Ordinary hinges often corrode, loosen, and fail under constant marine stress—causing safety hazards, water leakage, and operational downtime. The solution lies in using heavy duty flush hinges, specifically engineered for strength, corrosion resistance, and smooth integration into marine structures.

Heavy duty flush hinges are essential for ships and yachts because they combine corrosion resistance, load-bearing strength, and a flush-mounted design that prevents tripping hazards and improves marine safety and durability.

In marine manufacturing, the right hinge is more than hardware—it’s a structural component.

What Are Heavy Duty Flush Hinges?

Heavy duty flush hinges are precision-engineered hinges designed to sit level with the surface, providing a clean, unobtrusive finish. Unlike standard butt hinges, they don’t protrude from the door or hatch, preventing interference and enhancing both safety and appearance. The “heavy duty” designation refers to their ability to withstand high loads, repetitive motion, and extreme conditions—qualities crucial for marine applications.

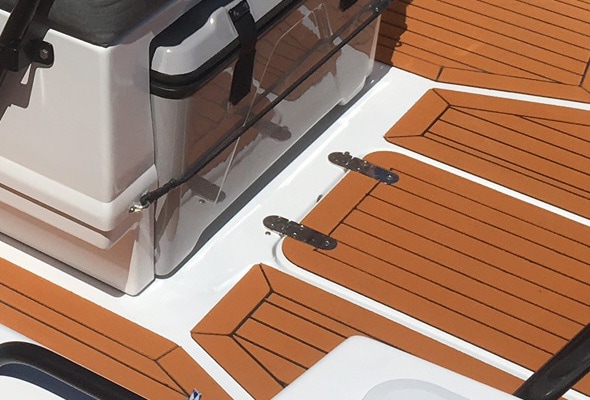

In shipbuilding and yacht fabrication, these hinges are commonly installed in watertight doors, deck hatches, and access compartments. They’re crafted from marine-grade materials like 316 stainless steel or anodized aluminum, ensuring durability even under heavy vibration and saltwater exposure. Similar to heavy duty exterior hinges used in industrial environments, marine-grade flush hinges focus on long-term reliability rather than decorative aesthetics.

Marine Environments Demand Corrosion Resistance

The ocean is an unforgiving environment for metal components. Constant exposure to saltwater and humidity accelerates oxidation and rust, leading to hinge failure if unsuitable materials are used. Heavy duty flush hinges made from 316 stainless steel or specialized anti-corrosion coatings resist these effects far better than standard hardware.

Corrosion resistance isn’t just a matter of longevity—it’s also a matter of safety. A rusted hinge can seize or snap, compromising watertight integrity or hatch operation. That’s why many manufacturers prefer Heavy Duty Continuous Hinges in high-exposure zones, ensuring consistent torque and smooth movement across large panels. By choosing corrosion-resistant hinges, shipbuilders reduce maintenance costs and extend vessel service life.

Flush Design Ensures Safety and Space Efficiency

Space is always limited aboard ships and yachts, where every inch of deck and cabin area must be maximized. Flush-mounted hinges eliminate sharp edges and protrusions that can snag ropes, clothing, or equipment—reducing tripping hazards and improving onboard safety.

In luxury yachts, this design also enhances visual appeal. Doors and hatches close seamlessly, preserving the smooth contours of high-end interiors. But the benefit isn’t only aesthetic: flush hinges maintain structural alignment even in tight spaces, avoiding deformation caused by repeated pressure or vibration. This feature distinguishes them from surface-mounted alternatives like Adjustable friction hinges, which are more suited to industrial or electrical enclosures rather than marine applications.

Heavy Duty Construction Supports Structural Integrity

Marine doors and hatches endure intense mechanical stress from wave impact, vessel movement, and frequent usage. Heavy duty flush hinges incorporate reinforced knuckles, thick hinge leaves, and precision-ground pins to handle these loads without deformation. Many designs feature non-removable pins or thrust washers that resist shear forces and vibration fatigue.

The mechanical integrity of these hinges contributes directly to vessel safety. Whether supporting a 50-kg hatch cover or a thick aluminum access panel, they prevent misalignment and ensure smooth operation under dynamic loads. Heavy duty flush hinges are often tested to meet industrial standards similar to those used for offshore and naval hardware.

Long-Term Value and Reduced Maintenance

In a marine environment, every component is subject to wear. Heavy duty flush hinges minimize the need for maintenance by using self-lubricating bearings and corrosion-resistant finishes. This not only reduces downtime but also extends the replacement cycle—critical for commercial vessels and charter operations.

Maintenance efficiency translates into cost savings. Since flush hinges are built for endurance, shipowners avoid frequent overhauls or emergency repairs at sea. Their ability to withstand vibration and motion without loosening or binding makes them a reliable choice for long-term maritime applications.

Where Are Heavy Duty Flush Hinges Commonly Used on Vessels?

Applications include watertight doors, deck lids, engine hatches, and storage compartments. On luxury yachts, they’re also used in concealed cabinetry and custom access panels where both functionality and design aesthetics matter.

Different hinge types serve different marine needs: wide-throw hinges allow greater door clearance, friction hinges enable controlled opening angles, and heavy-duty long hinges provide added stability for oversized panels. By matching hinge type to function, shipbuilders ensure optimal balance between strength, movement, and safety.

Conclusion:

Heavy duty flush hinges are essential to the safety, durability, and performance of ships and yachts—combining corrosion resistance, structural strength, and flawless integration for reliable marine operation.