Description

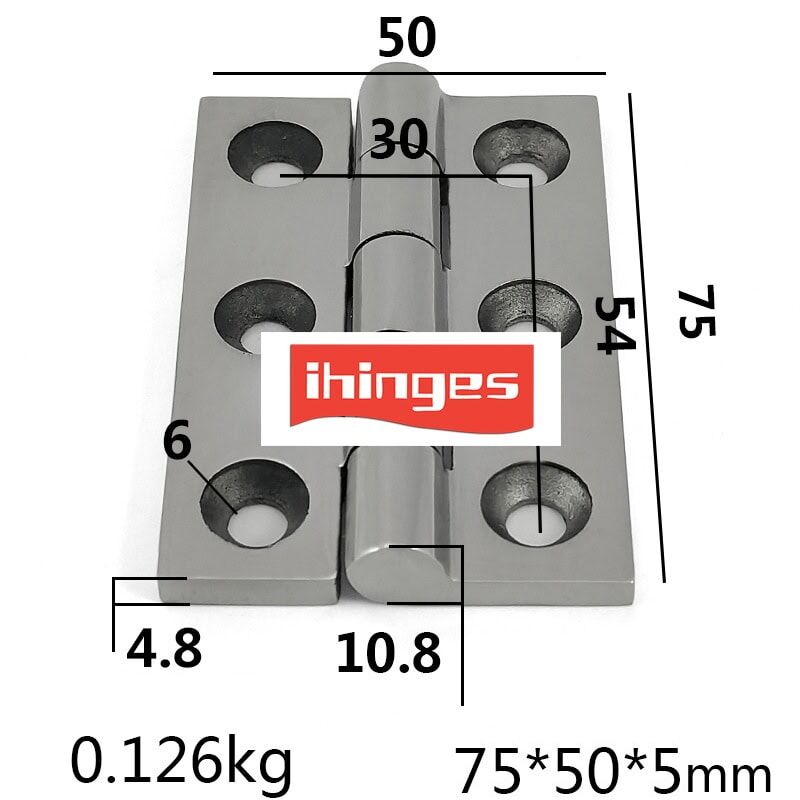

The ML2-JL1013-1 stainless steel industrial hinge from IHINGES is specially designed for industrial applications requiring moderate to high load-bearing strength. With dimensions of 75×50×4.8mm, this hinge is compact yet structurally strong, making it suitable for sheet metal doors, equipment covers, and industrial cabinets. It is crafted from durable 304 stainless steel and features a mirror-polished finish for a clean, professional appearance. The countersunk mounting holes ensure that screw heads are flush with the hinge surface, providing a sleek and safe installation. Each hinge can support up to 40kg and can be customized to fit specific project requirements.

Parameter

| Item | Specification |

|---|---|

| Product Name | Stainless Steel Industrial Hinge |

| Model Number | ML2-JL1013-1 |

| Brand Name | IHINGES |

| Material | Stainless Steel 304 |

| Surface Treatment | Mirror Polished |

| Overall Dimensions | 75mm × 50mm × 4.8mm |

| Hinge Thickness | 4.8mm |

| Weight | 0.126kg |

| Load Capacity (per hinge) | Up to 40kg |

| Hole Diameter | 6mm |

| Mounting Hole Spacing | 30mm (center-to-center) |

| Installation Type | Countersunk (flush mounting) |

| Customization | Logo, Dimensions, Hole Layout |

Features

-

High Load Capacity: Supports up to 40kg per hinge, ideal for sheet metal and industrial doors.

-

Compact and Efficient Design: Small footprint (75×50mm) with precision-machined mounting holes.

-

Polished Finish: Mirror polishing enhances aesthetics and improves surface corrosion resistance.

-

Flush Surface: Countersunk hole design ensures screw heads do not protrude, maintaining a smooth finish.

-

Flexible Customization: Adaptable to various sizes, mounting requirements, and surface treatments.

Application

This hinge is widely applied in:

-

Industrial sheet metal doors

-

Electrical enclosures and control boxes

-

Test chamber access panels

-

Instrumentation and machinery housings

-

OEM equipment requiring precise hinge fitting

Screw Mounting vs. Welding Installation

Screw Mounting offers flexibility and ease of installation. It allows for easy replacement or repositioning of the hinge during maintenance or upgrades. It is also ideal for enclosures or assemblies that need to be frequently accessed or adjusted.

Welding Installation, on the other hand, provides a permanent and extremely strong bond, making it suitable for high-vibration environments or applications where tamper-proofing is necessary. However, it requires more time and precision during the installation process and is less convenient to modify after the fact.

Choosing between the two depends on the specific application requirements, including the need for adjustability, the working environment, and the desired appearance.