Flat-tip hinges offer a clean appearance and enhanced durability, ideal for rugged industrial settings like equipment enclosures and panel access systems.

Flat-tip hinges are butt hinges featuring flat, cap-like tips at the ends of the hinge barrel. Common in industrial applications, they offer a minimalist look, protect hinge pins, and are available in corrosion-resistant finishes like zinc or oxide.

Flat-tip hinges play a critical role in industrial environments where equipment doors and enclosures demand precision, clean design, and long-term durability.

What Is a Flat Tip Hinge?

Flat-tip hinges, also known as button-tip hinges, feature flat, rounded caps on the ends of the hinge barrel, giving them a streamlined and professional finish.

A flat-tip hinge is a type of butt hinge with flat ends on the pin barrel, offering a compact, button-like appearance ideal for industrial machinery, electrical panels, and test chamber doors.

Dive Deeper: Structure and Function

Components and Functionality

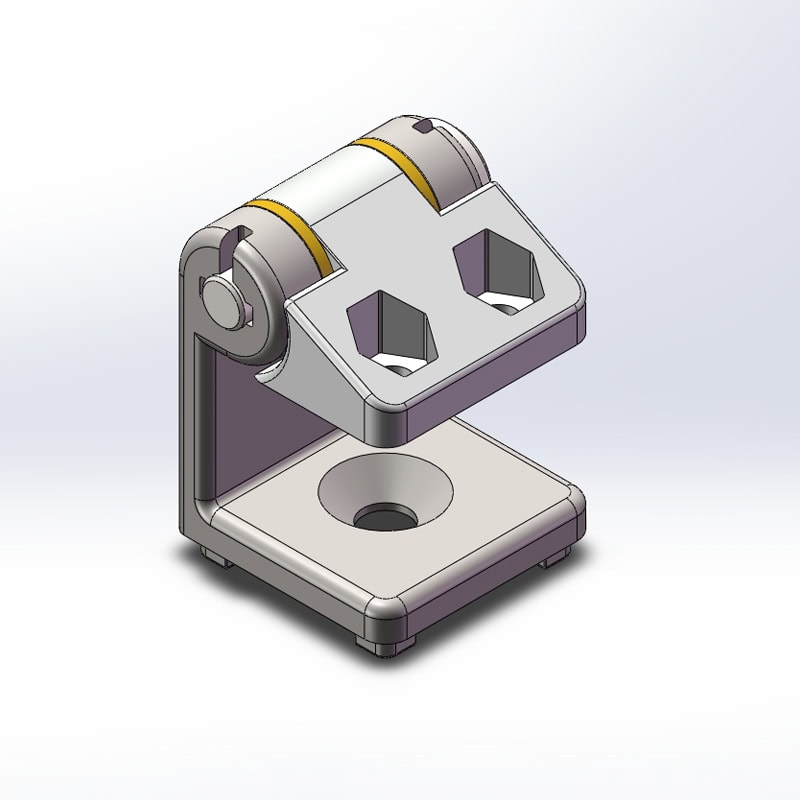

Flat-tip hinges are composed of two knuckles joined by a hinge pin. What makes them distinctive is the flat, cap-like ends that enclose the pin, protecting it from dust, moisture, and mechanical damage. This design reduces the risk of pin misalignment or failure under frequent usage—particularly important in climatic test chamber hinges and cold storage room hinges where performance is critical.

Why Industrial Sectors Prefer Flat Tips

Flat-tip hinges are ideal for use in clean, high-traffic environments. They provide a more professional appearance than exposed pins while also reducing maintenance due to their enclosed structure. When paired with corrosion-resistant hinges, flat-tip variants are excellent for environments with temperature fluctuations or moisture exposure.

| Feature | Benefit |

|---|---|

| Flat Tip Design | Protects hinge pin and internal knuckles |

| Low-Profile Aesthetics | Sleek, non-bulky finish |

| Enclosed Ends | Prevents dust and rust infiltration |

Flat Tip vs Flat Hinge – What’s the Difference?

While they sound similar, flat-tip hinges and flat (flush) hinges serve very different functions in industrial design.

Flat-tip hinges refer to the shape of the hinge ends, while flat hinges (or flush hinges) are designed to sit flush within the mounting surfaces, minimizing clearance.

Dive Deeper: Don’t Confuse the Two

Appearance vs Structure

Flat hinges are surface-mounted or recessed to sit even with the door frame or panel surface, ideal for lightweight panels or thin doors. Flat-tip hinges, however, refer strictly to the rounded flat design at the end of the hinge barrel, commonly seen in heavy-duty butt hinges used in industrial machinery or enclosures.

Use Case Differentiation

| Type | Design Characteristic | Industrial Use Case |

|---|---|---|

| Flat Hinge | Flush-mounted, compact | Light enclosures, aluminum panels |

| Flat-Tip Hinge | Decorative, end-capped pin | Electrical boxes, equipment doors |

While flush hinges prioritize space-saving, flat-tip hinges are better suited for rugged applications demanding strength and ease of replacement.

Industrial Applications of Flat Tip Hinges

Flat-tip hinges find wide usage in manufacturing settings due to their durability, clean aesthetics, and low-maintenance structure.

Flat-tip hinges are commonly used in industrial electrical enclosures, machine doors, test chambers, and heavy-duty equipment panels. Their low profile and robust construction make them suitable for repetitive-use environments.

Dive Deeper: Why Industrial Designers Choose Flat Tips

Common Applications

Flat-tip hinges are most often installed on access doors of machinery, control boxes, and storage chambers—especially where visibility and neat appearance matter. Industries such as HVAC, automotive testing, food processing, and electronic equipment manufacturing all rely on these hinges.

They are frequently combined with aluminum hinges for lightweight doors or trailer door hinges for high-mobility systems, ensuring both portability and durability.

Performance Advantages

Thanks to the added tip protection, flat-tip hinges require less maintenance and show better resistance to daily wear. Their capped ends also help reduce the ingress of contaminants—a vital feature in environments that demand cleanliness or operate under temperature control. They are often matched with Electro-Galvanized and Hot-Dipped Hinges for long-term rust protection.

| Application Type | Preferred Hinge Finish | Notes |

|---|---|---|

| Climatic Test Chambers | Oxide or zinc-plated | Anti-corrosion essential |

| Sheet Metal Enclosures | Aluminum or stainless steel | Lightweight, strong |

| Outdoor Equipment Panels | Hot-dipped galvanized | Weather and rust resistance |

Comparison: Flat Tip vs Other Hinge Tips

Different tip styles on hinges affect both form and function in industrial systems.

Flat-tip hinges are minimalistic and functional, unlike steeple tips (ornamental) or hospital tips (safety-oriented). For industrial use, flat-tip hinges offer a clean, maintenance-friendly profile.

Dive Deeper: Choosing the Right Tip for the Job

Tip Style Breakdown

While tip style may seem minor, in industrial settings, it impacts safety, maintenance, and longevity. Steeple tips, while decorative, are rarely seen in factories or workshops due to their protruding shape. Hospital tips are ideal for environments where safety and hygiene are priorities, such as medical manufacturing labs.

| Tip Type | Design Feature | Common Use |

|---|---|---|

| Flat Tip | Flat cap | Machinery, enclosures, access doors |

| Steeple Tip | Pointed decorative | Rare in industry, used for styling |

| Hospital Tip | Rounded bevel | Medical, food, and cleanroom sectors |

Practical Tip Selection

In heavy-use environments, the simplicity of flat tips reduces snag risks and makes cleaning easier. For manufacturers using special hinges or take-apart hinges, combining flat tips with modular or detachable systems further simplifies equipment assembly and maintenance.

Conclusion

Flat-tip hinges offer sleek design, high durability, and low maintenance—making them ideal for demanding industrial applications like equipment enclosures and test chamber doors.