Full mortise hinges are critical to maintaining door integrity and performance in industrial environments.Full mortise hinges are embedded into the door and frame, providing seamless support, reducing wear, and improving aesthetics. Their robust construction and high load capacity make them ideal for heavy-duty industrial doors where long-term performance and security are essential.

A proper hinge choice prevents costly misalignment and ensures smooth industrial operations.

What Are Full Mortise Hinges and How Do They Work?

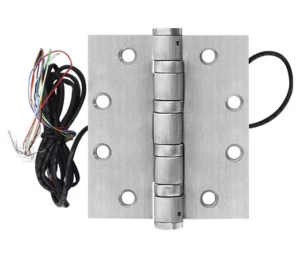

Full mortise hinges are designed to fit flush into a recess cut on both the door and the frame, providing a clean, tamper-resistant installation. This design not only enhances aesthetics but also delivers higher structural integrity, making them ideal for high-performance industrial environments.

Full mortise hinges are recessed into the door and frame to allow smooth, unobtrusive operation. They are preferred in industrial and commercial settings due to their strength, durability, and security advantages.

Recessed Design for Structural Integrity

Unlike surface-mounted options, full mortise hinges are barely visible when the door is closed. This hidden design minimizes the exposure of mechanical components, reducing the risk of tampering or damage, particularly in security-sensitive applications such as control cabinets and climatic test chambers.

The recessed structure also allows for even weight distribution across the hinge leaf, which prevents sagging over time. This is crucial for facilities that use heavy duty hinges on oversized or high-use doors, such as those found in industrial ovens or cleanroom environments.

Ideal for Metal Doors and High Traffic Zones

Full mortise hinges are often applied to metal doors in commercial and industrial facilities. Their capacity to withstand high-frequency operation without losing alignment makes them an indispensable part of long-lasting industrial door systems. They also work seamlessly with trailer door hinges or heavy-duty enclosures requiring superior load-bearing capabilities.

Why Full Mortise Hinges Are Ideal for Industrial Use

Industrial environments demand performance hardware that supports daily abuse. Full mortise hinges provide enhanced mechanical strength and keep doors operating smoothly in high-traffic areas.

Full mortise hinges prevent misalignment and wear under constant use, making them ideal for industrial applications such as manufacturing plants and logistics centers.

Resilience Under Daily Operation

In plants, cold storage rooms, and cleanrooms, doors may open hundreds of times per day. Inferior hinges often sag or loosen, compromising operational efficiency and safety. Full mortise hinges combat this by distributing stress uniformly across the mounting area, thus reducing hardware fatigue.

They are particularly useful when paired with other functional hinge types such as cam rise hinges that help raise the door slightly when opening, reducing floor drag and wear.

Common in Sheet Metal Fabrication Applications

Many industrial sheet metal manufacturers use full mortise hinges on electrical cabinets, test equipment doors, and heavy-duty access panels. Their flush design not only enhances security but also provides better support for doors with integrated locking systems or airtight seals.

Heavy-Duty Construction and Load Capacity

Heavy-duty full mortise hinges are engineered to support extreme weights, often exceeding 8,000 lbs, and are built for applications with oversized or thick industrial doors. Heavy-duty full mortise hinges support large industrial doors, often handling over 8,000 lbs, ensuring safe, long-term door function under heavy loads.

Engineered for Massive Doors

Whether in industrial refrigeration units or freight facility doors, full mortise hinges come with precision machining and hardened steel pins to manage extreme pressure. Some models, like the McKinney 5BB1, are tested to withstand years of wear under consistent abuse.

These hinges are especially important for large installations where door misalignment could result in functional failure or safety risks. They also provide vertical and radial load support, ensuring long-term alignment.

Examples of Use in Extreme Load Scenarios

-

In constant temperature testing chambers, doors are often layered with insulation, increasing the load significantly.

-

In marine environments, full mortise marine hinges are necessary to withstand salt, wind, and vibration while still handling significant weight.

Material Options and Corrosion Resistance

Choosing the right material enhances hinge performance, especially in harsh or corrosive conditions. Stainless steel variants offer superior durability and rust resistance. 304 and 316 stainless steel full mortise hinges offer excellent corrosion resistance for humid, coastal, or chemically exposed environments, ensuring long-term performance.

Material Comparison by Application

| Material | Strength | Corrosion Resistance | Typical Use Cases |

|---|---|---|---|

| Carbon Steel | High | Low | Indoor, general industrial doors |

| 304 Stainless Steel | High | Medium-High | Kitchens, humid factories, cleanrooms |

| 316 Stainless Steel | High | Very High | Marine, chemical, salt-laden environments |

304 SS offers great protection against general corrosion and is common in food and medical environments. 316 SS, however, is the top choice for marine and high-chemical exposure zones due to its molybdenum content.

Cost vs. Performance Considerations

While stainless steel options are more expensive, they reduce maintenance costs over time. For high-risk environments or government/military applications, investing in high-grade hinges pays off in reliability and safety.

Full Mortise vs. Surface Mounted Hinges

The difference between surface-mounted and full mortise hinges affects both the door appearance and its mechanical reliability. Full mortise hinges are recessed, making them more secure and aesthetically cleaner than surface-mounted hinges, which are easier to install but less robust.

Why Flush Installation Matters

Full mortise hinges sit within the edge of the door and frame, hiding hardware from view. This makes them harder to tamper with and ideal for environments where appearance and security are important.

In contrast, surface-mounted hinges are faster to install and replace but compromise on security and wear-resistance over time.

Practical Use Cases

-

Full mortise: Test chambers, stainless steel industrial doors, medical facility doors

-

Surface-mounted: Lightweight storage doors, temporary structures, maintenance panels

Conclusion

Full mortise hinges offer unmatched strength, security, and long-term performance for industrial and commercial doors. Their flush installation, high load capacity, and corrosion-resistant materials make them the hinge of choice for demanding environments.