Industrial stainless steel hinges are often judged by their performance, not their polish. So, is mirror finishing really necessary in heavy-duty applications?

Mirror polishing is usually unnecessary for industrial stainless steel hinges. These hinges are built for rugged use, not visual appeal. The polishing process is labor-intensive, increases cost, and adds no functional or corrosion-resistant benefits. In most industrial settings, the appearance of the hinge is irrelevant compared to durability, precision, and reliability.

Let’s examine what mirror polishing involves—and why it may not suit industrial-grade stainless steel hinges.

What Are Industrial Stainless Steel Hinges?

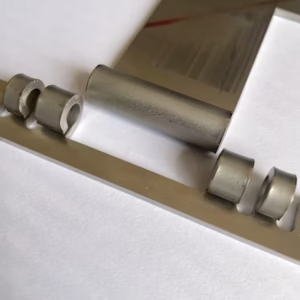

Industrial stainless steel hinges are mechanical components that enable controlled movement or rotation between two connected surfaces. They are designed for performance in demanding environments such as electrical enclosures, testing equipment, transportation systems, and manufacturing machinery. Common materials include SS304 and SS316 stainless steel, offering excellent corrosion resistance and strength.

These hinges come in various configurations tailored to specific applications. For example, cold storage room hinges are optimized for low-temperature environments, while Heavy Duty Continuous Hinges offer long spans of support for large doors. Others, like Friction hinges in industrial applications, provide controlled motion in adjustable panels or access doors.

These hinges differ sharply from those used in residential or architectural settings. Industrial applications require robust materials, thicker leaf gauges, and precise tolerances to ensure reliability and safety under stress.

What Is Mirror Polishing in Stainless Steel Finishing?

Mirror polishing is a multi-step surface treatment that grinds and buffs stainless steel to a highly reflective, mirror-like finish. It involves several stages of mechanical abrasion—starting with coarse sanding and ending with fine polishing using compounds and high-speed buffers. The result is a surface with a Ra (roughness average) of less than 0.2 μm.

According to industry sources like Fein and Norton Abrasives, mirror polishing requires a combination of flap discs, felt wheels, and polishing pastes to achieve consistent shine. The most common standards include No.8 finish (mirror) and 2B finish (matte). No.8 is typically used for aesthetic purposes, such as in the food, pharmaceutical, and cleanroom industries.

However, achieving this finish on complex hinge geometries is especially challenging. Standard machines struggle to polish intricate corners or edges, meaning skilled manual labor is often required. This makes the process expensive, time-consuming, and inefficient for most industrial applications.

Why Industrial Stainless Steel Hinges Don’t Need Mirror Polishing

1. Function Over Aesthetics in Industrial Settings

Industrial components prioritize functionality over looks. Hinges are typically concealed inside machinery, equipment panels, or enclosure doors where aesthetics hold little to no value. Most of the time, customers in sectors such as electrical manufacturing, test chambers, and logistics care only about whether the hinge performs under load and resists wear—not whether it shines.

Even in outdoor environments, where exposure to weather is a concern, the priority lies in corrosion resistance, not visual appearance. For example, outdoor industrial hinges must withstand UV, moisture, and dirt without failing structurally—none of which require a mirror finish.

2. High Cost and Labor-Intensive Process

Polishing stainless steel to a mirror finish—especially with irregular or complex parts like hinges—is labor-heavy and slow. CNC finishing machines can handle flat surfaces efficiently, but most industrial hinges (especially custom ones) have complex curves, recesses, and pivoting joints that require manual buffing.

Communities like Practical Machinist and Reddit emphasize that achieving a true mirror finish is an exhausting process, often not worth the outcome in non-decorative parts. This is particularly true for Adjustable Torque Stainless Steel Hinge types or multi-joint friction hinges, where each moving part must be treated individually.

Additionally, in a production setting where batch volumes are high, mirror polishing is impractical. It not only slows down manufacturing timelines but also increases dependency on experienced labor, which adds unpredictability and cost.

3. No Additional Corrosion or Surface Protection

Unlike electroplating or coating, mirror polishing does not enhance the corrosion resistance of stainless steel. The polish may temporarily improve the passive layer’s formation, but this benefit is marginal and short-lived. Stainless steel, especially grades like 316, already possess excellent corrosion resistance, which is more than sufficient for most industrial applications.

Other protective treatments—such as passivation or shot peening—can offer better long-term protection without the drawbacks of polishing. So when using premium materials like those in 316 Stainless Marine Friction Hinges, polishing does little to enhance durability.

Moreover, mirror-finished surfaces may appear clean at first but can trap contaminants or oxidize under tough environmental conditions—especially in industrial zones with exposure to chemicals, oils, or metal dust.

4. Poor Practicality in Harsh Environments

In most industrial scenarios, mirror-polished surfaces quickly lose their shine. They are prone to fingerprints, smudges, and scratches—even light contact with tools or gloves can damage the surface. Once scratched, a mirror finish becomes visually uneven and harder to clean, requiring more maintenance than brushed or matte finishes.

This makes them unsuitable for environments such as factories, outdoor equipment, transport trucks, or testing equipment—all of which subject hinges to friction, vibration, and dirt. A Heavy Duty Truck Door Hinge polished to a mirror shine would likely be scratched within days, if not hours, of installation.

When Mirror Polishing Might Be Justified in Industrial Applications

There are exceptions where mirror polishing may be appropriate—even in industrial environments. These include:

-

Cleanroom and medical environments where surface smoothness reduces bacteria accumulation.

-

High-end branded equipment where a polished finish is part of the company’s visual identity.

-

Hygiene-critical applications, such as pharmaceutical machines or food-grade processing units.

In such cases, mirror polishing may be specified by the client, especially if they’re exporting to Western markets with strict compliance standards. For these niche requirements, manufacturers like IHINGES are capable of delivering mirror-finished components upon request—but with clear communication about increased cost and lead time.

IHINGES’ Perspective as a Professional Manufacturer

At IHINGES, we believe in value-driven manufacturing. Mirror polishing offers little functional benefit for the vast majority of industrial stainless steel hinges. Our clients—from test equipment makers to sheet metal fabricators—care more about lifespan, precision fit, and corrosion resistance.

That’s why our hinges, including options like heavy duty hinges and ball bearing butt hinges, are finished with the right balance of surface treatment and production efficiency. We offer 3D design services, fast prototyping, and tailored finishing based on the real demands of your application—not cosmetic trends.

Should your project truly require mirror polishing, we’ll deliver it. But we’ll also make sure you know when it’s unnecessary.

Conclusion

In industrial applications, mirror polishing adds cost without improving function. Unless your use case requires it for hygiene or branding, it’s better to focus on strength, reliability, and material quality.