Among the many types of hinges, there is one type of hinge that is relatively long. Usually, the length is much longer than the width of the hinge. This type of hinge is called heavy-duty piano hinges, and how do you stiffen a piano hinge? So this is the name that has been used since then.

In this article, I will focus on how to install heavy-duty piano hinges. Also, other issues related to it are covered.

What are heavy-duty piano hinges?

This is a special type of industrial hinge. It is much longer than its unfolded width. These hinges are more widely used in industrial production. Of course, they are also used in the construction and furniture industry. We call it heavy-duty piano hinges home depot.

It consists of two long hinge blocks and a long pin. The pin connects the two hinge blocks together and remains fixed to one of the hinge blocks. This allows the two hinge blocks to rotate between each other.

What are the characteristics of heavy-duty piano hinges?

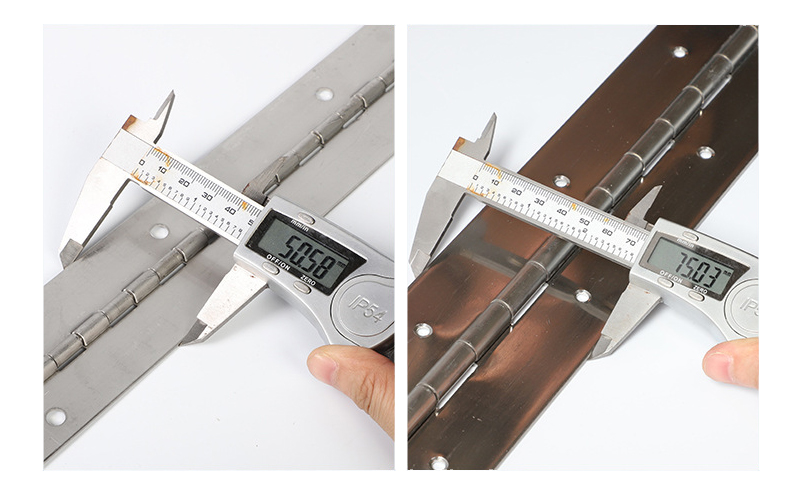

Its characteristics, we can introduce it in terms of its structural features and functional features. Its structure is similar to a long steel belt, which has a long or short length. The short one may be only 2 inches, which we call 2 inch heavy-duty piano hinge, and the long one may be very long, such as 24 inch heavy-duty piano hinge, or even longer. That is, its length is much longer than the width of the hinge block spread.

Functionally, it holds the door to the frame very firmly and allows a very stable rotation. Since it is continuously fastened to the door and frame and screwed at regular intervals, it is a very solid installation. This structure makes heavy-duty piano hinge weight capacity very strong.

What are the uses of piano hinges?

Heavy-duty continuous hinges are used primarily in commercial and industrial environments and in applications where they are in constant use. Examples include revolving doors in commercial kitchens, warehousing, manufacturing, and heavy furniture covers such as desks and large boxes.

Heavy-duty piano hinges are used primarily in both sets of commercial and industrial applications. There are also areas that we have not yet discovered that may be in heavy use. Heavy-duty piano hinge for trailer ramp, for example, is also used for doors in commercial kitchens and industrial special test equipment. There are also large storage doors, which we call heavy-duty piano hinge for gate, and outdoor doors, which we call heavy-duty outdoor piano hinge.

How to install heavy-duty piano hinges

The installation of heavy-duty piano hinges is different from the installation of normal heavy-duty hinges. It is possible that we will need at least two or more people to assist with the installation. This is because the length of heavy piano hinges is too long for one person to complete.

First, we need to align the door with the door frame and keep them level and in line with each other. At this point rotate the hinges on the door and door frame, marking the location of the first and last holes. Once you are sure the positions are correct, drill the remaining holes and tighten the screws.

After installation is complete, be sure to check for any rattles or doors that do not close tightly. Otherwise, the hinges may need to be adjusted.

How to choose the right piano hinges

They are available in many sizes, including 2 inch heavy-duty piano hinge, 3 inch heavy-duty piano hinge, 4 inch heavy-duty piano hinge and 24 inch heavy-duty piano hinge. in addition to these sizes, we customize heavy-duty piano hinges more according to the customer’s door size. This is because in general, the hinge length is as long as the door length. Different equipment door lengths require different lengths of heavy-duty piano hinge.

There are also different ways to match the hinge blocks to each other. Below I will detail the different ways of connecting the hinge blocks to each other.

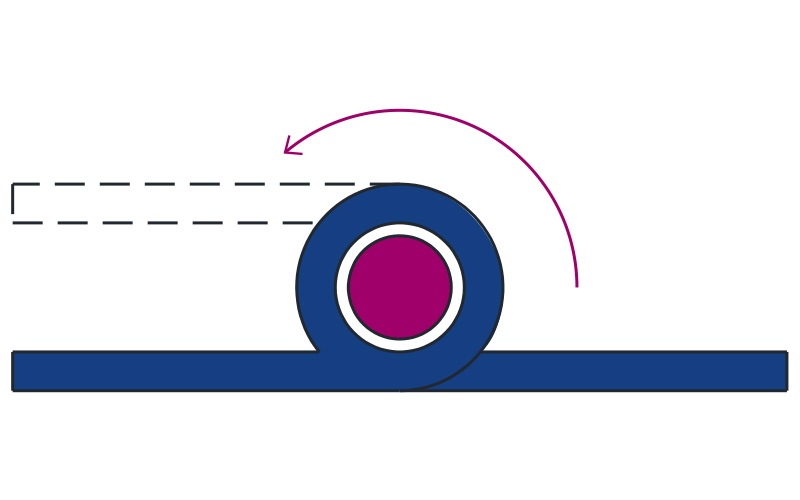

- Common type or standard typeThis is the most common and most frequently used form, which is two hinge blocks in the unfolded and flat state that are on the same horizontal plane. It is shown in the figure below.

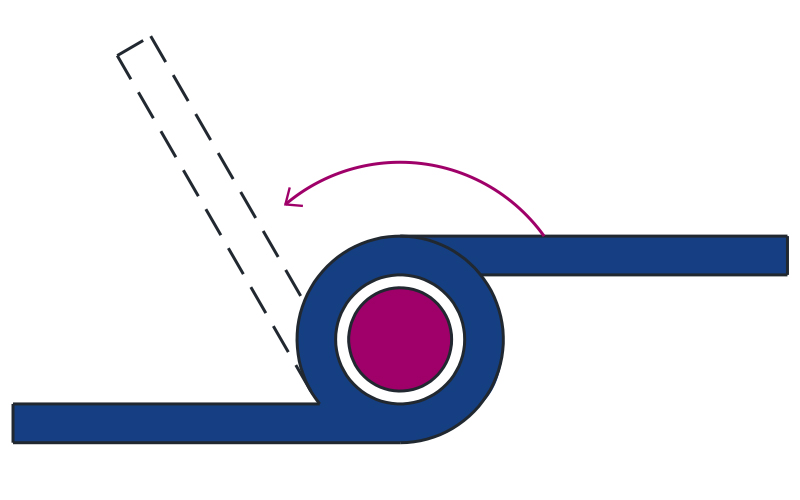

- Reverse assembly typeThis is the case where the two hinge blocks are reversed and opposed. They cannot be unfolded horizontally on the same horizontal plane. This is shown in the figure below.

- Pendulum type heavy duty piano hinge

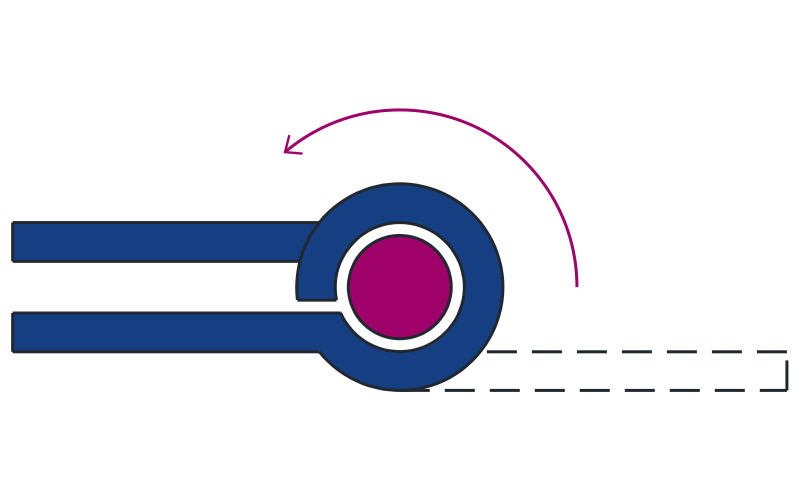

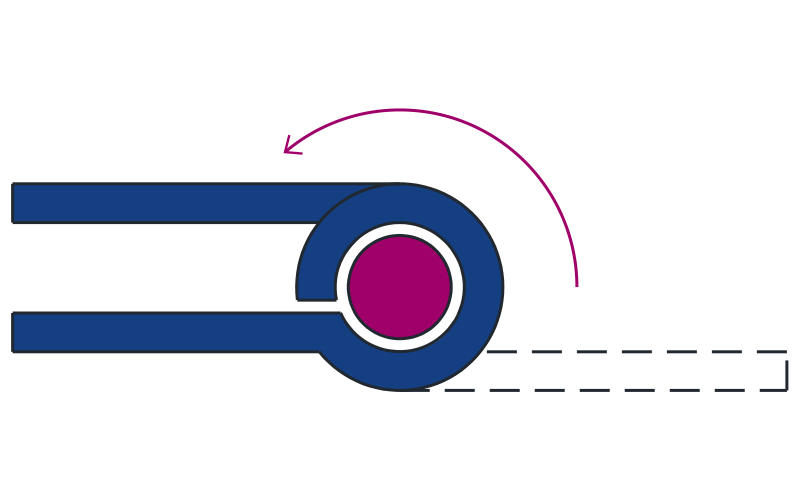

This form is similar to the first one, but the hinge blocks are positioned differently. The two hinge blocks are positioned in the middle of the hinge pins. This is shown in the figure below.

- Semi-symmetrical type

This is a combination of the normal type and the pendulum hinge. One of the hinge blocks is tangent to the diameter of the pin and the other hinge block is in the middle position of the hinge pin. This is shown in the figure.

There are many other types too numerous to list. I will list the structural diagrams of these forms so that it is clearer than the text.

What materials are used to produce heavy-duty piano hinges

They are made of a variety of materials, and here I will list three of the more commonly used materials.

- Iron

This material is the most economical one. A protective layer is usually made on its surface to improve the corrosion resistance of this material. This type of hinge is usually used in indoor environments.

- Stainless Steel

This material has good corrosion resistance and can be used in both indoor and outdoor environments. Heavy-duty piano hinges made of this material can be adapted to almost any potentially corrosive environment. Except in seaside or ocean conditions.

- Aluminum

Aluminum’s versatility makes it the most widely used metal after steel, due to its lightweight and corrosion resistance. However, we also use stainless steel for the pins of aluminum heavy-duty piano hinges.

How to buy heavy-duty piano hinges

Choosing a suitable heavy-duty piano hinge is not an easy job, especially when we need to order a heavy-duty piano hinge. You need to consider the weight, size, and structure of the door. You also need to consider the material, structure, finish, and load-bearing properties of the hinge.

Here is a professional article on how to buy piano hinges that may help you: Top 9 factors to consider when choosing piano hinges