Selecting the right industrial hinge requires more than just knowing you need a hinge.

To get the right industrial hinge quickly, customers should provide detailed information including hinge type, mounting method, space limitations, load requirements, material preferences, and the operating environment. This helps manufacturers recommend precise solutions and avoid delays caused by miscommunication.

Clear technical input leads to faster response and better product matching.

What Is the Structure or Type of Hinge Needed?

Customers must specify the hinge structure they need based on function and application.

Different hinge types—such as butt hinges, detachable hinges, or heavy duty hinges—serve different purposes, and clearly identifying the type helps narrow down suitable options quickly.

Providing the right hinge type is the foundation of efficient communication. For instance, butt hinges are commonly used in standard industrial panels, whereas detachable hinges allow easy removal of equipment doors during maintenance.

Industrial uses may also require special hinge designs, such as trailer door hinges or climatic test chamber hinges, which are designed to perform under specific environmental or mechanical conditions.

Clarifying whether the hinge needs to be load-bearing, removable, or have a specific rotation range helps manufacturers immediately rule out unsuitable models and prepare viable samples or drawings.

Where and How Will the Hinge Be Installed?

Correct hinge selection depends heavily on its intended installation method and orientation.

Customers should provide installation location (vertical/horizontal), mounting surface details, and whether installation will be via screws, welding, or concealed mounts.

Knowing the hinge’s mounting location—internal or external—directly affects the recommended structure. For instance, weld on hinges are ideal for permanent, load-bearing assemblies on heavy enclosures or machinery, while concealed hinges are better for sleek, dustproof panel integration.

Also, customers should clarify if there’s a left-hand or right-hand swing, and whether access is needed from both sides. Providing CAD or 3D files further eliminates ambiguity, especially when the mounting surface includes reinforcements, curvature, or embedded hardware.

What Are the Load Requirements?

Load-bearing capacity is a key performance metric for industrial hinges.

Customers should indicate the weight of the door or component being supported, as well as whether the application involves static or dynamic forces.

Weight alone isn’t always sufficient. A cold storage room door, for instance, may only weigh 50 kg, but insulation, pressure differentials, and sealing force increase stress on the hinge mechanism. In contrast, machinery access panels may face vibrations or frequent impact loads during production.

High-performance applications may require heavy duty hinges engineered with internal bearings or double knuckles to distribute weight evenly. Including details like the width and height of the swinging part helps calculate torque requirements and select the correct pin diameter and leaf thickness.

What Materials Are Preferred or Required?

Material selection should align with environmental and mechanical demands.

Customers should specify preferred hinge materials—such as stainless steel, aluminum, or plated steel—based on corrosion resistance, weight, and mechanical strength.

For outdoor or marine environments, corrosion resistant hinges like stainless steel or marine hinges are vital to ensure long-term durability. Indoor lab enclosures might benefit from aluminum hinges, offering a lightweight, rustproof alternative for frequent access.

Also, customers should mention any necessary finishes—e.g., powder coating, electroplating, passivation—to meet aesthetic, hygiene, or regulatory requirements. If the application requires food-grade or medical compliance, selecting FDA-approved or antimicrobial finishes becomes essential.

What Is the Environmental Condition of Use?

Understanding the hinge’s working environment ensures long-term reliability.

Customers should outline environmental conditions such as temperature range, humidity, presence of chemicals, UV exposure, and outdoor or indoor usage.

Applications like climatic test chambers or outdoor electrical cabinets expose hinges to extreme conditions. High humidity and temperature fluctuations can degrade standard materials, so specialized outdoor industrial hinges with rubber seals or thermal resistance are preferable.

If used near saltwater or acid fumes, stainless 316 or coated aluminum hinges are necessary to resist pitting and corrosion. In contrast, a hinge inside a cleanroom or electronics lab may require dust-sealed or anti-static design features.

Are There Space or Clearance Limitations?

Tight spaces limit hinge size and swing radius.

Customers must provide the available space for hinge installation and required door opening angle to avoid mismatched sizes or interference.

For compact installations, like enclosures with adjacent panels, Aluminum Geared Continuous Hinges or piano hinges offer distributed load with minimal protrusion. Hinges designed with offset knuckles or slim profiles may be required to avoid collision during operation.

Providing dimensional constraints—like width between the panel edge and adjacent wall—can help engineers recommend optimal mounting strategies, such as inside-mount staked hinges or recessed designs.

What Are the Performance and Functional Requirements?

Performance needs dictate the mechanical structure of the hinge.

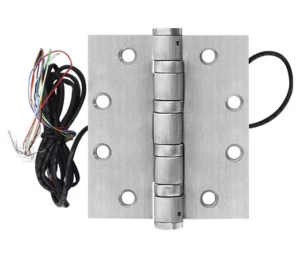

If the hinge requires soft closing, positioning, auto-return, or hold-open features, customers should communicate those expectations clearly.

Certain equipment doors need to stay open at 90° or auto-close after use. Hinges with torsion springs or damping mechanisms—like soft close hinges—offer that functionality but require customized internal components.

Functional attributes like anti-tamper pins, multiple stop positions, or built-in torque resistance help tailor the hinge to industrial safety or ergonomics needs. Identifying this upfront reduces costly redesigns after sampling.

What Is the Desired Appearance or Finish?

A hinge’s visual finish impacts aesthetics, brand perception, and durability.

Customers should indicate whether surface treatment like polishing, painting, or logo embossing is needed.

While industrial functions matter most, visible equipment—like testing chambers or trade show prototypes—may require attractive finishes. Anodized aluminum or matte black powder-coated hinges provide a sleek appearance while resisting scratches.

IHINGES also offers logo laser engraving for OEM clients wanting to build brand consistency. These details, if required, should be noted early to include in production planning.

Does the Application Require Certifications?

Industrial compliance affects both materials and processes.

Customers should specify any required certifications, such as RoHS, REACH, ISO, or UL, based on export regions or industry norms.

For example, components used in U.S. or European electrical cabinets often need UL or CE-compliant hinges. Some sectors—like medical devices or aerospace—require full material traceability and mechanical testing.

Sharing your end-use application helps manufacturers determine if standard parts meet the specs or if custom validation is necessary.

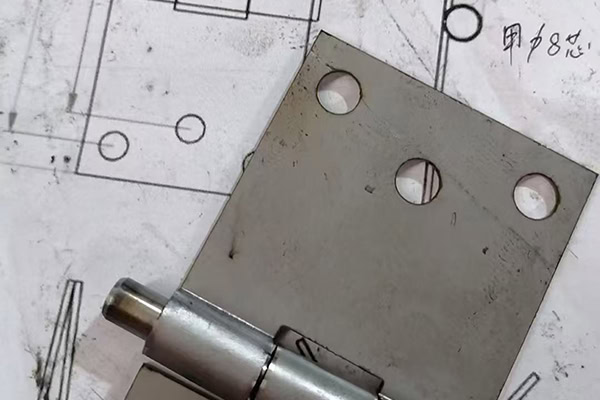

Do You Have Drawings or Design Files?

Technical drawings streamline communication and reduce ambiguity.

Providing 2D or 3D CAD files—preferably in STEP or DWG format—helps manufacturers quickly evaluate fit and recommend suitable hinges.

Even hand sketches with annotated measurements are better than verbal descriptions. Files should indicate mounting hole patterns, open angle, interference zones, and cross-sections if available.

This is especially important when matching hinges to pre-fabricated enclosures or integrating with CNC-manufactured doors. IHINGES also offers custom design support based on your provided drawings.

Conclusion

Providing clear technical details helps manufacturers deliver faster, more accurate hinge solutions.