Choosing the right heavy-duty long hinges ensures stability, durability, and precision in industrial equipment operation.

To choose the right heavy-duty long hinges, consider your equipment’s weight, operating frequency, environmental exposure, and mounting configuration. Evaluate material types like stainless steel or aluminum for durability, and ensure hinge length and cycle life match your application needs. Customization, certifications, and installation methods are also critical. Matching the hinge specifications with actual usage conditions is key to long-term industrial performance.

Here’s how to select the ideal hinge for your equipment, step by step.

Understand Your Equipment’s Load and Usage Requirements

Every industrial hinge must support a specific load. This includes the static weight of the panel or door, dynamic stress from repeated motion, and additional forces from vibration or impact. Failing to account for these forces can lead to premature wear or mechanical failure. Choose hinges based on the total load they must support and how frequently the equipment operates. Overloading or under-specifying leads to failure.

For example, heavy-duty long hinges used in test chambers or outdoor enclosures must not only bear significant weight but also withstand high usage cycles. It’s critical to match the hinge rating with real-world demands. One helpful method is the 2/3 rule, which suggests using two hinges for lighter panels and adding a third for longer or heavier doors.

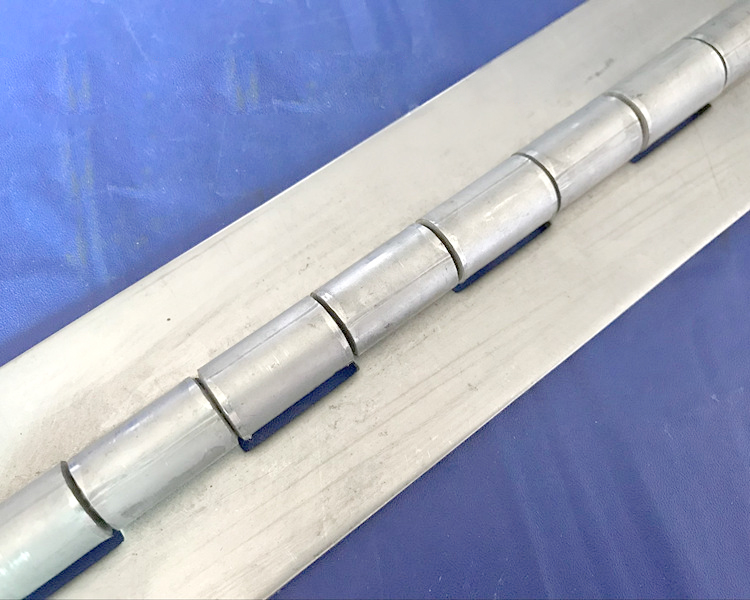

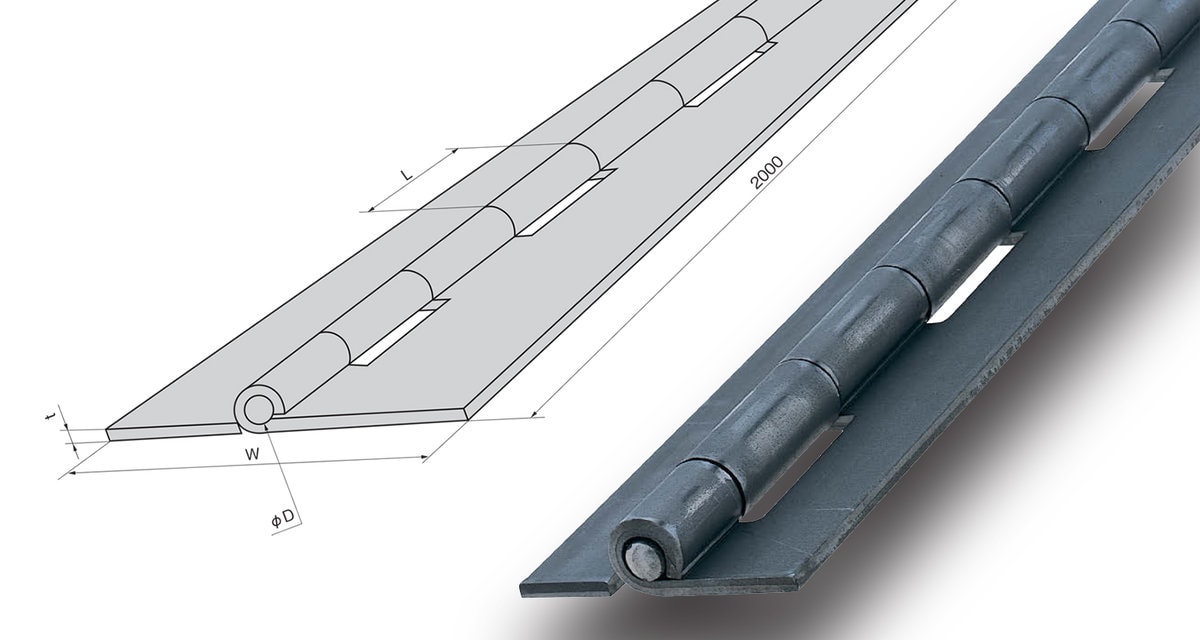

In high-cycle environments, such as climate test chambers or cold storage units, opting for heavy duty hinges with proven endurance ratings ensures consistent performance and safety. If you’re dealing with doors that weigh hundreds of pounds or require long, uninterrupted support, consider piano hinges for continuous load distribution.

Choose the Right Hinge Type for Industrial Applications

Industrial hinges aren’t one-size-fits-all. Depending on your use case, you might need standard butt hinges, concealed types, or specialized variants such as heavy-duty long hinges that offer extra surface engagement across wide panels. Heavy-duty long hinges are ideal for large panels, enclosures, or industrial doors requiring extended support across long lengths.

These hinges are especially effective for electrical cabinets, machinery housings, and test equipment doors where precision and even weight distribution are critical. For instance, if you’re looking to Replace Industrial Door Hinges that have failed due to side loading or misalignment, long hinges offer superior mechanical advantage and reduce torsion stress.

If your application requires frequent removal or access for maintenance, Take-Apart Hinges or Detachable Hinges are ideal. In harsh environments, outdoor industrial hinges with corrosion-resistant finishes are preferred. It’s important to select not just the hinge size, but the hinge type that best fits your operational requirements.

Match Material and Finish to the Environment

Industrial environments vary widely — from moisture-rich food processing plants to high-heat testing chambers. The material and surface treatment of your hinges should align with the application’s surroundings to prevent corrosion, deformation, or reduced lifespan. Use stainless steel for corrosion resistance, aluminum for weight-sensitive applications, and powder-coated steel for general indoor use.

For example, Aluminum Geared Continuous Hinges are perfect for lightweight panels that still require continuous support, particularly in equipment where weight reduction is crucial. On the other hand, Electro-Galvanized and Hot-Dipped Hinges are ideal for outdoor or chemical-rich environments where oxidation is a concern.

In industries like food processing or marine applications, stainless steel is non-negotiable. And if you need a hinge that provides resistance to chemicals or extreme temperatures, make sure the finish can handle it. Selecting the wrong material often leads to rust, hinge binding, or even complete failure in less than a year.

Consider Mounting Style and Hinge Installation

Your mounting method directly impacts hinge performance and ease of maintenance. Whether you weld, bolt, or screw-mount the hinge affects how weight and force are distributed across the equipment. Weld-on hinges offer maximum strength, while bolt-on options allow for easier replacement and maintenance in industrial settings.

For structural doors or machinery housings, weld on hinges are widely used because they integrate directly into the frame and support heavy vertical loads. They’re ideal for permanent installations that require rugged performance. In contrast, bolt-on or screw-mount hinges allow for adjustments, ideal in environments where parts must be periodically replaced or aligned.

Mounting alignment is also critical. Incorrectly aligned hinges can lead to binding, premature wear, or structural damage to both the hinge and the equipment. Always confirm the mounting holes are precisely measured, and consider jigs or laser alignment tools for accuracy.

Evaluate Cycle Life, Safety Standards & Customization Options

Cycle life refers to how many times a hinge can operate before failing. For industrial applications, this can range from thousands to millions of cycles. It’s essential to choose a hinge with a certified cycle rating suitable for your application’s usage frequency. Ensure hinges meet your desired cycle life, comply with industry standards, and support custom features like logo, length, or special coatings.

For example, if your equipment opens 500 times a day, a hinge rated for only 50,000 cycles may wear out in months. Look for data-backed ratings. Some customers also request special hinges with unique lengths, mounting holes, or surface treatments to match specific equipment designs or branding requirements.

Safety and compliance are also critical. Hinges used in electrical cabinets or lab testing chambers may need UL or ISO certification to meet regional standards. In such cases, working with a hinge manufacturer like IHINGES ensures access to engineering drawings, CAD files, and customized solutions designed specifically for B2B industrial clients.

Conclusion

Choosing the right heavy-duty long hinges isn’t just about size—it’s about matching technical needs with material, type, and function. With IHINGES, you get precision-built, customizable solutions tailored to industrial environments.