End play in hinges is a subtle yet critical factor in industrial equipment performance and longevity.

End play is the axial gap between hinge leaves that allows smooth movement. Too much causes misalignment and noise, too little results in friction or binding. Proper end play ensures reliable, quiet hinge operation in industrial machinery.

Understanding how to control end play can significantly improve hinge design and operational reliability in industrial settings.

What Is End Play in Industrial Hinges?

End play refers to the axial movement between the hinge leaves, allowing clearance for rotation. It ensures the hinge opens and closes smoothly under load.

End play is the space between hinge knuckles that enables motion. It’s axial, not lateral, and is essential for proper hinge function.

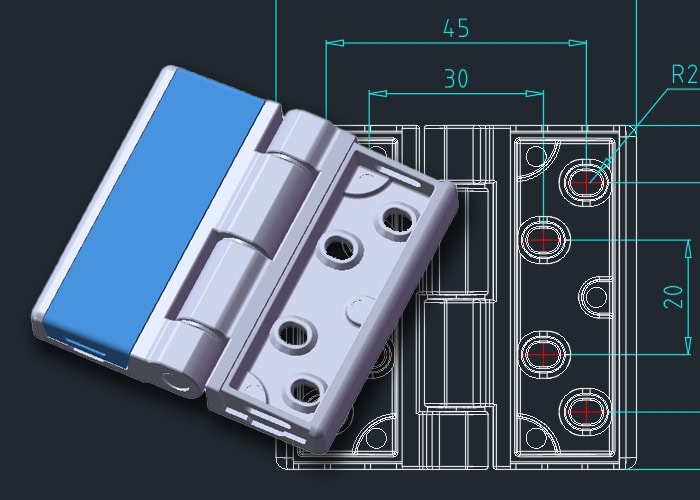

In most industrial hinges—such as butt hinges, climatic test chamber hinges, and weld on hinges—the knuckles interlock around a pin. These components need slight spacing along the pin’s axis to prevent binding. That spacing is called end play. Without it, hinges cannot operate correctly under load or over repeated cycles.

It’s important to distinguish end play from side play. End play refers to axial motion (along the hinge pin), while side play refers to lateral movement (perpendicular to the pin). Excessive side play can lead to instability, but too little end play can result in stiffness or hinge seizure—both detrimental to machinery that demands precision and durability.

Why Proper End Play Matters in Industrial Applications

Proper end play prevents excessive wear, misalignment, and operational failure. It’s essential for hinges used in heavy-duty, repetitive motion industrial environments.

Insufficient or excessive end play damages hinges and connected structures. Correct end play ensures smooth operation, alignment, and mechanical reliability.

In industrial environments, hinges are often subjected to high-frequency movements and heavy loads. Take trailer door hinges or aluminum hinges on enclosures, for instance. If end play is too large, the hinge will feel loose—causing vibration, noise, and ultimately faster wear. The connected doors or covers may rattle, shift, or misalign.

On the flip side, if end play is too tight, the leafs grind against each other. This causes heat buildup, friction, and wear—especially problematic in controlled environments like clean rooms or climate test chambers. This friction may also distort mounting points, reduce cycle life, and eventually lead to hinge failure.

How Is End Play Measured and Controlled?

End play is measured axially along the hinge pin. Manufacturers control it by adjusting knuckle spacing, pin diameter, and assembly tolerances.

End play is controlled during production through tight machining tolerances, pin fitting, and design specifications that balance clearance with support.

Precision manufacturing is key. In most industrial hinge production base facilities, CNC machining ensures knuckle lengths and pin diameters are tightly controlled. After assembly, engineers use feeler gauges or dial indicators to measure axial clearance between the knuckle sets. Ideal end play ranges from 0.005 to 0.015 inches depending on hinge type and application.

Different hinges require different levels of precision. Below is a general reference chart for common industrial hinge types:

| Hinge Type | Recommended End Play (inch) | Application |

|---|---|---|

| Weld on Hinges | 0.005 – 0.010 | Steel cabinets, trailer doors |

| Piano Hinges | 0.015 – 0.020 | Long panels, electrical box covers |

| Heavy Duty Hinges | 0.010 – 0.015 | Equipment doors, control panel access |

| Cold Storage Room Hinges | 0.008 – 0.012 | Insulated industrial refrigeration |

These tolerances ensure smooth motion without compromising alignment. Engineers must also consider operating temperature, lubrication, and material expansion in extreme environments when determining optimal end play.

End Play Requirements for Different Industrial Hinges

Different hinge types tolerate different end play. Weld-on and heavy-duty hinges need tighter tolerance, while piano hinges allow more flexibility.

Each industrial hinge design has unique end play tolerances based on load, cycle frequency, and required motion range.

End play is not a one-size-fits-all metric. Piano hinges, which run the full length of a panel or door, require more generous end play to accommodate slight inconsistencies along their length. These are used in enclosures or long electrical cabinets, where uniform motion matters more than pinpoint alignment.

In contrast, weld on hinges and climatic test chamber hinges are usually mounted on precise, heavy structures. These environments demand minimal end play to avoid vibration or sealing issues. Even slight misalignment could compromise structural integrity or thermal sealing in sensitive environments.

When sourcing or designing industrial hinges, engineers must evaluate:

-

Load-bearing capacity

-

Environmental factors (dust, temperature, moisture)

-

Frequency of use

-

Hinge material and finish

Selecting the right hinge design with the appropriate end play tolerance is essential for long-term performance and reliability.

End Play Troubleshooting in Installed Hinges

End play issues show as door misalignment, noise, or binding. Check pin looseness, knuckle spacing, and wear to diagnose problems.

Check end play during hinge inspection to identify abnormal movement, friction, or wear. Adjust or replace hardware as needed.

In the field, hinge end play problems often show up as:

-

Rattling noises during vibration

-

Doors not sitting flush when closed

-

Increased resistance when opening or closing

-

Knuckle damage or visible spacing irregularities

To fix excessive end play, one might:

-

Insert precision washers or spacers

-

Replace worn pins with oversized variants

-

Replace hinges with those of tighter machining tolerances

For insufficient end play, it’s often better to replace the hinge entirely. In many cases, tight clearances cannot be adjusted post-manufacture. Using hinges designed for your operating conditions—such as marine hinges for corrosion resistance or cam rise hinges for self-closing features—will ensure greater durability and performance.

Regular inspection and maintenance help prevent long-term damage from improper end play, saving time and cost in industrial operations.

Conclusion

Controlling end play is key to hinge performance and durability in industrial environments.