Choosing the right mechanically fastened hinges for any project is crucial as they play a significant role in the functionality and longevity of doors, gates, and other pivoting structures. The right hinge not only ensures smooth operation but also affects the durability and security of the installation.

Understanding the specific needs of your project and the demands placed on the hinges is vital. Selecting the appropriate hinge involves considering factors like load capacity, environmental conditions, and the material of the components being joined.

Maintaining these considerations will guide you through selecting the best mechanically fastened hinges for your needs.

Understand the Basics of Mechanically Fastened Hinges

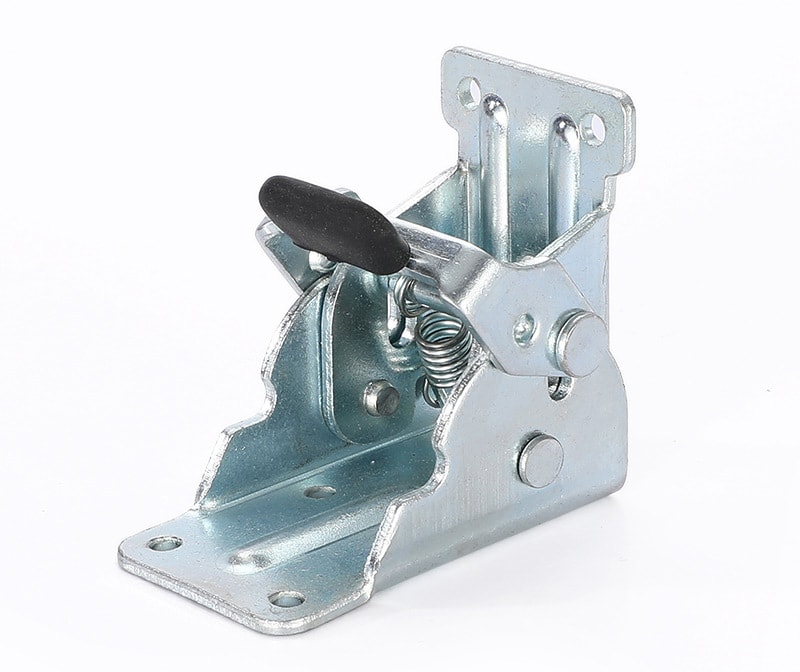

Mechanically fastened hinges are a popular choice for many construction and manufacturing projects due to their reliability and strength. These hinges are typically attached with screws, bolts, or other mechanical fasteners, making them adjustable and more secure than their welded counterparts.

When considering mechanically fastened hinges, it’s important to understand the basic types available: butt hinges, continuous hinges, and specialty hinges like piano or T-hinges. Each type serves different purposes and comes with its own set of advantages and installation considerations. For example, butt hinges are commonly used for doors, while continuous hinges are ideal for providing support over a longer length, such as on storage boxes or lids.

Evaluate the Material Requirements

The choice of material for your hinges is critical and should align with the environment in which the hinge will operate. Common materials include steel, stainless steel, brass, and aluminum, each offering different benefits in terms of strength, corrosion resistance, and aesthetic appeal.

For instance, stainless steel hinges are best for corrosive environments such as coastal areas or chemical exposure areas because of their rust-resistant properties. On the other hand, brass hinges are often chosen for their visual appeal in decorative applications. Selecting the right material ensures that the hinge will perform well under the expected conditions and have a longer lifespan.

Consider Load Capacity and Usage Frequency

The load capacity and frequency of use are crucial factors when selecting hinges. Heavy-duty hinges are necessary for doors or panels that bear a lot of weight or are used frequently. These hinges are designed to withstand greater forces and repeated use without failing.

It’s essential to calculate the expected load and consider the level of usage to choose a hinge that can handle the stress without deforming or breaking. For high-traffic areas, such as public buildings or busy residential entryways, choosing a hinge that is built to tolerate frequent operations is a must to avoid maintenance issues and ensure safety.

Assess Installation and Maintenance Requirements

Ease of installation and future maintenance are important considerations when choosing mechanically fastened hinges. Some hinges come with features that simplify installation, such as slotted holes for minor adjustments or pre-drilled holes that match standard templates.

Maintenance aspects to consider include the ease of lubrication and the ability to tighten or replace fasteners. Hinges that are easier to maintain tend to last longer and perform better, especially in environments where wear and tear are more intense.

Explore Security Features

For projects where security is a concern, the hinge design can play a pivotal role. Features like non-removable pins or tamper-proof screws can enhance the security level of the installation. These features prevent the hinges from being easily compromised by removing the pin or unscrewing the hinge from the outside.

In high-security areas, such as entry doors to commercial buildings or access panels in sensitive environments, selecting hinges with enhanced security features is crucial for protecting against unauthorized access or vandalism.

Conclusion

Selecting the right mechanically fastened hinges involves careful consideration of the hinge’s type, material, load capacity, installation ease, maintenance needs, and security features. By understanding these elements, you can choose hinges that not only meet the functional requirements of your project but also contribute to its overall success and longevity.

You may be interested:

- What Are the Hidden Benefits of Installing Maintenance Free Door Hinges?

- Top 8 Things You Should Know About Lift Off Hinges

- Top 10 Things You Need to Know About Letter Box Hinges

- How to Find Alternatives to the Original Brand in China for Industrial Parts?