Heavy duty continuous hinges offer essential support for industrial doors and enclosures operating in extreme environments.

Heavy duty continuous hinges provide full-length support, superior load distribution, and enhanced durability in high-stress environments. Ideal for industrial applications like electrical enclosures and equipment doors, these hinges reduce wear, extend lifespan, and resist corrosion—even under high traffic and harsh environmental conditions.

Let’s explore the top five advantages that make these hinges essential for challenging industrial and manufacturing environments.

1. Superior Load Distribution

Heavy duty continuous hinges distribute weight evenly along the entire length of the door, reducing stress on individual fasteners and mounting points.

Unlike traditional hinges that rely on a few mounting points, continuous hinges — often referred to as piano hinges — offer uninterrupted support from top to bottom. This design minimizes torsion and prevents sagging, especially on tall or heavy doors like those found on industrial ovens or test equipment enclosures.

This feature is particularly useful when replacing conventional hinges in settings that experience constant vibration or repetitive use. It’s also a common upgrade option when companies need to Replace Industrial Door Hinges with more reliable, low-maintenance alternatives.

| Hinge Type | Load Distribution | Stress Points | Suitable Use Cases |

|---|---|---|---|

| Butt Hinges | Partial | High | Small access panels |

| Ball Bearing Butt Hinges | Moderate | Medium | Medium-sized control panels |

| Continuous Hinges | Full-length | Low | Large, heavy industrial doors |

2. Enhanced Durability in Harsh Environments

Made from corrosion-resistant materials like stainless steel, these hinges are built to withstand moisture, chemicals, and temperature extremes.

In industries such as marine engineering, food processing, and chemical manufacturing, hinges are regularly exposed to corrosive agents. Continuous hinges crafted from 316 stainless steel or finished with Electro-Galvanized and Hot-Dipped coatings provide excellent long-term resistance to rust and environmental degradation.

For instance, 316 Stainless Marine Friction Hinges are commonly used on outdoor enclosures and marine-grade equipment because of their strength and reliability under saltwater exposure. They are ideal for offshore rigs, wastewater treatment facilities, or coastal industrial installations. These hinges support uninterrupted operation with minimal maintenance requirements.

3. Increased Security and Tamper Resistance

Continuous hinges reduce gaps and exposure, making doors harder to pry open—essential in secure enclosures and industrial cabinets.

A full-length hinge significantly reduces the number of access points on a door, making it harder for intruders to exploit gaps or leverage weaknesses. This is critical in protecting sensitive equipment such as control panels, automation systems, and testing chambers.

Security features such as staked pin designs, concealed fasteners, and non-removable pins further enhance resistance to tampering. When integrated with Electrical Panel Hinges or mounted inside sealed units, continuous hinges provide both protection and reliability, making them a staple in defense and aerospace manufacturing sectors.

4. Extended Service Life and Low Maintenance

Fewer moving parts and full-length support mean less wear and tear, leading to a longer hinge lifespan and reduced service intervals.

Continuous hinges are engineered to operate thousands of open/close cycles without the typical wear seen in segmented hinge systems. With all weight evenly supported, there is significantly less stress on the door leaf and hinge points. Over time, this translates to fewer breakdowns and service calls.

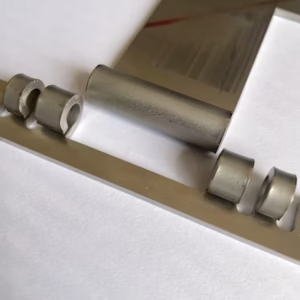

Hinges such as Heavy Duty Detachable Barrel Hinges or Take-Apart Hinges also enable easy removal for cleaning or replacement, especially useful in industries with strict hygiene protocols. Additionally, self-lubricating models or versions with polymer bushings offer silent, frictionless motion—ideal for cleanroom or electronic assembly lines.

5. Smooth, Vibration-Free Operation

Heavy duty continuous hinges provide stable, rattle-free movement, ideal for sensitive equipment or mobile machinery.

In high-vibration environments such as transport vehicles, robotics, or aerospace facilities, equipment integrity depends on components that resist motion distortion. Full-length hinges eliminate the play and rattling often found with traditional designs.

Products like Adjustable Torque Stainless Steel Hinges and Adjustable Friction Hinges are built for precise motion control. Their ability to maintain fixed positions or provide resistance against free movement is valuable in testing equipment, medical devices, or automated production lines. These solutions not only ensure user safety but also extend the life of connected components.

Conclusion

Heavy duty continuous hinges are indispensable in harsh industrial environments, offering unmatched strength, durability, and stability. Their advanced engineering ensures secure, long-lasting performance in even the most demanding applications.