Industrial equipment often requires specialized components to ensure durability and functionality under harsh conditions. One such critical component is the door hinge. Selecting the right type of hinge is not only essential for the operational efficiency of equipment but also for safety and longevity. This article aims to provide an in-depth understanding of the 12 most common types of door hinges used in industrial equipment, exploring their unique features and applications.

When it comes to industrial equipment, every detail matters, and door hinges are no exception. From heavy machinery to delicate instruments, the type of hinge can significantly impact the performance and reliability of a device. This guide will delve into various hinge types including butt, piano, marine, and more, each tailored for specific industrial needs.

Selecting the right hinge can be a complex task, given the range of options available. This article breaks down the differences, advantages, and ideal use-cases of each hinge type, helping you make an informed decision for your industrial applications.

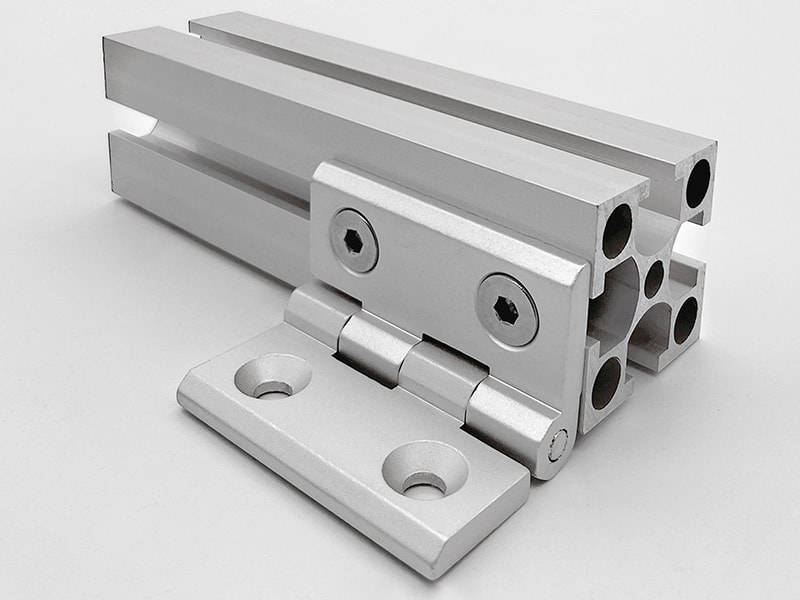

Butt Hinges

Butt hinges are among the most commonly used hinges in both residential and industrial settings. They consist of two rectangular metal plates with screw holes, joined by a pin or a rod.

These hinges are favored for their simplicity and versatility, easily accommodating doors of various sizes and weights. In industrial settings, they are particularly valued for their strength and durability, often made of robust materials like steel or brass.

Butt hinges are relatively easy to install and adjust, making them a practical choice for a wide range of industrial equipment. They are ideal for applications where the alignment and smooth operation of doors are crucial.

Piano Hinges

Piano hinges, also known as continuous hinges, run the entire length of the door or lid they are attached to.

This design distributes weight and stress along the entire length of the hinge, making it an excellent choice for industrial applications requiring long, heavy doors or lids.

Made typically from steel, aluminum, or brass, piano hinges are highly durable and can be cut to the desired length. They are particularly useful in applications where a stable and secure connection is needed over a large area, such as large industrial storage cabinets or access panels.

Marine Hinges

Marine hinges are designed specifically for environments where corrosion and rust are major concerns, such as in ships or coastal industrial plants.

These hinges are usually made from materials like stainless steel or brass, which resist corrosion and can withstand exposure to harsh elements.

Their design varies from butt to strap styles, catering to different needs in marine applications. These hinges are essential for equipment exposed to moisture, salt, and other corrosive elements, ensuring longevity and reliability.

Special Hinges

Special hinges are custom-designed for specific applications or unique industrial equipment.

These hinges are tailored to meet exact specifications, often required in specialized machinery or equipment with unusual door or lid movements.

Manufacturers work closely with industrial clients to design hinges that meet the precise requirements, whether it’s unusual load-bearing capacities, specific movement patterns, or unique environmental conditions.

Aluminum Hinges

Aluminum hinges are known for their lightweight yet strong properties, making them ideal for applications where weight is a critical factor.

These hinges are commonly used in aerospace and automotive industries, where reducing weight without compromising strength is essential.

Apart from being lightweight, aluminum hinges are also resistant to corrosion, making them suitable for outdoor or harsh industrial environments. Their versatility makes them a popular choice in various industrial applications.

Concealed Hinges

Concealed hinges are designed to be invisible when the door is closed, providing a clean, seamless look.

In industrial settings, these hinges are often used in equipment where aesthetics are important, or where external hinges could interfere with operations.

These hinges are not just about appearances; they also offer added security by being less accessible for tampering. Concealed hinges come in various designs and strengths, suitable for different industrial applications.

Detachable Hinges

Detachable hinges, as the name suggests, allow doors or panels to be easily removed without the need for tools.

This feature is particularly useful in industrial equipment that requires frequent maintenance or access to internal components.

These hinges provide the convenience of quick access while maintaining the security and durability needed in industrial settings. They are commonly used in machinery where regular cleaning or part replacement is necessary.

Trailer Door Hinges

Trailer door hinges are designed to withstand the rigors of road travel, often being heavy-duty and able to support large, heavy doors.

They are typically made from robust materials like steel or stainless steel and are designed to withstand vibration, shock, and varying weather conditions.

These hinges are essential in ensuring the safety and security of cargo during transportation. Their durability and strength are crucial for trailers used in construction, logistics, and other industries.

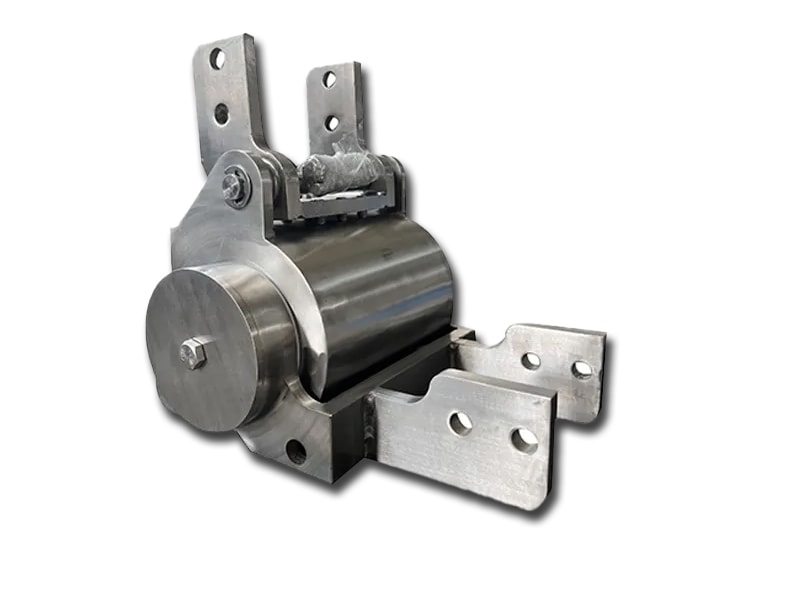

Heavy Duty Hinges

Heavy duty hinges are built to support high loads and frequent usage, common in industrial environments.

These hinges are often larger and thicker than standard hinges, made from materials like hardened steel or iron.

They are designed to withstand extreme forces, making them ideal for heavy industrial doors, gates, and machinery. These hinges ensure reliable operation under tough conditions, such as in manufacturing plants or heavy machinery.

Weld on Hinges

Weld on hinges are directly welded onto the door and frame, providing a strong, permanent connection.

These hinges are ideal for applications where screws or bolts are not feasible or desirable, such as in high-security areas or heavy-duty equipment.

Made typically from steel or stainless steel, weld on hinges offer a robust solution for heavy doors and gates, often used in industrial facilities and construction equipment.

Cold Storage Room Hinges

Cold storage room hinges are designed specifically for use in refrigerated environments, such as walk-in freezers or cold storage warehouses.

These hinges are built to withstand low temperatures and potential condensation, often featuring special coatings or materials to prevent rust and corrosion.

Their design ensures a tight seal to maintain consistent temperatures, essential for preserving the quality of stored goods. These hinges are critical in industries like food processing and pharmaceuticals.

Climatic Test Chamber Hinges

Climatic test chamber hinges are tailored for equipment used in testing and simulating different environmental conditions.

These hinges must withstand extreme temperatures, humidity, and other environmental stressors, ensuring the integrity of the test chambers.

Made from materials that can endure these conditions, these hinges are crucial in industries where product testing under controlled environmental conditions is necessary, like aerospace, automotive, and electronics.

Conclusion

Choosing the right hinge for industrial equipment is crucial for ensuring functionality, safety, and longevity. This guide provides an overview of the most common types of door hinges used in industrial settings, each with its unique features and applications. Understanding these options will help in making informed decisions for your specific industrial needs.

You might be interested: