Choosing the right heavy duty exterior door hinges for industrial environments ensures reliability, longevity, and smooth door operation even under extreme conditions.

To choose the right heavy duty exterior door hinges for harsh environments, focus on corrosion resistance, load capacity, and hinge type. Materials such as 316 stainless steel or electro-galvanized finishes provide superior durability in corrosive or outdoor settings.

Industrial buyers should evaluate both performance and maintenance requirements before finalizing hinge specifications.

Understand the Environmental Challenges First

Harsh environments present unique challenges that directly affect hinge performance, especially for outdoor or industrial enclosures. High humidity, corrosive chemicals, and abrasive particles can accelerate wear and rust formation. These conditions demand heavy duty exterior hinges designed with superior weatherproofing and sealing technology.

Environmental stress factors like moisture, salt, and frequent use can degrade hinge efficiency. Selecting corrosion-resistant hinges ensures long-term functionality and stability in industrial environments.

Corrosion resistance is especially vital in marine and chemical processing applications. High humidity combined with frequent door movements can damage untreated metal surfaces. Temperature fluctuations also cause expansion and contraction, reducing hinge accuracy. Using 316 Stainless Marine Friction Hinges can effectively resist rust and maintain performance even under salt exposure.

Temperature extremes in test chambers, outdoor electrical panels, or industrial ovens can weaken standard hinges. In such cases, engineers should consider materials like 304 or 316 stainless steel with reinforced pivot points for long-term endurance.

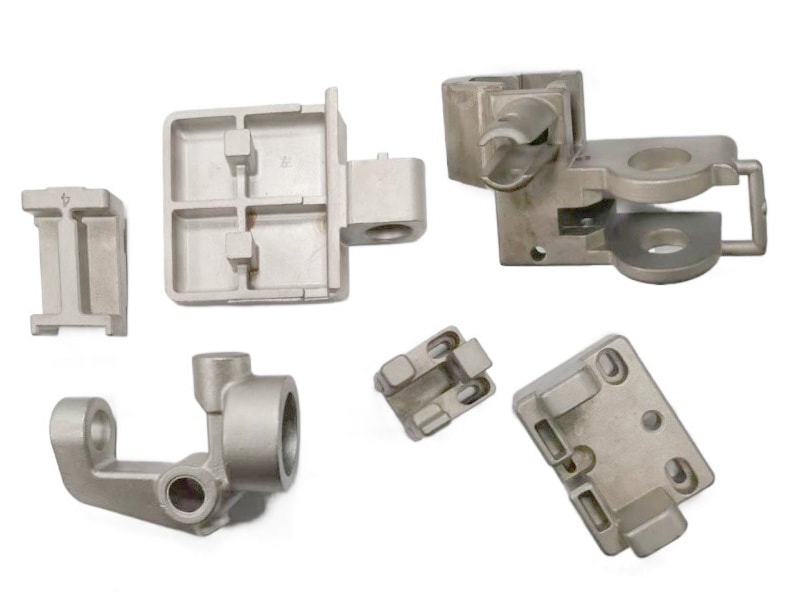

Choose the Right Hinge Material

Material selection determines both strength and corrosion resistance. Stainless steel remains the most recommended choice for harsh outdoor environments, offering superior resistance to rust and chemical reactions.

In extreme industrial conditions, 316 stainless steel provides unmatched corrosion resistance, while aluminum and carbon steel offer cost-effective alternatives for less aggressive settings.

| Material Type | Corrosion Resistance | Strength | Cost Level | Ideal Application |

|---|---|---|---|---|

| 316 Stainless Steel | Excellent | High | $$$ | Marine, Outdoor, Chemical Plants |

| Aluminum | Good | Medium | $$ | Lightweight Industrial Doors |

| Carbon Steel | Moderate | Very High | $ | Indoor, Low-Moisture Environments |

For cost-sensitive operations, Electro-Galvanized and Hot-Dipped Hinges are effective options, as the coating provides a protective barrier against oxidation. Aluminum hinges, while lighter, are ideal for enclosures requiring frequent movement but minimal exposure to corrosive substances.

Consider Load Capacity and Door Weight

Industrial door systems vary widely in size and weight. A hinge’s load capacity should always exceed the door’s operational weight to prevent sagging or misalignment.

Heavier doors demand reinforced hinge structures, thicker leaves, and higher axial strength to maintain consistent movement without deformation.

The total load must be distributed across multiple hinges. For example, large industrial enclosures may require three or four hinges to ensure stability during high-frequency operation. High-traffic areas also benefit from Heavy Duty Continuous Hinges, which distribute the weight evenly along the full door length, minimizing stress at pivot points.

Dynamic loads caused by vibration or air pressure fluctuations further increase hinge fatigue. Engineers must verify torque and pivot pin strength when specifying hinges for heavy or frequently accessed panels.

Select the Appropriate Hinge Type

Hinge type affects installation, function, and maintenance efficiency. The most common industrial options include weld-on, continuous, detachable, and butt hinges.

Different industrial applications demand different hinge types—continuous hinges for full-length support, weld-on hinges for permanent steel doors, and detachable hinges for quick removal.

Weld-on hinges in industrial applications are preferred for steel fabrication because they offer exceptional rigidity and alignment accuracy. They eliminate screw loosening issues caused by vibration, making them ideal for outdoor machinery or transport containers.

Detachable or lift-off designs allow easier maintenance, especially when frequent access to internal components is required. Continuous or “piano” hinges, on the other hand, deliver even stress distribution across the entire door surface, extending service life and reducing warping risks.

| Hinge Type | Key Benefit | Suitable Use |

|---|---|---|

| Weld-on Hinges | Permanent, high-strength joints | Steel Equipment Doors |

| Continuous Hinges | Uniform load distribution | Heavy Access Panels |

| Detachable Hinges | Easy door removal | Maintenance Access Panels |

Evaluate Finish and Coating Options

Surface finishing significantly extends hinge lifespan by preventing corrosion, rust, and wear. Industrial-grade coatings can transform standard hinges into long-term assets for harsh applications.

Protective finishes like powder coating, zinc plating, or hot-dip galvanizing provide resistance to corrosion, moisture, and mechanical abrasion.

Electroplated zinc finishes deliver cost-effective corrosion protection, while powder coatings add chemical resistance and aesthetic uniformity. In coastal or marine settings, hot-dip galvanization forms a dense protective layer that performs well under prolonged salt exposure.

Choosing the proper coating depends on environmental exposure and maintenance availability. For example, heavy salt conditions require dual-layer protection: base metal plating and an external coating.

Maintenance and Lifecycle Costs

Choosing the right hinge also involves balancing initial investment with long-term maintenance costs.

Low-maintenance or self-lubricating hinges reduce downtime, improve reliability, and lower total ownership costs in heavy-use industrial applications.

For facilities with limited access or where manual lubrication is impractical, maintenance-free hinges with built-in bearings are ideal. They eliminate friction-related wear, extending the hinge’s operational lifespan. Regular inspections, cleaning, and torque checks should be scheduled to prevent unexpected failures.

Additionally, selecting quality hinges from the start minimizes replacement frequency. Engineers should calculate lifecycle cost rather than focusing only on upfront pricing. In most cases, a higher-grade hinge pays off through reduced maintenance and longer service intervals.

Conclusion

To select the right heavy duty exterior door hinges for harsh environments, consider environmental exposure, material selection, hinge type, and maintenance requirements. The right hinge ensures long-term durability, operational stability, and total cost efficiency in demanding industrial applications.