Description

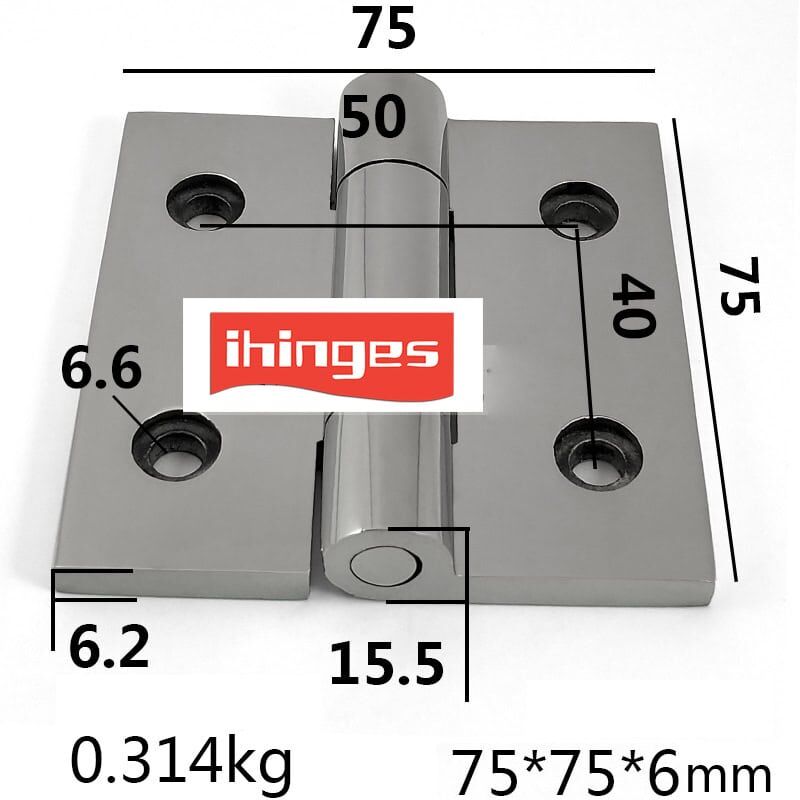

The ML2-JL1012-3 stainless steel industrial hinge from IHINGES is engineered for high-load sheet metal doors, equipment panels, and industrial enclosures. With dimensions of 75×75×6.2mm and a robust design, this hinge is ideal for applications requiring both strength and a clean, professional appearance. It features a mirror-polished finish and countersunk mounting holes, ensuring a flush surface without protruding screw heads. Made from high-quality 304 stainless steel, it supports up to 50kg per hinge and can be customized to meet specific installation requirements.

Parameter

| Item | Specification |

|---|---|

| Product Name | Stainless Steel Industrial Hinge |

| Model Number | ML2-JL1012-3 |

| Brand Name | IHINGES |

| Material | Stainless Steel 304 |

| Surface Treatment | Mirror Polished |

| Overall Dimensions | 75mm × 75mm × 6.2mm |

| Hinge Thickness | 6.2mm |

| Weight | 0.314kg |

| Load Capacity (per hinge) | Up to 50kg |

| Hole Diameter | 6.6mm |

| Mounting Hole Spacing | 50mm (center-to-center) |

| Installation Type | Countersunk (flush mounting) |

| Customization | Logo, Dimensions, Hole Layout |

Features

-

Heavy Load Bearing: Each hinge can support up to 50kg, suitable for industrial-grade doors.

-

Mirror Polished Surface: High gloss finish provides a clean, modern look with excellent corrosion resistance.

-

Thick and Durable: 6.2mm thick 304 stainless steel ensures structural stability and longevity.

-

Flush Installation: Countersunk holes enable a smooth surface without protruding fasteners.

-

Flexible Customization: Adaptable in size, hole configuration, and logo engraving based on client needs.

Application

Widely used in:

-

Industrial equipment enclosures

-

Electrical control cabinets

-

Environmental test chamber doors

-

Machinery access panels

-

Precision sheet metal installations

Advantages of Countersunk Installation

Countersunk mounting allows the hinge to sit flush with the surface, preventing any screws or bolts from sticking out. This not only enhances the overall appearance but also reduces the risk of snagging or mechanical interference. It’s particularly useful in environments where a clean, smooth finish is essential for safety, hygiene, or aesthetics. This installation method is preferred for high-end equipment and enclosures where precision and design are critical.