The complexity of producing heavy-duty butt hinges can vary depending on the production process. Our common production processes are stamping and casting. The choice of the process can be determined by the customer’s requirements and the materials used.

This article will introduce you to the production process of heavy-duty butt hinges and how each component of the hinge is produced.

What is a heavy-duty butt hinge?

Heavy-duty butt hinges are a type of butt hinge with a strong load-bearing capacity. The structure is simple and consists of two hinge blocks and a shaft. Its strong load-bearing properties are characteristic of this type of hinge. It is both heavy-duty hinges and butt hinges. It is mainly used on heavier doors to connect the door to the door frame, as well as to carry the weight of the door.

Heavy-duty butt hinges are available in different materials, either iron, stainless steel, or zinc alloy, and the different materials affect the production process of the hinge to a certain extent. For example, the iron plate material can only be used in the stamping process, while the zinc alloy material can only be used in the die-casting process.

Heavy-duty docking hinges are characterized by strong load-bearing, so their axle requirements are relatively high, and we must use stainless steel axles to achieve the required load-bearing effect. Or use a better material to produce. Because the weight of the door will be mainly applied to the shaft and the direction of the force is often unfavorable to the shaft center.

The production process of heavy-duty butt hinges

There are two main production processes for heavy-duty butt hinges, stamping, and casting.

The stamping process is a metal processing method, which is based on the characteristics of plastic deformation of metal, using dies and stamping equipment to apply pressure to the sheet metal so that the sheet metal will be deformed or separated. In this way, stamped parts with a certain shape, size, and performance can be obtained.

The stamping process is a processing method with high productivity and low material consumption. It is easy to operate the process and does not require the operator to have a high level of craftsmanship. The stamped parts generally do not require secondary processing and have high dimensional accuracy.

As the stamping parts are made of sheet metal material, it has the better surface quality and can facilitate the subsequent surface treatment process. And the cost of products produced by the stamping process is low.

Die casting is a metal casting process characterized by the use of a mold cavity to apply high pressure to the molten metal. The mold is usually machined from a stronger alloy, a process somewhat similar to injection molding.

Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, either a cold chamber dies casting machine or a hot chamber die casting machine is used.

The die-casting process can produce parts with high dimensional accuracy, also depending on the materials used. The casting surface is smoother than other casting processes, and it allows direct casting of internal structures, allowing the production of products with complex structures. This feature is more advantageous than the products of the stamping process.

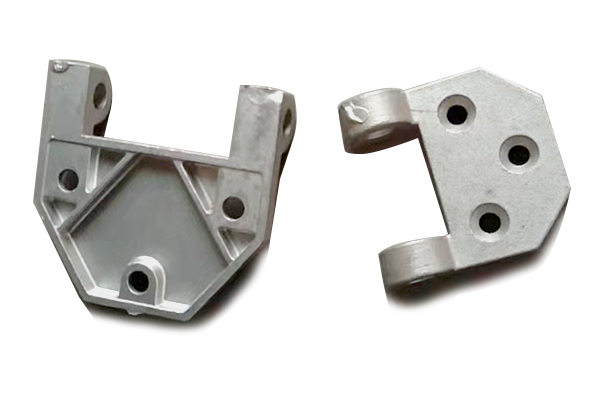

How are the hinge blocks for heavy-duty butt hinges produced?

The hinge blocks for heavy-duty butt hinges are also produced by the two processes described above. If the stamping process is used, then at least two processes are required to produce a hinge block.

The first process is the lowering process, which allows the hinge block to be stamped into shape as a whole. The second process is the bending or punching of the hinge block, the complex part of which is the cylindrical hole where the hinge shaft is mounted. This stamping and forming process requires several steps.

If it is produced by the die-casting process, then the structure can be die-cast in one go. Because this process is equivalent to having a chamber in the shape of a hinge block beforehand, we simply pour a molten metal liquid into the chamber and fill it to the brim with water. After the metal liquid cools and cures, it is then taken out, and the production of a hinge block is completed.

How are the hinge shafts for heavy-duty butt hinges manufactured?

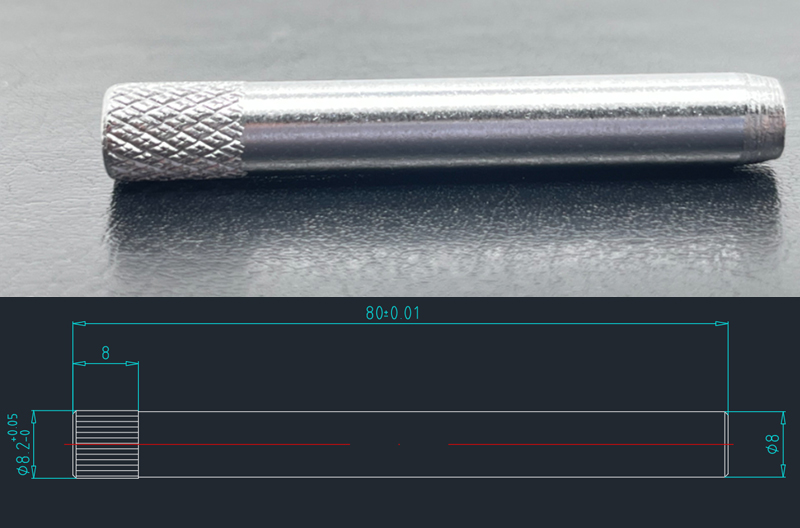

As we said, the hinge shaft is the single most important component of the hinge. Because it is the key connecting piece, without this shaft or with a poor-quality shaft, this would be disastrous. That’s why all heavy-duty butt hinges manufactured by IHINGES are made of stainless steel.

So how is the hinge shaft produced? In fact, we only need to go to the market to purchase the stainless steel round bar material back. Fine processing can be done. This processing process is the most important. If it does not meet the design requirements of the drawings, the result is either the hinge block can not turn between, or the hinge in the process of use, the shaft is easy to fall off, can not connect the two hinge blocks firmly.

Therefore, the processing of the hinge shaft must be strictly in accordance with the design requirements of the drawing, with emphasis on the marked tolerance requirements.

How do I install the hinge shaft?

There are different ways to install the hinge shaft with the hinge block, there are three main ways.

- One is to make one end of the hinge shaft thicker. And to fix one of the hinge blocks to the hinge shaft by overfitting the shaft holes on the hinge shaft also hinge blocks. This mounting method is generally suitable for hinges with relatively small load-bearing capacity. It is also the most widely used method of mounting hinge shafts.

However, one problem with this method of mounting hinges is that when the hinge shaft is withdrawn and mounted twice. It cannot be passed through the hole of the original hinge block. But must be passed through the hole of another hinge block. Because the original hole has been enlarged, installing it again will cause the hinge shaft to loosen or even fall off.

- Another way is to drill and tap the holes in the hinge shaft and hinge block. Use the installation screws to fix one of the hinge blocks to the hinge shaft as a whole.

- The third way is to make the length of the hinge shaft larger than the length of the hinge block. So that the exposed part of the hinge shaft can be perforated and a pin can be installed for locking. This way is mainly used for heavy hinges.

How to assemble heavy-duty butt hinges?

To assemble heavy-duty butt hinges, you need to use jigs. One of the most important tools is the manual punch. It is used to install the hinge shaft and press it down. And secure it to the hinge block as a whole. If the hinge shaft is in other forms, then this tool is not needed. And it is only necessary to fix it with screws or install pins.

It should be noted that after installation, workers need to check whether the hinge blocks can turn smoothly between them. If the rotation is not possible or the rotation is very hard. Then it means that the hinge block or the hinge shaft has a deformation phenomenon. This situation will be judged as unqualified products.