In the vast world of machinery, hinges might appear as just another component. Yet, their significance is undeniable. Their adaptability and role in ensuring smooth machinery operation often go unnoticed.

Undoubtedly, industrial hinges can be custom-fabricated to cater to specific operational demands. Their bespoke nature ensures they meet diverse industry standards, subsequently elevating the performance and longevity of the machinery they serve.

With countless industries relying on hinges, understanding the customization of these components becomes paramount. Such knowledge empowers industries to optimize their machinery’s capabilities fully.

The Need for Customization

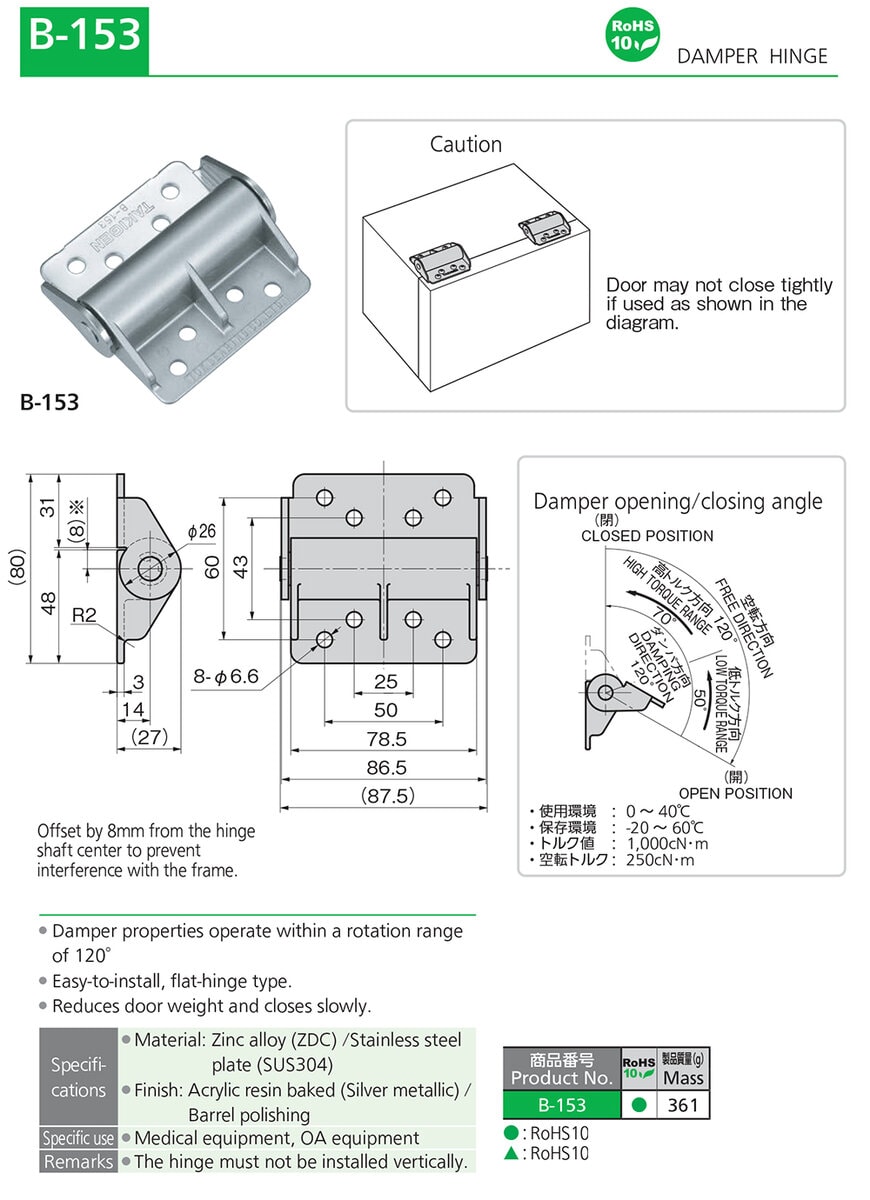

Every industry comes with its unique set of challenges. These challenges dictate specific machinery requirements. Hence, a generic hinge might not cater to the nuanced needs of all. For example, a cold storage unit would need hinges that can withstand low temperatures, while a furnace would require heat-resistant ones.

Custom hinges, therefore, fill this gap. They’re meticulously crafted to cater to the distinct demands of each machinery, ensuring that the equipment performs optimally and lasts longer.

Benefits of Custom-Made Hinges

At first glance, choosing a custom-made hinge may seem like a minor decision. However, this choice can dictate the overall functionality of a piece of machinery. Tailored hinges ensure seamless operation, offering perfect fit and resistance against specific environmental challenges, enhancing the machinery’s lifespan.

Moreover, they play a pivotal role in reducing frequent maintenance needs. When a hinge fits perfectly, there’s minimal wear and tear, ensuring that the machinery functions smoothly for extended periods.

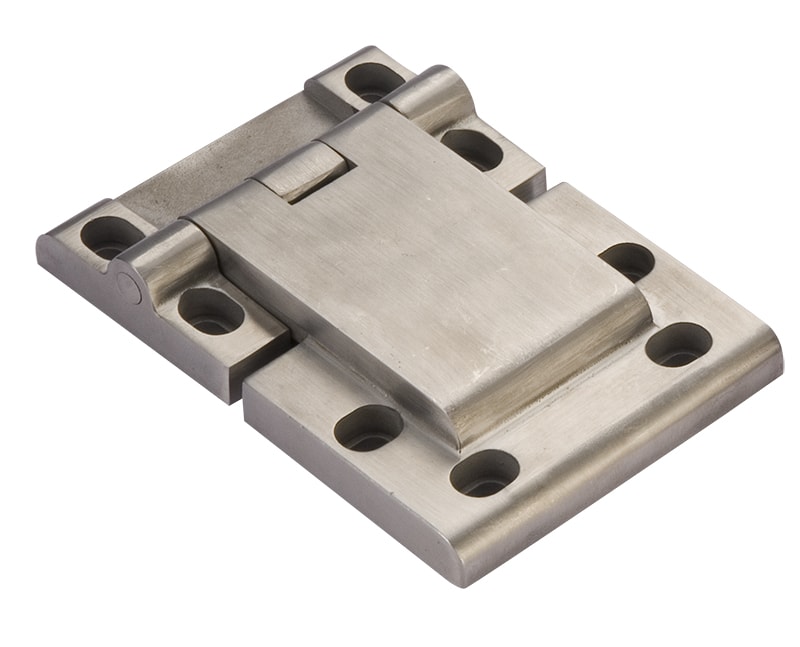

Material Choices and Their Impact

The choice of material for a hinge can be a game-changer. Materials like stainless steel are renowned for their durability, while others like brass are celebrated for specific properties, such as non-sparking.

Selecting the right material based on the machinery’s operational environment is crucial. It determines the hinge’s longevity, resistance to various elements, and overall performance.

Load-Bearing Capacity

Not all hinges are created equal, especially when it comes to bearing weight. Custom hinges can be designed to withstand specific pressures, ensuring the machinery’s safety and consistent operation.

This adaptability ensures that the hinge doesn’t give way under intense pressure or weight. A tailored hinge, in this context, offers reliability, especially in heavy-duty industrial applications.

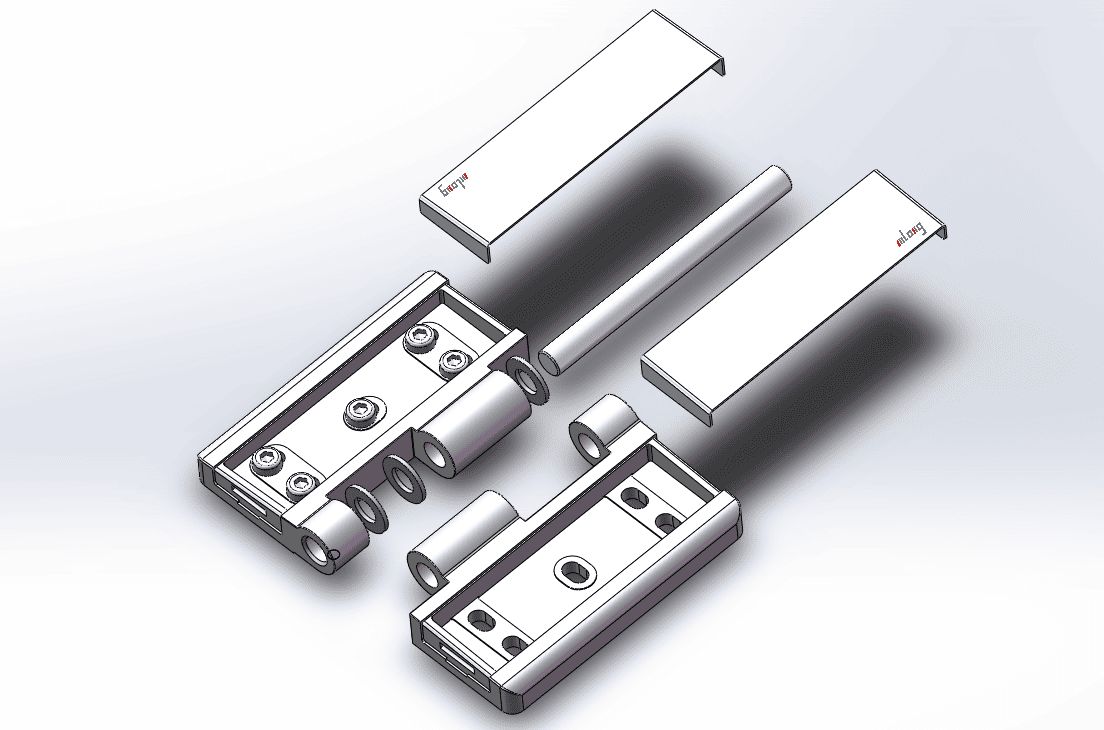

Hinge Designs and Their Applications

Hinges come in diverse designs, each catering to a unique operational need. The traditional pin and knuckle design is widespread, but there are myriad others, such as continuous hinges or pivot hinges.

Understanding and choosing the right design based on machinery requirements can be instrumental. It determines how the equipment operates, its range of motion, and its overall efficiency.

The Role of Surface Treatments

Hinges often undergo surface treatments to bolster their durability and functionality. Processes like galvanizing or chrome-plating enhance the hinge’s resistance to external factors.

Such treatments not only extend the hinge’s lifespan but also ensure that it remains functional across various challenging operational environments, from extreme temperatures to corrosive atmospheres.

Cost Implications of Custom Hinges

While custom hinges might seem pricier initially, their long-term benefits often outweigh the initial investment. Their bespoke nature ensures a perfect fit, leading to reduced maintenance and extended machinery life.

Investing in custom-made hinges often translates to cost savings in the long run. The reduced need for frequent replacements and repairs compensates for the initial higher expenditure.

The Process of Customization

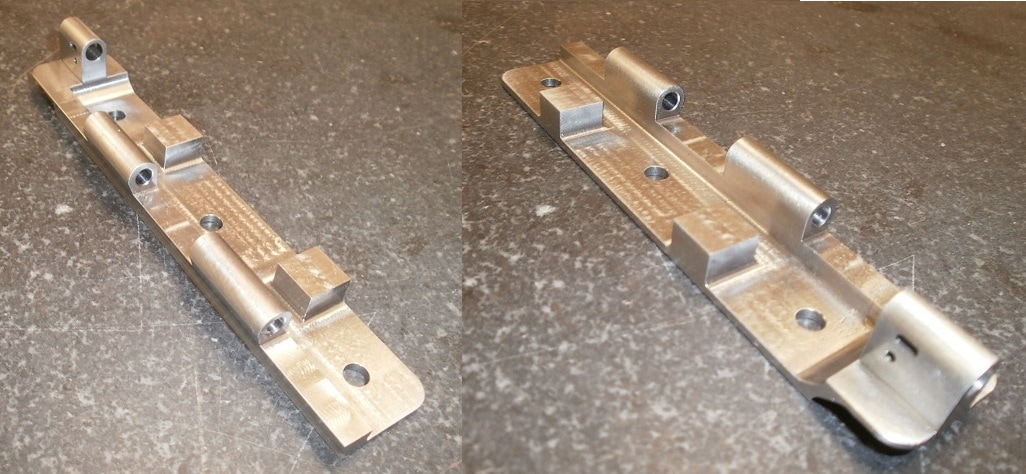

Customization is a meticulous journey from conceptualization to realization. It begins with a comprehensive understanding of the client’s specifications, transitioning to design blueprints, prototype development, rigorous testing phases, and finally, mass production.

This intricate process ensures that the end product seamlessly integrates with the machinery, enhancing its performance and durability.

Conclusion

Custom-made industrial hinges are indispensable for many industries today. Their tailored nature ensures machinery’s optimized performance, safeguarding hefty industrial investments.

IHINGES prides itself as a frontrunner in the industrial hinge manufacturing domain. Our commitment to quality, combined with competitive pricing, sets us apart. We specialize in customizing hinges to align perfectly with your equipment. For unmatched quality at favorable rates, don’t hesitate to ask us for a quote.

You might also be interested: