Industrial hinge manufacturing demands materials and tooling that can meet rigorous standards of strength, precision, and cost-efficiency.

Cast iron molds are used in hinge production due to their durability, thermal stability, and ability to maintain dimensional accuracy during high-volume casting—ideal for manufacturing heavy-duty and precision hinges in industrial settings.

To understand why cast iron molds are favored in hinge manufacturing, let’s explore their unique characteristics and compare them with other mold types.

What Are Cast Iron Molds and Their Key Properties?

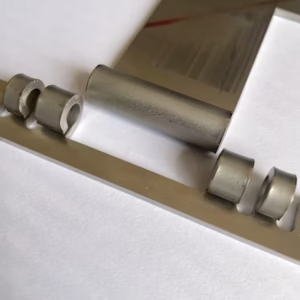

Cast iron molds are tooling components made from specific grades of cast iron, such as gray iron or ductile iron, designed to shape molten metal into precision parts. These molds are widely used in the manufacturing of industrial components requiring strength, consistency, and resistance to deformation under high temperatures.

Cast iron molds provide high hardness, excellent wear resistance, and stable dimensional control, making them ideal for repeated use in industrial hinge casting processes.

Cast iron, as a mold material, offers unique metallurgical properties that suit long production cycles. There are several cast iron types, including gray iron, ductile iron, white iron, malleable iron, and compacted graphite iron. Each type exhibits specific properties that impact the mold’s performance.

| Type of Cast Iron | Key Strength | Application Example |

|---|---|---|

| Gray Iron | Excellent vibration damping | Mold bases, machinery casings |

| Ductile Iron | High ductility & toughness | Heavy-duty hinges and truck parts |

| White Iron | High hardness | Abrasion-resistant surfaces |

| Malleable Iron | Moderate toughness | Complex-shaped hardware components |

| CGI | Strength + machinability | Automotive, industrial tooling |

These mechanical traits enable cast iron molds to produce parts such as Electro-Galvanized and Hot-Dipped Hinges with consistency and structural integrity over extended manufacturing runs.

Why Use Cast Iron Molds for Industrial Hinges?

Industrial hinges are often exposed to extreme mechanical stress, vibration, or temperature shifts. Cast iron molds enable manufacturers to produce robust, high-precision parts suitable for demanding applications, such as equipment enclosures or transportation hardware.

Cast iron molds are used because they enable the mass production of complex, structurally sound industrial hinges like Adjustable friction hinges, which require high mechanical stability and dimensional accuracy.

Unlike aluminum or steel molds, cast iron tooling can maintain tight tolerances under repeated thermal cycles, which is especially valuable when casting metals like zinc or aluminum alloys into detailed hinge forms. In industries such as cold storage or transportation, hinges like Heavy Duty Detachable Barrel Hinges must maintain alignment under load. Cast iron molds ensure that such precision is maintained throughout each part produced.

Moreover, cast iron molds support post-processing treatments like grinding, drilling, and coating, which is critical when manufacturing friction-control or torque-adjustable hinges.

Limitations of Cast Iron Molds in Industrial Manufacturing

Although cast iron molds have many benefits, they also pose several limitations in specific scenarios. These disadvantages must be considered during project planning.

Cast iron molds are brittle, heavy, and more costly to repair or modify than aluminum or steel tooling, which makes them less ideal for low-volume or complex geometry parts.

Due to their high carbon content and crystalline structure, cast iron materials are inherently brittle. While excellent for compression loads, cast iron cannot absorb tensile or shock forces well. This makes cast iron molds vulnerable to cracking under improper handling or in cases where the design must frequently change.

For example, if a company is prototyping a new Heavy Duty Truck Door Hinge design with many revisions, cast iron molds may be too inflexible and expensive for iterative updates. In such cases, softer tool steels or modular die systems are preferred.

Another factor is weight—cast iron is considerably heavier than aluminum or magnesium alloys, increasing logistical and setup costs in high-volume plants. Despite these drawbacks, cast iron molds remain valuable for high-precision, high-durability industrial hinge production where design changes are minimal.

Comparison: Cast Iron Molds vs Other Manufacturing Methods for Hinges

Selecting the right production method involves balancing design complexity, production volume, cost, and mechanical requirements. Cast iron molds are particularly strong in scenarios requiring long-term production and part uniformity.

Compared to stamping or die-casting, cast iron mold casting provides superior mechanical strength and repeatability for large, structurally complex industrial hinges.

| Manufacturing Method | Strength | Complexity | Surface Finish | Tooling Cost | Best Suited For |

|---|---|---|---|---|---|

| Cast Iron Molding | Very High | Moderate | Medium | Medium-High | Heavy duty hinges, friction parts |

| Stamping | Low-Medium | Low | High | Low | Sheet metal panels, enclosures |

| Die Casting | Medium | High | High | High | Decorative or complex small hinges |

| CNC Machining | Very High | Very High | Very High | Very High | Prototypes, aerospace-grade hinges |

| MIM | High | High | High | Medium | Miniature or intricate hinges |

Hinges like Wide-throw hinges or Heavy-duty long hinges, which are typically used in outdoor industrial enclosures or machinery doors, benefit significantly from the strength and dimensional control that cast iron molds offer. These methods also ensure excellent performance under repeated mechanical load or environmental exposure.

Conclusion

Cast iron molds offer strength, thermal stability, and consistency—making them ideal for industrial hinge manufacturing, especially for high-performance and high-volume applications.