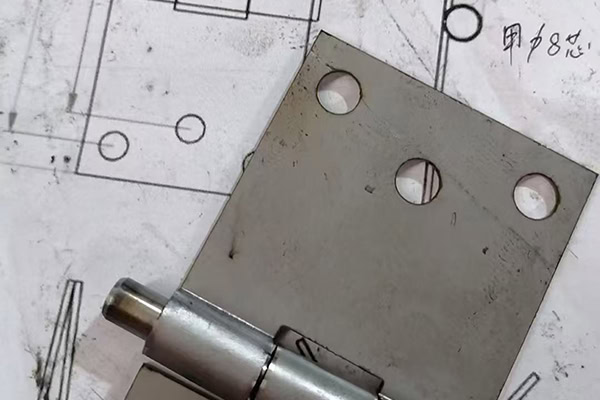

Heavy-duty gate hinges play a crucial role in maintaining the safety and performance of large industrial gates.

To maintain heavy-duty gate hinges in industrial settings, inspect them regularly, apply proper lubrication, tighten loose bolts, protect against corrosion, and replace damaged components promptly. These practices ensure reliability and prevent operational failures.

Explore the following proven methods to extend the life of your industrial hinges.

What Are the Most Common Issues with Heavy-Duty Gate Hinges?

Heavy-duty hinges face unique mechanical challenges due to constant exposure to vibration, weight load, and environmental factors. Misalignment and metal fatigue are among the most frequent issues, especially in industrial environments where doors are subject to thousands of cycles.

Heavy-duty gate hinges often fail due to misalignment, metal fatigue, corrosion, and bolt loosening. Identifying these issues early can prevent system-wide gate failures and costly downtime.

Misalignment and Wear Over Time

When hinges are not properly aligned during installation, they may twist or bow under gate pressure. Over time, this can cause the hinges to bind or even snap. Misalignment also increases the mechanical load on each hinge, accelerating wear. In high-cycle operations such as those in climatic test chamber hinges, regular inspections help detect these problems before they escalate.

Corrosion and Hardware Failures

Environmental exposure, particularly in coastal or high-humidity industrial areas, leads to accelerated rusting and hardware deterioration. Without routine checks and protective coatings, even corrosion resistant hinges can fail. Loose mounting bolts, often overlooked, also contribute to performance loss, gate sagging, and safety risks.

How Often Should You Inspect and Maintain Gate Hinges?

A structured maintenance plan is crucial for long-term hinge performance. Industrial hinges require more frequent inspections than residential ones due to increased stress and usage cycles.

For heavy-duty gate hinges in industrial environments, inspect monthly and conduct full maintenance quarterly. Increase frequency in high-vibration or corrosive environments.

Inspection Frequency by Environment

| Environment Type | Inspection Frequency | Full Maintenance |

|---|---|---|

| Indoor Factory | Monthly | Every 6 Months |

| Outdoor Industrial (e.g., outdoor industrial hinges) | Every 2 Weeks | Quarterly |

| Coastal/Marine | Weekly | Every 2–3 Months |

Key Inspection Tasks

Routine checks should cover hinge alignment, bolt tightness, and lubrication condition. Use a checklist to standardize procedures across facilities. Tracking wear data helps determine when it’s time to replace industrial door hinges proactively.

What’s the Best Lubricant for Industrial Gate Hinges?

Proper lubrication ensures smooth motion and protects against wear and corrosion. The choice of lubricant depends on the hinge type and environmental conditions.

Use lithium grease or synthetic industrial lubricants for heavy-duty hinges. Avoid household oils. Reapply lubricant every 1–2 months in harsh conditions.

Recommended Lubricants

For industrial gates using heavy duty truck door hinge setups, high-load lithium-based grease works best. In environments exposed to moisture or chemicals, silicone or Teflon-based lubricants provide better resistance.

Lubrication Process

Clean the hinge thoroughly before applying lubricant. Rotate the hinge to distribute the grease evenly. For applications involving piano hinges or continuous-use doors, an automatic lubricator can reduce manual work and ensure consistency.

How Can You Prevent Corrosion in Outdoor Hinges?

Corrosion is one of the leading causes of premature hinge failure in industrial environments. Preventing it involves material selection, protective coatings, and routine maintenance.

To prevent corrosion, choose zinc-plated or stainless steel hinges, apply rust-inhibiting coatings, and regularly clean off contaminants.

Best Practices for Corrosion Prevention

-

Apply anti-corrosion spray every 2–3 months.

-

Use epoxy or powder-coated strap hinges for high-moisture areas.

-

Store spare parts in dry, ventilated spaces.

-

For doors exposed to salt or chemical vapors, use marine hinges or specially coated alloys.

Material Selection Matters

Consider using aluminum hinges or aluminum geared continuous hinges in areas where weight and corrosion resistance are key concerns. These materials combine strength with longevity and are ideal for outdoor industrial settings.

How to Adjust Gate Hinges for Proper Alignment?

Misalignment can lead to hinge binding, increased friction, and long-term structural damage. It’s important to realign hinges at the first sign of uneven movement or visible sagging.

Realign gate hinges by loosening mounting bolts, repositioning the hinge for straight alignment, then re-tightening with locking fasteners. Use a level for precision.

Tools and Steps

-

Tools: Allen wrench, level, measuring tape, and thread locker.

-

Step 1: Support the gate to relieve pressure on the hinges.

-

Step 2: Loosen bolts and shift the hinge position slightly.

-

Step 3: Confirm level and plumb alignment.

-

Step 4: Tighten bolts using thread locker to prevent future loosening.

When to Adjust

Signs that adjustment is needed:

-

Door scraping the ground

-

Uneven gaps between door and frame

-

Resistance during opening or closing

If adjustments are frequent, consider upgrading to take-apart hinges or detachable hinges that allow easier repositioning.

Why Tightening Mounting Bolts Is Critical?

Loose bolts are a hidden threat to hinge longevity. Constant motion, especially in automated systems, gradually loosens connections.

Regularly check and tighten hinge mounting bolts to prevent misalignment, sagging, and mechanical failure. Use locking nuts or thread sealant to improve durability.

Preventative Fastening Techniques

-

Use lock washers or self-locking nuts.

-

Apply thread sealant to prevent vibration-related loosening.

-

Inspect bolt threads for wear during each maintenance cycle.

Bolt Grade Considerations

Select industrial-grade bolts (Grade 8 or stainless steel) for installations involving high-torque or heavy-load gates. This is particularly important when using butt hinges or weld on hinges in dynamic environments.

When Is It Time to Replace Heavy-Duty Hinges?

Even the strongest hinges have a finite life cycle. Watch for signs that indicate degradation beyond repair.

Replace hinges when you notice deformation, visible cracks, excessive play, or recurring misalignment issues. Prioritize safety over temporary fixes.

Common Replacement Indicators

-

Door won’t stay aligned after multiple adjustments

-

Audible squeaking or grinding despite lubrication

-

Visible rust pitting or fractures in hinge leaves

-

Broken welds or bent arms in staked hinges

Upgrade Suggestions

Opt for upgraded designs such as soft close hinges for smoother operation or cold storage room hinges for insulated environments. Many modern hinges also allow custom branding or laser engraving, which enhances traceability in industrial use.

How to Reduce Gate Sagging in Large Industrial Doors?

Sagging is a common mechanical failure, particularly with large or frequently used gates. It’s usually caused by excessive load or poor weight distribution.

To reduce sagging, use two or more heavy-duty hinges, ensure even weight distribution, and install limiters or support wheels if necessary.

Engineering Solutions

-

Use reinforced brackets and distribute load between top and bottom hinges.

-

Integrate diagonal bracing in gate design.

-

Add a spring-loaded wheel to support the gate’s far end.

Product Adaptation

For oversized metal enclosures or trailer access points, trailer door hinges with reinforced pivot points can help mitigate sag over time.

Should You Use Maintenance-Free Hinges for Industrial Applications?

Maintenance-free hinges are a cost-effective solution for high-cycle or hard-to-access installations. They require no lubrication and are often sealed for life.

Maintenance-free hinges reduce downtime and labor costs. Ideal for high-cycle, remote, or sealed environments.

Advantages

-

Lubricated and sealed during manufacturing

-

No need for scheduled greasing

-

Longer service intervals reduce labor cost

Ideal Use Cases

These hinges are commonly used in:

-

Enclosed production environments

-

Automated doors

-

Critical-use applications like clean rooms or heavy-duty trucks

Why Standardized Maintenance Plans Are Essential for Factories?

Without a clear schedule, hinge maintenance is often reactive rather than proactive, leading to unexpected failures.

A standardized hinge maintenance plan reduces failures, extends component life, and improves workplace safety.

Implementation Steps

-

Develop a digital checklist integrated with facility management software

-

Assign trained personnel to oversee hinge inspections

-

Maintain detailed logs for each hinge type (e.g., importance of lubrication for heavy-duty barrel hinges)

Sample Plan Structure

| Task | Frequency | Responsible Role |

|---|---|---|

| Visual Inspection | Weekly | Maintenance Technician |

| Lubrication | Monthly | Maintenance Engineer |

| Corrosion Check & Cleaning | Quarterly | Quality Inspector |

| Replacement Evaluation | Semi-Annually | Purchasing Director |

Conclusion

Routine inspection, proper lubrication, and timely replacement are essential to maintain heavy-duty gate hinges in industrial environments. Choose the right hinge type and establish a long-term maintenance schedule to prevent failure and downtime.