316 stainless marine friction hinges are essential for ensuring stability, durability, and corrosion resistance in demanding marine environments.

To choose the best 316 stainless marine friction hinges, focus on corrosion resistance, torque control, installation type, and intended application. These hinges must withstand saltwater, UV exposure, and constant movement. Heavy-duty construction, proper torque rating, and reliable mounting methods are critical for boat and yacht functionality.

Read on to understand what makes a marine hinge truly reliable under real-world industrial demands.

What Makes 316 Stainless Steel Ideal for Marine Friction Hinges?

316 stainless steel is widely regarded as the best material for marine-grade friction hinges due to its superior resistance to corrosion. Unlike 304 stainless steel, 316 includes molybdenum—an element that significantly increases its resistance to salt spray, chlorides, and acidic environments, which are common in marine operations.

This enhanced corrosion resistance makes 316 stainless marine hinges ideal for long-term use on yachts, fishing vessels, and other marine craft. In contrast, 304 hinges may corrode faster when exposed to seawater, reducing structural integrity and requiring frequent replacements. By investing in 316-grade materials, industrial boat and yacht manufacturers can extend product life cycles and reduce maintenance needs.

316 stainless steel hinges are better than 304 in marine environments because they resist chloride corrosion and provide longer-lasting performance under saltwater exposure.

How Do Marine Friction Hinges Work in Industrial Applications?

Friction hinges function by providing resistance throughout the range of motion without the need for additional mechanical stays. They utilize controlled torque to keep doors, hatches, or panels in place at any angle—especially crucial in turbulent marine environments where safety and convenience matter most.

In industrial marine applications, friction hinges support equipment panels, engine room doors, and access hatches that must remain open or closed without slamming or drifting due to movement or wind. This makes them essential in shipbuilding, control systems, and marine engineering where vibration and water exposure are constants.

Marine friction hinges use internal torque to hold doors or hatches at any position, providing stability without mechanical stays in marine equipment.

Key Factors to Consider When Choosing Marine Friction Hinges

When selecting the right friction hinge for marine use, the first consideration should be corrosion resistance—only 316 stainless or marine-grade materials will endure long-term exposure to seawater. Next, assess the torque requirement. Over-torqued hinges may be difficult to move, while under-torqued hinges can’t hold position. Manufacturers often provide torque specifications based on panel size and weight.

Mounting method is another key factor. For boats, weld on hinges offer high-strength permanent installation, while adjustable friction hinges allow fine-tuning in field conditions. Also consider exposure: for exterior doors or equipment panels, heavy duty exterior hinges made from 316 stainless with sealed joints are ideal for weatherproofing.

Choose marine friction hinges by evaluating corrosion resistance, torque specifications, installation method, and environmental exposure. 316 stainless steel and adjustable torque designs offer the best durability.

Common Types of Marine Friction Hinges and Their Use Cases

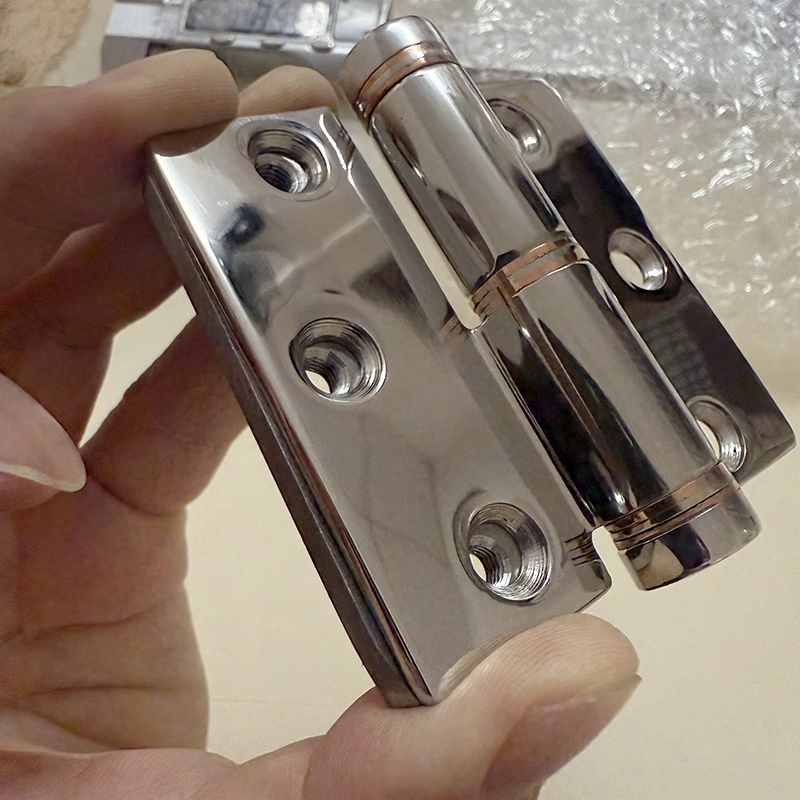

Marine friction hinges come in various designs suited to specific parts of a boat or industrial vessel. For instance, Take-Apart Hinges are often used in removable panels for easy maintenance. Heavy-duty long hinges support extended hatches or wide doors subjected to high stress. In compact spaces, concealed friction hinges maintain a clean design and reduce snag points.

Applications vary widely: engine compartments use sealed heavy-duty hinges; control panels rely on electrical panel hinges with precision control; cold storage rooms on fishing vessels may need cold storage room hinges built for temperature fluctuations. Selecting the right type ensures optimal performance, especially when integrated into custom marine designs.

Marine friction hinges include take-apart, long-format, concealed, and heavy-duty variants, each tailored for engine rooms, control panels, or access doors in marine vessels.

Comparing Brands and Custom Manufacturing Options for OEM Buyers

While large marine brands like Gemlux and Taco Marine offer ready-made solutions, OEM buyers often require customization to meet unique design specs. Off-the-shelf products may lack the torque tuning, mounting pattern, or corrosion-grade customization industrial clients need. This is where working with a direct manufacturer like IHINGES becomes a strategic advantage.

At IHINGES, we provide custom special hinges, detailed 3D models, and can laser-engrave logos for brand identity. Our production lines support low MOQ and full OEM development, ideal for buyers needing unique solutions such as Replace Industrial Door Hinges or Heavy Duty Truck Door Hinges. For importers and resellers in the U.S. and Europe, this enables competitive branding with factory-direct quality assurance.

OEM buyers benefit from custom hinge production with torque calibration, corrosion-resistant materials, and logo branding by working with a direct manufacturer like IHINGES.

Conclusion

Choosing the right 316 stainless marine friction hinge ensures lasting performance, safety, and efficiency in boat and yacht applications. Match materials, torque, and type to your use case for optimal results.