Improperly installed door hinges can compromise function, safety, and structural integrity in industrial equipment.

Common industrial hinge installation mistakes include ignoring door weight, incorrect mortising, wrong screw use, improper spacing, and using non-corrosion-resistant materials. These issues lead to sagging, misalignment, or even failure of the equipment doors.

Avoiding these mistakes is essential for ensuring durability, safety, and long-term operational stability.

Not Considering Door Weight in Industrial Applications

Hinge selection must begin with an accurate understanding of the door’s total weight, especially in equipment housing and access panels.

Using hinges without matching them to door weight leads to sagging, misalignment, or eventual hinge breakage under load.

Matching Hinges to Door Weight

Industrial doors, especially those on climatic test chambers, cold storage units, or machinery enclosures, can weigh over 150 lbs. Standard hinges may not suffice. For heavier panels, heavy duty hinges or weld on hinges offer better durability.

Improperly matched hinges result in premature wear, excessive force on the fasteners, and structural stress on the frame. Buyers sourcing from manufacturers should always request load data per hinge type.

Recommended Hinge Types by Weight

| Door Type | Suggested Hinge Type | Load Capacity |

|---|---|---|

| Sheet Metal Panel (~50 lbs) | Butt Hinges | Up to 60 lbs per pair |

| Trailer Door (~120 lbs) | Trailer Door Hinges | Up to 150 lbs per pair |

| Test Chamber Door (150+ lbs) | Heavy Duty or Weld-on Hinges | 200+ lbs per pair |

Always consult with hinge manufacturers for engineering specs and 3D drawings for accurate matching.

Incorrect Mortising Depth

Flush installation is critical for optimal door alignment and full closure in industrial setups.

Mortising too deep or shallow causes misalignment, frame interference, and security risks.

Mortising Best Practices

A mortise that’s too deep causes the leaf to sink below the mounting surface, while shallow cuts cause hinge projection—both leading to door binding. In environments like clean rooms or cold storage room hinges usage, this affects air tightness and thermal performance.

Use a router jig or CNC-guided millwork to ensure consistent mortise depth—typically 1/8 inch for standard leaf thicknesses.

Mortising Tolerances

| Hinge Type | Recommended Mortise Depth |

|---|---|

| Standard Butt Hinge | 1/8 inch |

| Concealed Hinges | Manufacturer specified |

| Aluminum Hinges | 1/16 to 1/8 inch |

Uniform mortising also prevents unnecessary force on the hinge knuckle during operation.

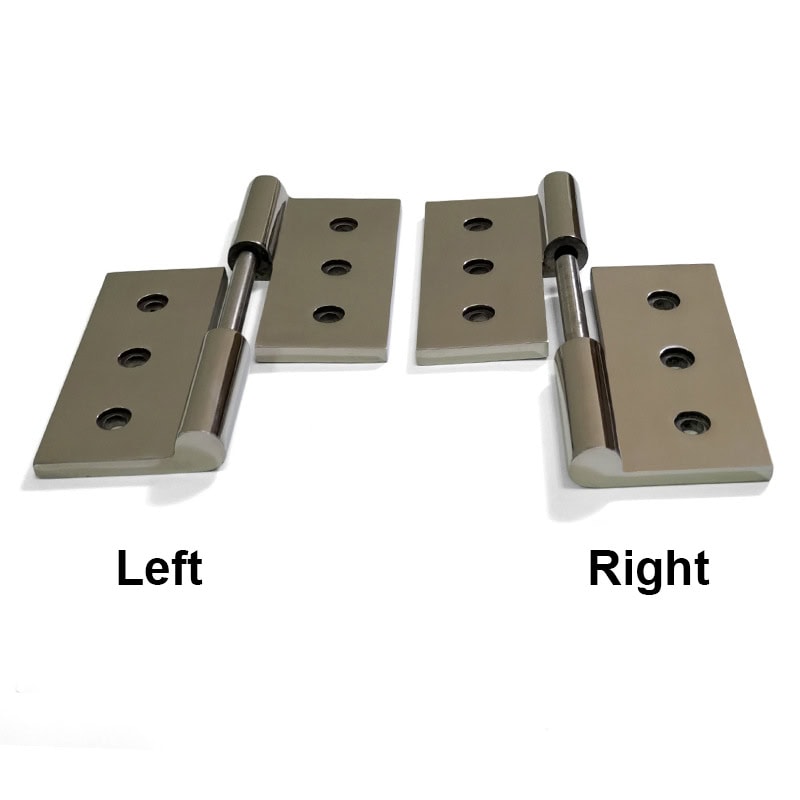

Hinge Placement on the Wrong Side

Installing hinges on the exposed side of an enclosure introduces severe security and functional risks.

External hinge placement allows tampering or hinge pin removal, especially on outdoor or transportable units.

Secure Hinge Positioning

For industrial use, hinges should be installed on the interior-facing side of the door whenever possible. If outer mounting is necessary, choose detachable hinges with tamper-resistant pins or marine hinges that offer pinless or sealed knuckle designs.

Applications like telecom cabinets or generator housings, when installed outdoors, are at higher risk if hinges are exposed.

Security-Oriented Hinge Solutions

| Risk Factor | Hinge Recommendation |

|---|---|

| Outdoor Use | Corrosion-resistant Marine Hinges |

| Theft/Vandalism | Tamper-Proof or Concealed Hinges |

| Easy Maintenance | Take-Apart / Detachable Hinges |

Additionally, hinge position should never interfere with door latching mechanisms or locking hardware.

Using Improper Screws for Load and Material

Screw failures are one of the most overlooked issues during industrial hinge installation.

Undersized or mismatched screws compromise holding strength, especially in metal panel doors or composite frame housings.

Screw Selection Principles

Fasteners must match both the hinge hole diameter and the substrate material (e.g., stainless screws for aluminum enclosures). For example, aluminum hinges used on sheet metal require self-tapping screws with matching threading.

Avoid pan-head screws in load-bearing hinge points; instead, use flat-head countersunk screws for flush seating and torque consistency.

Screw Type Recommendations

| Substrate | Screw Type | Thread |

|---|---|---|

| Steel Frame | Machine Screws + Lock Washers | Fine Thread |

| Aluminum Panel | Self-tapping Stainless Screws | Medium Thread |

| Wood Reinforced Core | Wood Screws (Brass/Stainless) | Coarse Thread |

Improper fastener use leads to screw pull-out, hinge looseness, or misalignment under cyclic loads.

Skipping Pilot Holes Before Installation

Driving screws directly without pilot holes can fracture the mounting surface or misalign the hinge.

Pre-drilled pilot holes prevent damage and ensure precise hinge alignment.

Importance of Pilot Holes

Pilot holes should be slightly smaller in diameter than the screw core and aligned perfectly with hinge holes. This is especially critical for thin-walled enclosures, aluminum profiles, or softwood core doors.

Using jigs or templates ensures repeatability, especially in mass production or during field retrofitting.

Drill Bit Sizing Guidelines

| Screw Size (Inches) | Pilot Hole Diameter |

|---|---|

| #6 | 7/64″ |

| #8 | 1/8″ |

| #10 | 9/64″ |

Pilot holes reduce torque resistance, improve screw penetration, and minimize cam-out during installation.

Conclusion

Avoiding these common hinge installation mistakes ensures safer, longer-lasting, and more reliable industrial door applications across sectors.