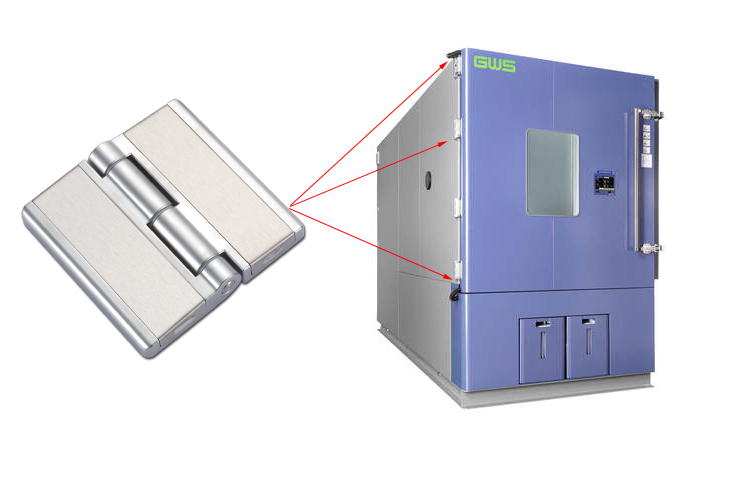

Temperature test chamber hinges play a crucial role in industrial applications, ensuring durability and precision in extreme temperature conditions. In this article, we will explore the significance of hinges and how they contribute to reliable and accurate temperature control.

Understanding Temperature Test Chambers

Temperature test chambers are essential in industrial testing, providing controlled environments to simulate various temperature conditions. Hinges play a pivotal role in these chambers, enabling smooth operation and secure sealing to maintain desired temperature levels.

Challenges in Extreme Temperature Environments

A. Impact of Temperature on Hinges

Extreme temperatures can significantly affect hinge performance, causing material expansion or contraction. It is vital to select hinges capable of withstanding these temperature fluctuations to ensure optimal functionality and longevity.

B. Maintaining Stability and Precision

Precise temperature control is crucial in testing environments to obtain accurate results. Hinges contribute to maintaining stability within the chamber, preventing temperature fluctuations that could compromise the integrity of the testing process.

Key Features of Temperature Test Chamber Hinges

A. Materials for High-Temperature Environments

Hinges for temperature test chambers require materials that can withstand the rigors of extreme temperatures. Stainless steel and heat-resistant alloys offer excellent properties such as high thermal conductivity, corrosion resistance, and structural integrity.

B. Specialized Design Considerations

Optimizing hinge design is essential for temperature test chambers. Factors such as thermal expansion, sealing mechanisms, and proper lubrication are carefully considered to ensure smooth operation, enhanced durability, and precise temperature control.

Ensuring Durability and Longevity

A. Load-Bearing Capacity in Temperature Test Chamber Hinges

Temperature test chambers often handle heavy loads, and hinges must be capable of bearing these loads without compromising performance or safety. Selecting hinges with adequate load-bearing capacity is crucial to ensure equipment durability and reliability.

B. Resistance to Thermal Stress

Hinges in temperature test chambers must withstand thermal expansion and contraction, which can exert significant stress. Temperature-resistant hinges, designed to handle these stressors, offer increased durability, minimizing the risk of hinge failure.

Maintenance and Care for Temperature Test Chamber Hinges

A. Lubrication and Corrosion Prevention

Proper lubrication of hinges in high-temperature environments is essential to reduce friction, ensure smooth operation, and prevent premature wear. Additionally, implementing corrosion prevention measures enhances the longevity and performance of the hinges.

B. Regular Inspection and Adjustment

Routine inspections are necessary to identify any potential issues with the hinges. Adjusting hinges as needed and addressing any signs of wear or misalignment can help maintain optimal performance and prevent unexpected failures.

Case Studies: Success Stories

Examining real-world examples of temperature test chamber hinge applications showcases their impact in various industries and testing scenarios. We will explore how hinges have played a crucial role in optimizing efficiency, durability, and precision.

Future Developments and Trends

Advancements in temperature test chamber hinge technology are continuously being explored. This section delves into emerging trends, innovations, and predictions for the future, highlighting how these developments will further enhance durability and precision in temperature-controlled environments.

Conclusion

In my experience, temperature test chamber hinges are vital components in industrial applications, combining durability with precision to ensure reliable and accurate temperature control. By understanding the challenges, key features, and maintenance practices associated with these hinges, businesses can optimize their testing processes and achieve superior results. Selecting and caring for the right hinges is paramount for achieving efficiency, durability, and precision in temperature test chambers. If you are looking for this type of hinge, please contact us now.