Description

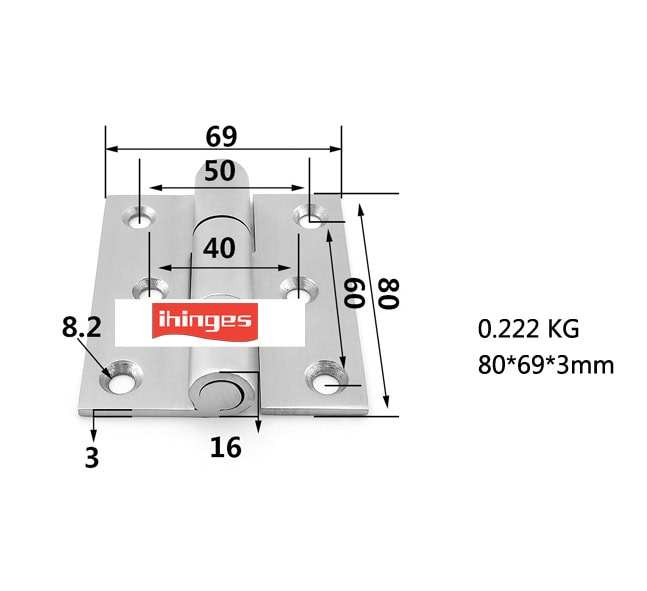

The ML2-JL402-3 model hinge is crafted from 3mm thick 304 stainless steel using high-precision stamping technology. With an overall size of 80×69mm, this hinge is ideal for medium-duty applications that require both strength and corrosion resistance. It features a brushed satin finish, a welded pin on one end, and six countersunk mounting holes (Ø8.2mm), ensuring both ease of installation and long-term durability. Its reinforced knuckle and compact footprint make it suitable for demanding environments such as industrial machinery panels, metal enclosures, and access doors.

Parameters

| Item | Specification |

|---|---|

| Product Model | ML2-JL402-3 |

| Overall Dimensions | 80mm × 69mm |

| Thickness | 3mm |

| Material | 304 Stainless Steel |

| Surface Finish | Brushed / Satin |

| Pin Diameter | 16mm |

| Pin Type | Welded on one end |

| Mounting Hole Diameter | Ø8.2mm |

| Mounting Holes | 6 (3 per leaf) |

| Weight | 0.222 kg |

| Customization | Logo, hole size, mounting layout |

Features

-

Stamped from 304 Stainless Steel: Offers excellent corrosion resistance, strength, and long service life.

-

Welded Pin Design: Prevents accidental pin removal, enhancing hinge reliability during operation or vibration.

-

Brushed Finish: Provides a refined industrial look and improves resistance to wear and environmental factors.

-

Efficient Mounting: Six countersunk holes ensure secure and flush installation on flat surfaces.

-

Precision Structure: Designed for smooth operation and tight hinge alignment under repeated use.

Applications

-

Control and distribution box doors

-

Industrial and electrical enclosures

-

Access panels on machinery or test equipment

-

HVAC and cleanroom doors

-

Stainless steel cabinets or frames

Why Weld One End of the Hinge Pin?

Welding one end of the pin ensures it remains fixed during installation and usage, preventing unintentional disassembly or misalignment. This is particularly valuable in environments where equipment is subject to vibration, frequent access, or movement. A welded pin design enhances safety, durability, and low maintenance performance—ideal for high-reliability applications.