Customizing industrial hinges begins with one principle: design always follows the application’s unique requirements.

To customize an industrial hinge effectively, you must consider factors such as structure, load capacity, installation method, environment, materials, and budget. Each affects performance, durability, and cost.

Understanding these variables ensures the hinge functions properly and lasts in its intended setting.

Load Capacity

Load-bearing performance is the foundation of any hinge design.

A hinge must be engineered to support both the static and dynamic loads of the application to avoid failure.

Why Load Matters in Industrial Hinge Design

In industrial settings, hinge failure can cause major equipment downtime or safety issues. Therefore, accurate load calculation—including door weight, applied forces, and usage frequency—is essential. For example, heavy duty hinges are designed to support up to several hundred kilograms per hinge, making them ideal for large test chambers and heavy equipment doors.

When calculating load requirements, consider:

-

The weight of the moving part (e.g., a door or panel)

-

The number and placement of hinges

-

Dynamic loads such as slamming or vibration

Using undersized hinges leads to fatigue, deformation, or outright failure. Conversely, overengineering may unnecessarily raise costs. A well-balanced load analysis ensures performance and cost-efficiency.

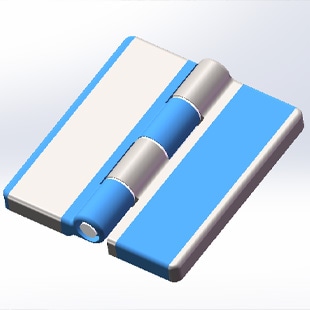

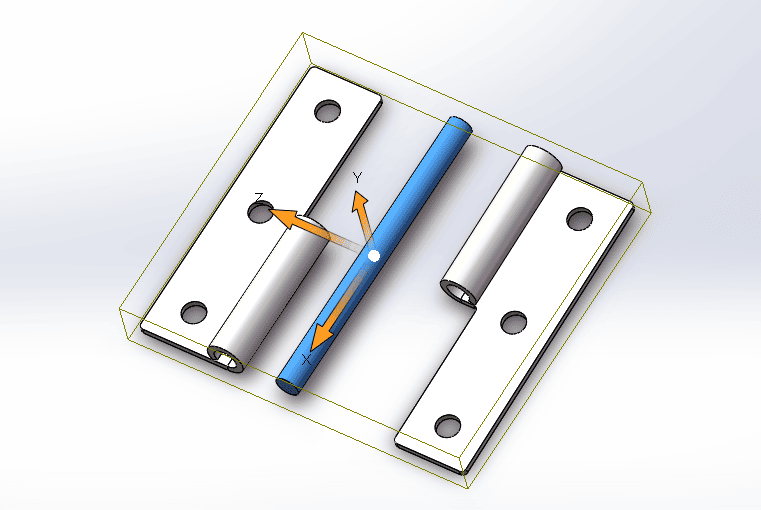

Hinge Structure & Type

The hinge’s structural design directly impacts functionality, maintenance, and appearance.

The correct hinge type depends on the motion required, space constraints, and mechanical forces involved.

Choosing the Right Hinge Structure

Different applications require specific hinge types:

-

Concealed hinges are often used for clean, enclosed surfaces.

-

Detachable hinges enable easy removal of doors or panels.

-

Piano hinges (continuous hinges) offer even load distribution over long surfaces.

Industrial applications often call for specialty types like cold storage room hinges or cam rise hinges, which assist with door lifting during opening. These not only improve ergonomics but extend hinge life by reducing friction.

Understanding motion paths (e.g., lift-off, swing-open, or folding) helps engineers determine whether a butt, concealed, or special hinge structure is optimal. Failure to match hinge structure with motion needs can lead to wear or misalignment.

Mounting Style

Hinge mounting style defines compatibility with the equipment or structure.

Selecting between weld-on, surface-mounted, or embedded styles affects assembly complexity and strength.

Installation Considerations in Custom Hinge Design

Weld-on hinges provide maximum durability and are ideal for permanent, high-load applications such as trailer door hinges or weld on hinges used in steel enclosures. However, they require precise alignment during installation and may complicate maintenance.

Surface-mounted options are easier to install and replace, making them suitable for modular industrial panels or enclosures. Bolt-through or screw-fixed mounts are common in aluminum or composite housings.

Considerations include:

-

Base material compatibility (e.g., aluminum vs. steel)

-

Assembly time and accessibility

-

Whether removability is required

Mounting style also influences how the hinge tolerates vibration and long-term wear—critical for moving equipment or transport vehicles.

Operating Environment

Environment affects material, coating, and hinge functionality.

High moisture, temperature extremes, and corrosive elements all influence the hinge’s longevity and safety.

Environmental Impact on Hinge Design

For example, marine hinges must resist salt spray corrosion, making 316 stainless steel or coated aluminum preferred choices. Hinges used in climatic test chambers must tolerate thermal cycling from -40°C to +150°C and avoid material deformation or expansion-induced locking.

Other environmental challenges include:

-

Dust and particles (requiring sealed or smooth-surface hinges)

-

Chemical exposure (demanding resistant finishes)

-

Outdoor UV exposure

Failing to match material and coating to the operating environment will lead to corrosion, reduced life, or operational failure. Ensure custom hinge specifications include detailed environmental conditions for accurate design.

Material Selection

Material determines a hinge’s mechanical properties and resistance to wear.

Selecting the appropriate material impacts strength, corrosion resistance, and cost-efficiency.

Common Industrial Hinge Materials

The most frequently used materials in industrial hinge applications include:

-

Stainless Steel (304/316) – Excellent corrosion resistance for humid or corrosive environments.

-

Aluminum – Lightweight and corrosion-resistant, commonly used in aluminum hinges.

-

Carbon Steel – Cost-effective and strong but requires protective coatings.

-

Zinc Alloy – Good for lower load, precise applications with complex shapes.

Selecting the correct material also involves understanding potential galvanic corrosion if different metals contact each other. Surface treatments such as anodizing, powder coating, or electropolishing enhance durability and appearance.

Matching material to budget and performance requirements is essential in producing an optimized custom hinge.

Frequency of Use

Industrial hinges experience varying levels of opening and closing cycles.

High-usage applications demand durable, fatigue-resistant designs.

Designing for Repetition

In test chambers or automated enclosures, hinges may open/close thousands of times per month. Over time, even minor flaws in design or material can lead to premature failure. Customization should include:

-

Hardened pins or bushings for wear resistance

-

Lubrication channels or self-lubricating materials

-

High-cycle tested components

For example, industrial refrigerator door hinges are designed for thousands of thermal and mechanical cycles without losing alignment or sealing pressure.

Specifying hinge life requirements in terms of cycles allows manufacturers to test and recommend the correct design before production.

Customization Requirements

Tailored hinges provide more value when aligned with application-specific needs.

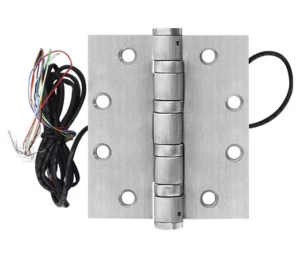

Customization includes size, surface finish, logo branding, special motion features, and packaging.

Going Beyond the Standard

Clients may request:

-

Custom opening angles (e.g., 135° or 180°)

-

Soft-close or spring-loaded mechanisms

-

Color-matching with housing or panel

-

Embossed company logos or serial number engraving

Special projects may even require special hinges with offset leaf designs or dual-axis movement. Early communication of these requirements reduces design revisions and improves lead time efficiency.

IHINGES can also provide 3D CAD models for faster integration into customer systems, shortening development cycles and ensuring precise fit.

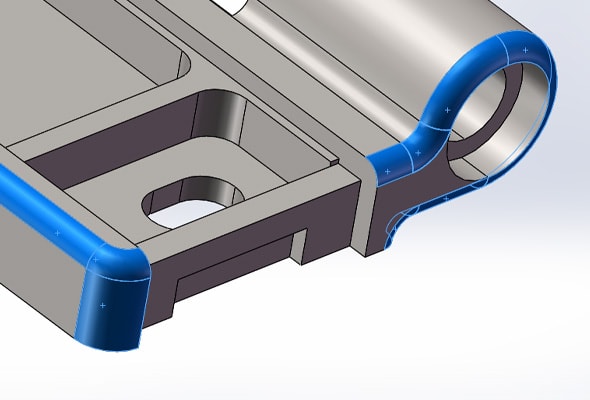

Dimensional Tolerance & Fit

Precision matters, especially in automated or sealed systems.

Incorrect tolerances lead to misalignment, binding, or operational failure.

Engineering for Fit and Function

High-tolerance hinge designs are crucial in:

-

Sheet metal enclosures

-

Climate chambers

-

Control boxes

Design teams must specify:

-

Pin diameter tolerances

-

Hole location accuracy

-

Leaf thickness consistency

Stacked tolerances across multiple mounting points can distort hinge alignment. That’s why CAD models and sample fittings are important in the prototyping stage.

Ensuring proper tolerances enhances not just movement but also long-term reliability and reduced maintenance.

Compliance & Certification

Some industries require certified components.

Hinges may need to comply with ISO, CE, RoHS, or other regional and industry standards.

Regulated Environments

Medical, military, and food processing applications often specify:

-

FDA-compliant materials

-

Fire-rating standards (e.g., UL)

-

EMI shielding for electronics enclosures

Working with certified suppliers ensures traceability and process consistency. For large OEMs or export-based customers, certification isn’t optional—it’s a basic requirement for doing business.

Early identification of compliance needs avoids delays during procurement or inspection stages.

Cost & Lead Time Considerations

Budget constraints often shape design decisions.

Balancing functionality with cost and production time is key in hinge customization.

Managing the Trade-Offs

More complex designs with higher-grade materials often mean longer lead times and higher cost. For example, CNC-machined components or surface treatments add days or weeks to the production cycle.

To optimize:

-

Use modular designs where possible

-

Confirm minimum order quantities early

-

Prioritize critical vs. cosmetic features

IHINGES offers flexible production batches and short-run customization for prototyping or urgent needs.

Conclusion

Designing industrial hinges requires careful consideration of load, structure, installation, materials, environment, and budget. Customization ensures the hinge works flawlessly in your application.