When it comes to the world of industrial hinges, it’s not uncommon to hear about various grades, including “Grade 7”. The question that usually follows is, “What exactly are Grade 7 hinges?” It’s a valid query, especially when your industrial operations hinge on the efficiency, strength, and durability of this crucial hardware component.

Grade 7 hinges, according to BS EN 1935, are high-performance hinges designed to handle doors weighing up to 120 kg. These hinges are subject to stringent testing to ensure their durability, strength, and reliability in heavy-duty applications in the industrial sector.

Let’s delve into the world of Grade 7 hinges, understand what sets them apart, and why they might be the right fit for your industrial needs.

What makes Grade 7 hinges unique?

What differentiates Grade 7 hinges from the others? It’s the weight capacity and durability. The weight a hinge can carry is determined by its grade, and a Grade 7 hinge is designed to support doors weighing up to 120 kg.

Not only can these hinges handle heavy weight, but they’re also built to withstand frequent use. Their durability is tested through rigorous cycles of opening and closing. This means that Grade 7 hinges are not only strong but also incredibly long-lasting, making them ideal for heavy-duty industrial applications.

What are the testing criteria for These hinges?

When it comes to Grade 7 hinges, rigorous testing standards are in place. But what are these testing criteria? The BS EN 1935 standard outlines the various tests these hinges must pass to earn their grade.

The tests include durability, strength, and security. For durability, the hinges are tested for 200,000 cycles of opening and closing. Strength testing involves applying excessive force to the hinge to ensure it can withstand stress. Finally, the security tests check if the hinge can resist attempts at forced entry.

What types of materials are used for The hinges?

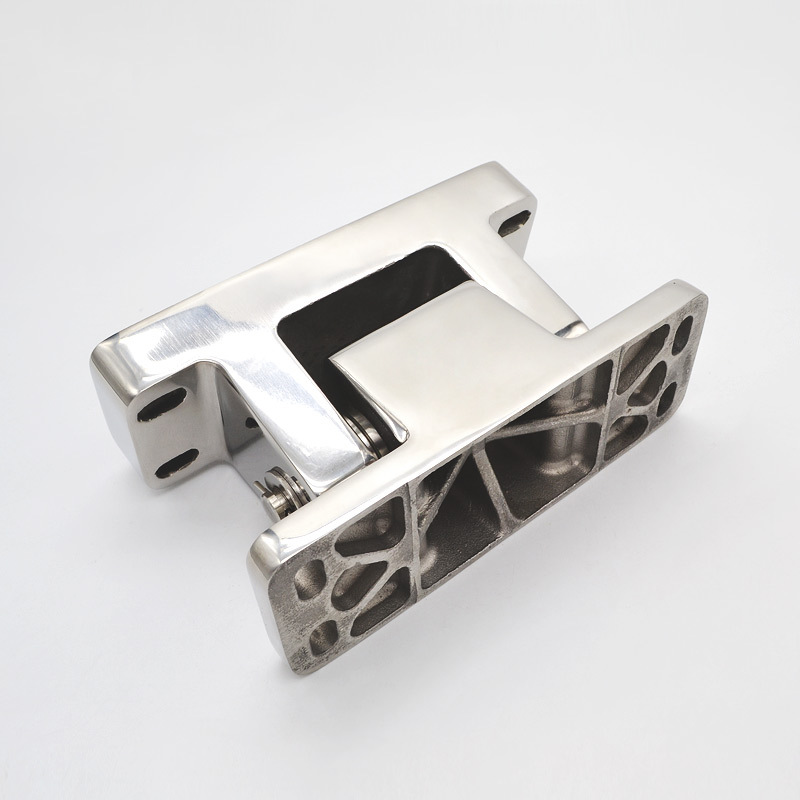

The hinges are often made from hard-wearing materials, such as stainless steel and brass. These materials are chosen for their inherent strength, durability, and resistance to corrosion.

Stainless steel, with its robust nature and resistance to rust, makes it an ideal material for hinges that need to withstand heavy loads and frequent use. On the other hand, brass hinges, although not as strong as stainless steel ones, offer great resistance to corrosion, making them suitable for environments where rust and corrosion can be a concern.

Can Grade 7 hinges be used for fire doors?

In industrial settings, it’s not uncommon to use fire doors to prevent the spread of fire. So, can Grade 7 hinges be used for fire doors?

The answer is a resounding yes. These hinges are often fire-rated, meaning they’ve been tested to withstand intense heat for a specified period. These hinges are a perfect fit for fire doors, playing a vital role in preventing the spread of fire and maintaining safety in industrial settings.

How to install the hinges?

Installation of the hinges, while not fundamentally different from other types, does require a bit more care due to the weight they carry. These hinges should always be installed with the correct screws and fixings specified by the manufacturer.

It’s recommended that all fixings provided with the hinge are used and that the door is correctly aligned. Improper installation could potentially affect the hinge’s ability to carry the door weight and compromise its performance.

What about the maintenance of Grade 7 hinges?

Like all hardware, these hinges also require routine maintenance. Due to their frequent usage and the weight they handle, it’s crucial to check and maintain these hinges regularly.

Typical maintenance includes cleaning the hinges to remove any grime or dirt, checking for any signs of wear, and ensuring the hinge’s screws are tight. In some cases, these hinges might also require lubrication to ensure smooth operation.

How to choose the right Grade 7 hinges?

Choosing the right Grade 7 hinges depends on a few factors, including the weight of the door, material, and fire rating requirements. It’s important to know the weight of your door and choose a hinge that can comfortably support it.

The hinge material should be suited to your environment, particularly if it’s exposed to elements that could cause corrosion. If you’re dealing with fire doors, ensure your hinges are fire-rated. Lastly, always opt for hinges from a trusted brand to ensure quality and reliability.

Conclusion

In conclusion, Grade 7 hinges are designed for heavy-duty applications, supporting door weights up to 120 kg. Made from robust materials like stainless steel and brass, these hinges pass stringent tests for durability, strength, and security. Whether it’s for fire doors or regular industrial doors, with the right installation and maintenance, The hinges offer an effective solution for your industrial needs.

You might also be interested: