Description

Refrigeration door hinges are hinges designed specifically for use in refrigeration equipment, such as refrigerators, freezers, and other cold storage units. These hinges are designed to withstand the low temperatures and high humidity levels that are typical of refrigeration environments, while also ensuring that the doors of these units remain securely attached and function properly.

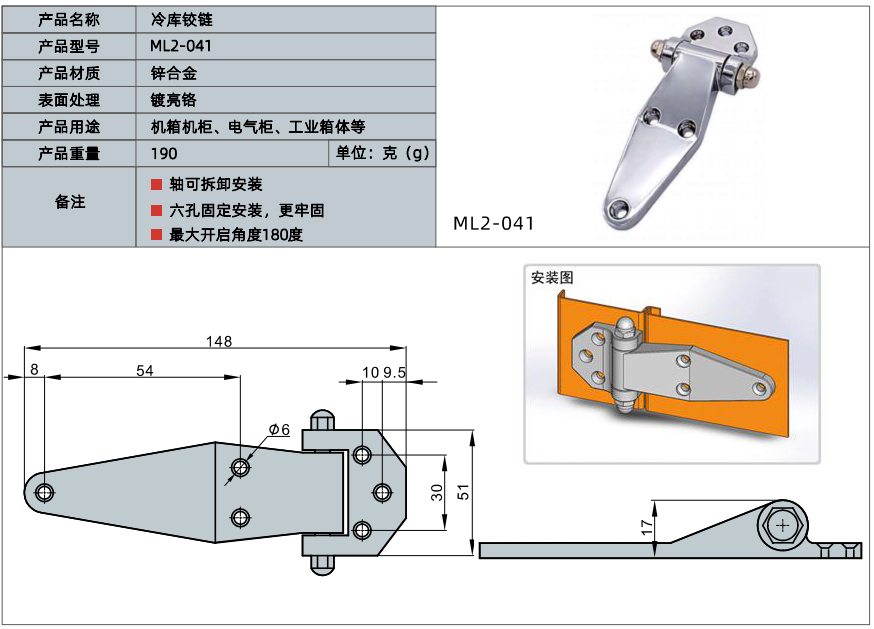

Refrigeration door hinges are typically made from high-quality materials that are corrosion-resistant and can withstand extreme temperatures. They are available in a variety of sizes and styles to fit different types of doors and frames. Some common materials used for refrigeration door hinges include stainless steel, brass, and aluminum.

Features:

Corrosion-resistant materials: Refrigeration door hinges are made from materials that are resistant to corrosion and rust, ensuring long-lasting performance in harsh environments.

Temperature-resistant design: These hinges are designed to withstand extreme temperatures and high humidity levels, making them suitable for use in refrigeration equipment.

Easy installation: Refrigeration door hinges are typically easy to install and can be secured to the door and frame using screws or bolts.

Variety of sizes and styles: They are available in a range of sizes and styles to fit different types of doors and frames, providing flexibility in design and installation.

Durable construction: Refrigeration door hinges are built to withstand frequent use and heavy loads, ensuring reliable operation over time.

Sealed construction: Some refrigeration door hinges are designed with a sealed construction, which helps to prevent moisture from entering the hinge and causing damage over time.

FAQs:

What are the different types of refrigeration door hinges?

There are several types of refrigeration door hinges, including spring-loaded hinges, concealed hinges, and self-closing hinges. Spring-loaded hinges are designed to provide a strong, reliable closing force, while concealed hinges are hidden from view and provide a clean, streamlined appearance. Self-closing hinges are designed to automatically close the door when it is released.

What materials are used to make refrigeration door hinges?

Refrigeration door hinges are typically made from materials that are resistant to corrosion and rust, such as stainless steel, brass, and aluminum. Some hinges may also be coated with a protective layer or finish to enhance their durability and resistance to environmental factors.

How do I know if I need to replace my refrigeration door hinges?

Signs that it may be time to replace your refrigeration door hinges include difficulty opening or closing the door, excessive noise or squeaking, or visible signs of wear or damage on the hinges themselves. Regular inspections and maintenance can help to identify issues with the hinges before they become more serious.

Can I install refrigeration door hinges myself, or do I need a professional?

While it is possible to install refrigeration door hinges yourself, it is recommended that you seek the assistance of a professional if you are unsure of how to do so properly. Improper installation can lead to issues with the hinge’s function or durability, as well as potential safety hazards.

How can I maintain my refrigeration door hinges to ensure optimal performance?

Regular maintenance and cleaning can help to ensure that your refrigeration door hinges continue to function properly over time. This may include wiping down the hinges with a clean cloth, lubricating the moving parts, and tightening any loose screws or bolts as needed. In addition, it is important to monitor the hinges for signs of wear or damage and to replace them as needed to prevent potential safety hazards.