed Hinges

Adjustable concealed hinges are ideally suited for sheet metal electrical enclosures, control cabinets, and testing chambers where clean aesthetics and secure enclosures are critical. For mobile or vibration-prone applications like industrial trucks or construction panels, consider using a heavy duty truck door hinge with concealed installation to reduce tampering and wear.

In high-end or large-panel cabinet builds, engineers often replace industrial door hinges with concealed styles for better protection and minimal space impact. In cases where doors need to be removed for servicing, take-apart hinges with hidden mounts are a great option. For cold or humid environments, integrating cold storage room hinges with concealed adjustable features ensures sealing performance isn’t compromised.

Applications like control panels, test chambers, and truck enclosures benefit from adjustable concealed hinges for better door alignment, tamper resistance, and space efficiency.

Conclusion

Adjustable concealed hinges enhance cabinet design, installation precision, and long-term usability. Choosing the right hinge ensures performance, safety, and maintenance convenience in industrial settings.