Choosing the right marine hinge is crucial to ensure longevity, safety, and reliable performance in harsh sea environments.

To choose the right marine hinges for your boat, focus on material quality (preferably 316 stainless steel), corrosion resistance, load capacity, hinge type, and environmental durability. Match the hinge style to its application—hatch, locker, or access panel—and always confirm sizing and installation compatibility for long-term performance.

Want your boat’s hardware to survive years of salt, motion, and wear? Let’s dive into what really matters when sourcing marine hinges.

Material Selection for Marine Hinges

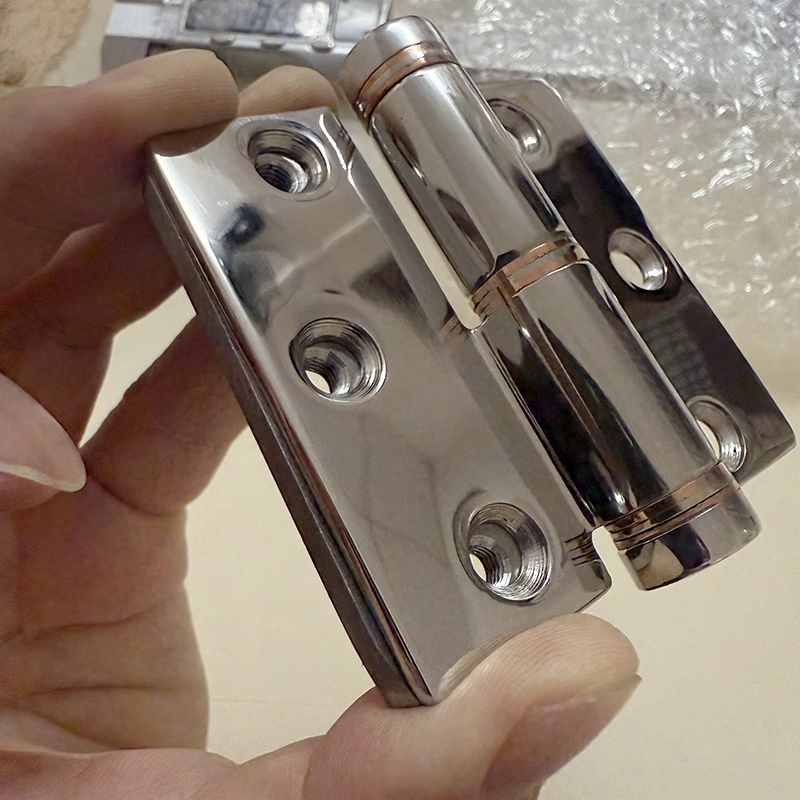

Marine hinge materials determine corrosion resistance, strength, and service life. 316 stainless steel is the most corrosion-resistant material for marine hinges, offering superior protection in saltwater conditions compared to 304 stainless or brass. Heavy-duty marine environments like offshore platforms or ship engine compartments demand hinges that resist pitting, rusting, and surface wear. For high-salinity zones or tropical climates, 316 Stainless Marine Friction Hinges are the top-performing option.

High-load applications may also require heavy duty weld on hinges, especially when permanent, vibration-resistant attachment is needed on steel boat hulls or armored marine doors. Brass or zinc alloys may look attractive but lack the endurance and corrosion resistance required in industrial marine contexts.

Manufacturers and procurement teams sourcing for long-term durability in boat manufacturing or repairs should always verify the material grade, finish, and corrosion resistance specs before purchase.

Types of Marine Hinges and Their Applications

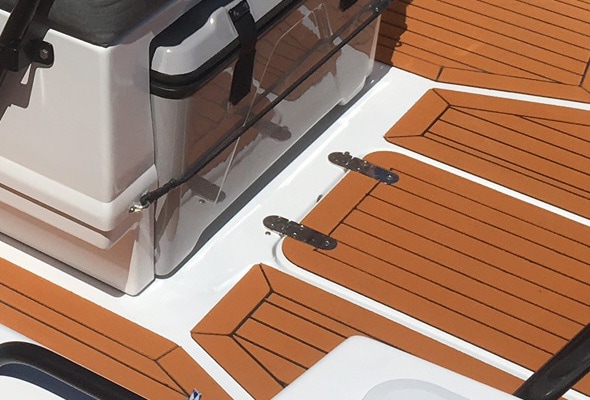

Marine hinges vary by application, shape, and load demands. The most common marine hinge types include butt hinges, piano (continuous) hinges, strap hinges, and take-apart hinges, each suited for different components like hatches, cabinets, or doors. For example, Heavy Duty Continuous Hinges are ideal for long engine room access panels, offering full-length support and even weight distribution. For watertight compartments, concealed and compression hinges may be preferable.

In highly dynamic marine applications, friction hinges with adjustable torque are becoming popular. These help hold open compartments without gas struts, crucial for safety and functionality in rough seas. Use of Adjustable friction hinges can also reduce maintenance since they eliminate moving gas cylinders or latches.

Each hinge type must be matched with its mechanical function and environmental demand. B2B buyers in the marine industry should confirm hinge drawings, load specs, and mounting options before committing to bulk orders.

Load-Bearing Capacity and Durability

Load capacity directly impacts the hinge’s reliability and service life. Marine hinges must handle both static and dynamic loads, especially on moving vessels exposed to wave impact, wind, and shifting cargo. Hinges on hatches, doors, or access covers are often exposed to continuous vibration and must remain intact without deformation or seizing.

Engine compartment doors, for example, may benefit from staked hinge designs or ball bearing assemblies to prevent fatigue and metal wear. Applications requiring constant repositioning—like adjustable panels or inspection doors—are best equipped with Adjustable Torque Stainless Steel Hinges that maintain position under motion stress.

To ensure durability, manufacturers and buyers must consider the hinge’s internal components (pins, knuckles, washers), material fatigue thresholds, and how movement impacts hinge alignment over time. These insights are critical when sourcing hinges for military, offshore, or industrial marine applications.

Load Consideration Table

| Application Area | Recommended Hinge Type | Notes |

|---|---|---|

| Hatch Cover | Heavy Duty Piano Hinge | Distributes weight across full opening |

| Engine Compartment | Ball Bearing Butt Hinge | Reduces wear from frequent access |

| Watertight Locker Door | Compression Latch Hinge | Ensures tight seal |

| Equipment Panel | Adjustable Friction Hinge | Holds open under vibration |

Corrosion Resistance and Environmental Suitability

Marine hinges must withstand saltwater, UV rays, and constant humidity. Corrosion resistance is non-negotiable for marine hardware, and the best-performing options are electro-polished or passivated 316 stainless steel hinges. For industrial-scale marine applications—such as climate testing chambers or power systems—hinges with additional marine coatings or sealed joints are preferred to ensure performance in high-moisture zones.

Avoid chrome-plated or painted hinges unless the coating is specified for marine-grade use. Electro-Galvanized and Hot-Dipped Hinges can be considered for freshwater or interior compartments, but they typically fall short in ocean environments.

Custom marine applications, like aluminum vessel lockers or electrical cabinet enclosures, may require specialized sealing or hidden installations. In such cases, weather-sealed gaskets or use of Invisible Hinges in waterproof housing designs could be valuable for preventing corrosion intrusion and improving aesthetics.

Measuring and Sizing Hinges Correctly

Precision in measurement prevents costly installation errors. When replacing or installing marine hinges, always measure leaf width, pin diameter, mounting hole centers, and hinge length. Use calipers and templates to ensure compatibility, especially when retrofitting industrial marine hardware. Always account for expansion due to heat and movement when selecting fit.

Large hatches or access doors should use Heavy-duty long hinges for proper alignment and even weight distribution. Ensure you match the hinge’s open angle and rotation limit with the door or hatch design.

Procurement professionals should request 2D drawings or 3D CAD files from the supplier to check specifications and streamline installation planning. A small measurement error can lead to mechanical misalignment, compromised waterproofing, or premature hinge wear.

Certifications and Compliance Considerations

Certifications reduce risk and ensure consistent product quality. Marine hinges should comply with certifications such as ISO 9001, RoHS, REACH, or MIL-STD, especially in regulated environments like commercial shipping, defense, or offshore installations. Certification ensures material quality, performance standards, and production consistency.

Procurement engineers sourcing from China or other offshore manufacturers should demand test reports, corrosion resistance data, and certificates of origin. This is especially important for Electrical Panel Hinges or hardware used in fire-rated or pressure-sealed enclosures.

A reliable supplier should also offer traceability documents, batch testing records, and packaging standards suitable for export shipping.

Customization Options and Supplier Capabilities

Customization unlocks design flexibility and branding control. Industrial buyers benefit from manufacturers that can offer logo engraving, hinge style modification, and full CAD drawing support. For example, customizing Butt Hinges for Doors with specific mounting holes or surface finishes can streamline installation and increase brand value.

If you’re sourcing for multiple enclosure sizes or different compartment types, select a supplier who understands technical drawings and responds quickly with design revisions. Poor communication is a frequent pain point for buyers—especially those needing quick prototyping or hinge adaptation.

Suppliers like IHINGES offer 3D design previews and can produce rare hinge types for specialized industrial marine projects. From Replace Industrial Door Hinges to unique mounting bracket systems, a factory with full production capacity ensures better lead time control and cost-efficiency.

Conclusion

Choosing the right marine hinge means aligning material, type, durability, and compliance to your specific industrial needs. Always consider application, load, and supplier capabilities when making sourcing decisions.