Achieving precise pin hole alignment in stamped hinge leaves is crucial for hinge functionality and durability in industrial use.

To ensure perfect alignment of hinge leaf pin holes, manufacturers must account for material springback, stamping deformation, and hole size tolerances. Especially after rolling or forming, the hole shape may distort, requiring additional grinding or clearance design to guarantee smooth assembly and rotation between hinge parts.

Continue reading to learn how professional engineers manage stamping accuracy and material selection to avoid costly alignment issues.

What Is a Stamped Industrial Hinge?

Stamped industrial hinges are fabricated by using precision stamping dies to form flat metal sheets into hinge components. This method is ideal for mass production, offering high consistency and repeatability. In the case of cold storage room hinges or heavy duty hinges, stamping allows for tight tolerances and structural strength at scale.

These hinges are widely used in industries requiring robust mechanical support, such as electrical enclosures, test chambers, or transportation equipment. The stamping process also allows for integrating features like countersinks or offset bends, saving on secondary operations and reducing production time. However, this manufacturing method requires extremely precise die design and material selection to ensure hole alignment and long-term performance.

Stamped industrial hinges are produced by pressing metal sheets using specialized dies, ensuring consistent shapes and hole locations ideal for high-volume production. This method is critical for applications where hinge rotation and strength are essential.

How Does Material Type Affect Stamping Results?

The material you choose for the hinge drastically affects the outcome of the stamping process. Mild steel, for example, is soft and ductile, making it easier to form and more predictable during stamping. Its minimal springback ensures that the hinge leaf’s pin holes retain their intended position and diameter after shaping. This makes it suitable for heavy-duty long hinges used in rugged environments.

Stainless steel, such as 316 Stainless used in 316 Stainless Marine Friction Hinges, poses a greater challenge. Its elasticity causes it to spring back after forming, which can distort the hole positioning or size. As a result, stainless steel hinges often require additional shaping or post-processing (such as flattening or precision grinding) to correct misalignments introduced during stamping or rolling. This additional step adds complexity and cost but is necessary for critical alignment.

Steel materials are easier to stamp with minimal deformation, while stainless steel often springs back, requiring secondary processing to maintain hole alignment. Choosing the right material based on application demands is vital for precision manufacturing.

How to Ensure Perfect Hinge Leaf Pin Hole Matching?

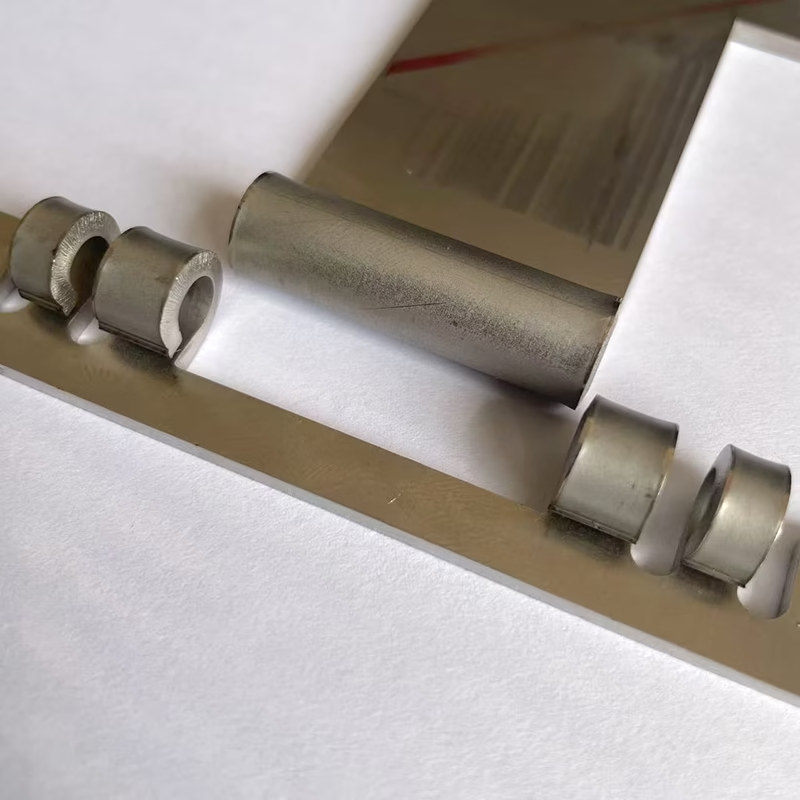

Ensuring the pin holes of two hinge leaves match perfectly requires careful design and manufacturing processes. During the hinge-making process, particularly after the rolling stage, the material around the pin hole often bulges or distorts slightly. This deformation is especially common in stainless steel, which tends to spring back. This protrusion must either be accounted for in the mold design or removed via grinding.

For industrial hinges like adjustable concealed hinges, it’s essential to either pre-compensate for the expected deformation or apply a post-processing technique that ensures the rolled edge won’t obstruct the mating hinge. Engineers usually allow a clearance zone around the pin hole or set different tolerance levels for the inner and outer hinge leaves. This step prevents the two parts from locking up due to tight or misaligned fits.

To ensure proper matching, the bulging area formed during rolling must be managed through mold compensation or precision grinding, especially for materials like stainless steel.

Accurate alignment avoids interference during rotation and guarantees smooth mechanical performance, especially in rotational-use hinges like friction hinges in industrial applications.

Why Are Pin Hole Sizes Different on Mating Hinge Leaves?

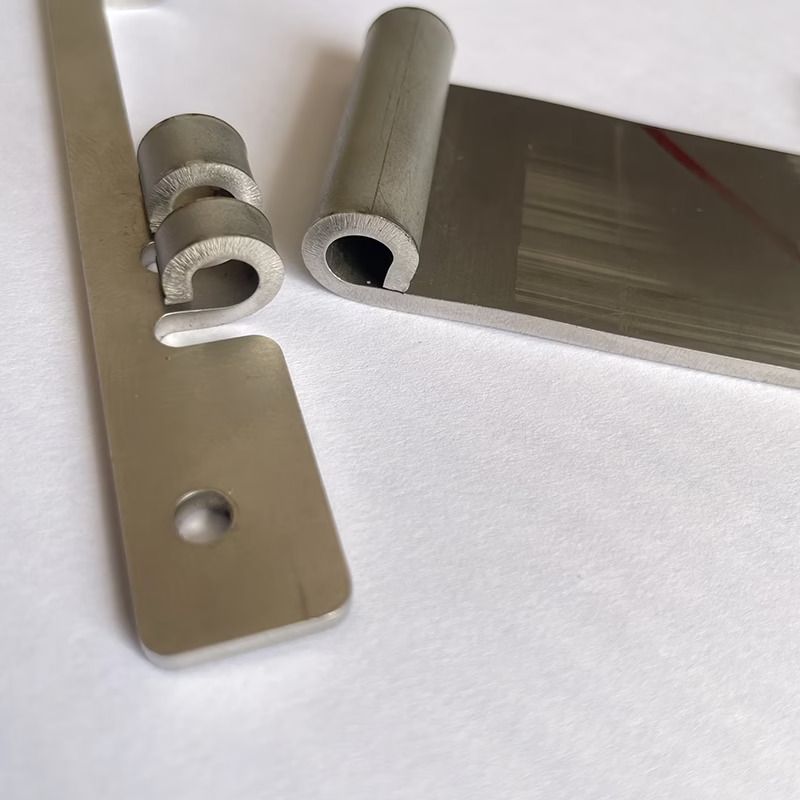

A critical design detail in industrial hinge engineering is intentionally creating different hole diameters in the two mating hinge leaves. Typically, one hinge leaf (e.g., leaf A) features a hole that tightly grips the hinge pin. The other leaf (leaf B) includes a slightly looser hole to allow rotational freedom. This approach ensures that while one side holds the pin firmly in place, the other can pivot smoothly without resistance.

For example, in a Take-Apart Hinge, the tight fit on one side allows the pin to stay stationary, while the loose fit on the other side enables easy disassembly and reassembly. This design is vital for equipment requiring frequent maintenance or panel access. The same logic applies to heavy-duty applications like electrical enclosures or heavy duty truck door hinges, where precision and function must coexist.

Hinge leaves often have different hole sizes—one for a tight fit and one for a loose fit—to ensure both secure fixation and smooth rotation. This balance is essential for functional and serviceable hinge systems.

Engineering Tips for Precision in Hinge Design

From the perspective of a stamping die engineer, several key strategies ensure accurate pin hole alignment:

-

Mold Tolerance Planning: During die design, include compensation for material stretch, springback, and hole displacement. Properly dimensioned pilot holes and guiding features reduce error.

-

Predictive Modeling: Use 3D CAD and forming simulation software to predict hole distortion during rolling or bending. This helps pre-compensate die cuts or bending angles.

-

Material Thickness Control: Ensure consistent sheet thickness; variations can cause non-uniform forming and alter pin hole positions.

-

Post-Processing Setup: For high-precision applications like butt hinges for doors, grinding or shaping stations may be added after stamping to refine hole edges or adjust for bulging.

-

Prototyping and Test Fitting: Always run test samples to assess tolerance stacking and actual fit between hinge halves before mass production begins.

Precision hinge production requires predictive modeling, tolerance planning, and in some cases, post-processing to meet strict pin hole alignment demands. These practices reduce failure rates and enhance end-product functionality.

Conclusion

Ensuring hinge leaf pin hole alignment demands careful material selection, stamping design, and engineering foresight. Every detail—from mold to post-processing—matters.