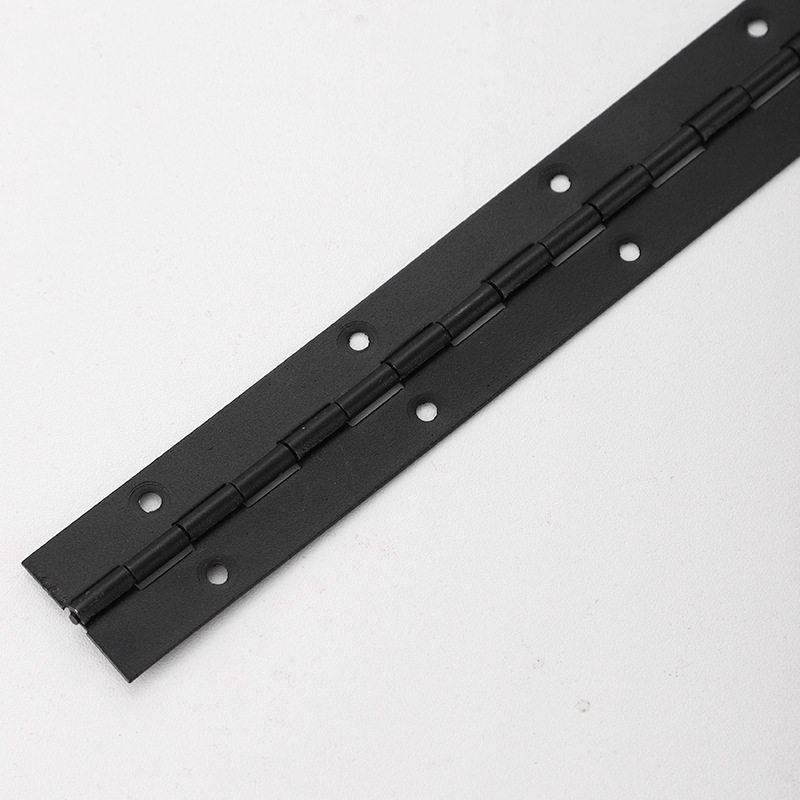

Piano hinges, commonly renowned for their sturdy and continuous design, have found their way into various applications beyond the eponymous musical instrument. When colored black, these hinges offer both aesthetic appeal and functional utility, making them incredibly versatile.

Black piano hinges, aside from their obvious appeal for aesthetic purposes, are highly sought after due to their durability, discreet appearance, and adaptability in a range of uses outside of furniture and decor.

By delving deeper into the realm of these hinges, we can understand their significance and discover applications we may never have considered.

History of the Piano Hinge

The piano hinge, despite its name, wasn’t solely designed for pianos. Its inception dates back to a time when continuous, long hinges were needed for various applications, from aircrafts to toolboxes. Over time, the name ‘piano hinge’ became popular because of its frequent use in piano lids, offering both support and flexibility.

As for the black coloration, it was introduced to match darker materials and to offer a more sleek and understated appearance. This finish quickly became a favorite among industries looking for a functional hinge that also provided a touch of elegance.

Manufacturing Process

When manufacturing piano hinges, precision is paramount. These hinges are typically crafted from a single, long piece of metal, ensuring a continuous hinge pin and uniform leaf structure. The black hue is typically achieved through a powder coating process.

Powder coating is preferred due to its durability and ability to withstand various conditions without chipping or fading. This process involves applying a dry powder to the metal surface and then heating it to form a protective layer. The result is a sleek, smooth, and resilient black finish.

Applications in the Transportation Industry

One might be surprised to learn that black piano hinges play a pivotal role in the transportation industry. Aircraft doors, automobile glove compartments, and compartments in trains all utilize these hinges for their durable and consistent movement.

Because these hinges spread the load across a broader surface area, they are particularly useful in vehicles where consistent movement and heavy usage can wear out traditional hinges. The black finish adds an element of sophistication while remaining unobtrusive.

Durability and Maintenance

Black piano hinges are lauded for their durability, primarily due to their continuous design which distributes weight evenly. This even distribution reduces the chances of misalignment and wear, prolonging the hinge’s lifespan.

Maintenance is relatively simple. Regular dusting and occasional lubrication are sufficient to ensure a smooth operation. The black powder coating is robust, resisting rust and corrosion, meaning these hinges remain functional and aesthetically pleasing for years.

Environmental Benefits

In today’s age of sustainability, it’s essential to consider the environmental impact of any product. Black piano hinges, when crafted from recycled materials, offer an eco-friendly alternative to traditional hinges.

Moreover, the powder coating process is environmentally friendly compared to other methods. It emits fewer volatile organic compounds (VOCs), and the majority of overspray can be reclaimed and reused, reducing waste.

Conclusion

Black piano hinges, while a niche product, have found their footing in various industries due to their durability, aesthetic appeal, and versatility. From their history to their environmental impact, understanding these hinges offers insight into their widespread use and highlights their significance beyond the realm of pianos.

You might also be interested: