It’s a common oversight in the industrial world to assume that ‘a hinge is just a hinge’. But when it comes to the pivotal difference between heavy machinery and light industrial equipment, could it be that the hinges play a much larger role than we realize? The nuances of machinery, the demands they are subjected to, and the environments in which they operate can change the game entirely.

Indeed, there are specific hinges tailored for heavy machinery versus light industrial equipment. Heavy machinery hinges prioritize weight-bearing capabilities, durability, and safety, often crafted from robust materials and designed to withstand immense stress. In contrast, light industrial equipment hinges, while still requiring durability, often offer more flexibility in movement and may be made from a broader range of materials.

Understanding the significance and function of these hinges is essential for ensuring equipment longevity, safety, and optimal performance. Let’s delve into the distinctions and needs that arise in this field.

Weight Bearing Capabilities

The primary distinction between hinges for heavy machinery and those for light industrial equipment is their weight-bearing capability. Heavy machinery hinges are designed to support tremendous weights, often several tons, and can endure the stress without warping or breaking. Light industrial equipment, while still requiring sturdy support, may not be subjected to the same intense pressure and weight.

The structural integrity of a hinge used in heavy machinery is critical. Even a minor flaw or miscalculation in the design or installation of these hinges can lead to catastrophic results. They are typically made of high-strength materials and undergo rigorous testing. In contrast, while the hinges for light industrial equipment still need to be durable, they are usually made with more flexibility in design, catering to a variety of applications and weight requirements.

Material Composition

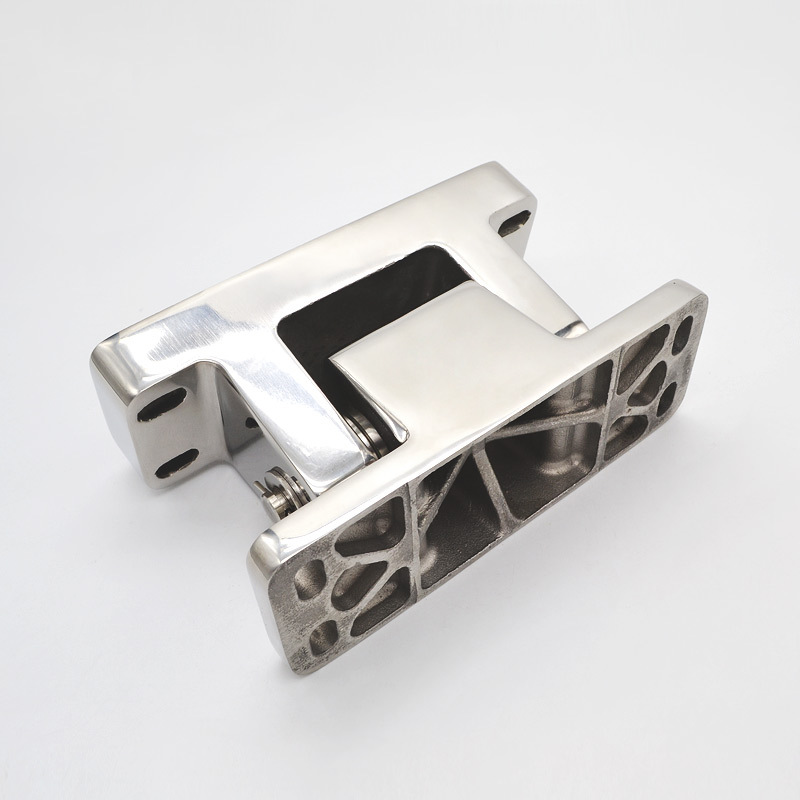

Different machines require hinges made of different materials, depending on their application. For instance, heavy machinery operating in corrosive environments might need hinges made of stainless steel or other resistant materials.

The choice of material directly affects the hinge’s lifespan and functionality. For heavy machinery exposed to elements like saltwater or chemicals, corrosion-resistant hinges are a must. Light industrial equipment hinges might be crafted from lighter metals or even durable plastics, depending on their operational environment and purpose.

Maintenance Needs

While all hinges require periodic maintenance, those for heavy machinery often need more frequent checks due to the extreme stresses they experience. Light equipment hinges might have longer intervals between necessary maintenance.

The maintenance needs arise from wear and tear, environmental factors, and the physical stress the machinery undergoes. Regular inspections, lubrication, and replacements ensure that heavy machinery operates without hitches, while lighter equipment, with lesser wear and tear, might not demand as rigorous a maintenance schedule.

Cost Implications

Due to the robust materials and design intricacies, hinges for heavy machinery tend to be more expensive than those for light industrial equipment.

The cost difference isn’t merely because of the materials. It’s also about the research and development, testing phases, and manufacturing precision required for heavy machinery hinges, which substantially increases their market price. Light equipment hinges, while still needing to be reliable, can be produced more economically due to fewer stringent requirements.

Load Distribution

The way hinges distribute load is crucial. Heavy machinery hinges are designed to distribute loads evenly, preventing undue stress on any particular point. Light industrial equipment hinges may not always need such precision.

Uneven load distribution can lead to quicker wear, potential malfunction, or even catastrophic failure. For heavy machinery, it’s crucial that the hinge’s design and placement ensure even load distribution. Lighter equipment hinges might offer more leeway in this aspect but still play a pivotal role in the machine’s overall function.

Flexibility & Movement

Certain applications might require hinges that offer a greater range of movement or flexibility. While heavy machinery might have hinges designed for limited movement but maximum strength, light equipment might prioritize flexibility.

The range of movement is often dictated by the machinery’s purpose. A heavy crane might need robust hinges that move within a limited scope but can bear immense weight. On the other hand, a light assembly robot might need hinges that allow for varied angles and rotations but don’t need to support excessive weight.

Lifespan & Durability

Hinges for heavy machinery, given their rigorous design and robust materials, typically have a longer lifespan than those for light industrial equipment, even though they are subjected to greater stresses.

The investment in high-quality materials and design for heavy machinery hinges ensures they can withstand prolonged usage under challenging conditions. While light equipment hinges may not endure the same levels of stress, they are designed for their specific operational requirements, balancing longevity with cost-effectiveness.

Safety Implications

Lastly, the safety implications cannot be stressed enough. Faulty or inadequate hinges can pose significant safety risks, especially in heavy machinery where a hinge failure could lead to disastrous consequences.

Regular inspections, using the right type of hinge for the application, and adhering to manufacturer guidelines ensure safe operations. Both heavy machinery and light industrial equipment hinges play a crucial role in ensuring operator and workplace safety.

Conclusion

While both heavy machinery and light industrial equipment have their unique hinge requirements, understanding these differences is pivotal for optimal performance, safety, and longevity. Investing in the right hinge is an investment in the machinery’s future and operational efficacy.

You might also be interested: