In the realm of industrial testing and experimentation, walk-in test chambers play a crucial role in ensuring the reliability and safety of various products. These chambers simulate real-life conditions to assess the performance of components, materials, and finished products under extreme temperatures, humidity levels, and other environmental factors. An integral part of these test chambers is the hinges, which enable the smooth and reliable operation of the chamber doors. In this article, we will delve into the world of walk-in test chamber hinges, exploring their features, functionality, selection criteria, and customization options.

What are Walk-In Test Chamber Hinges?

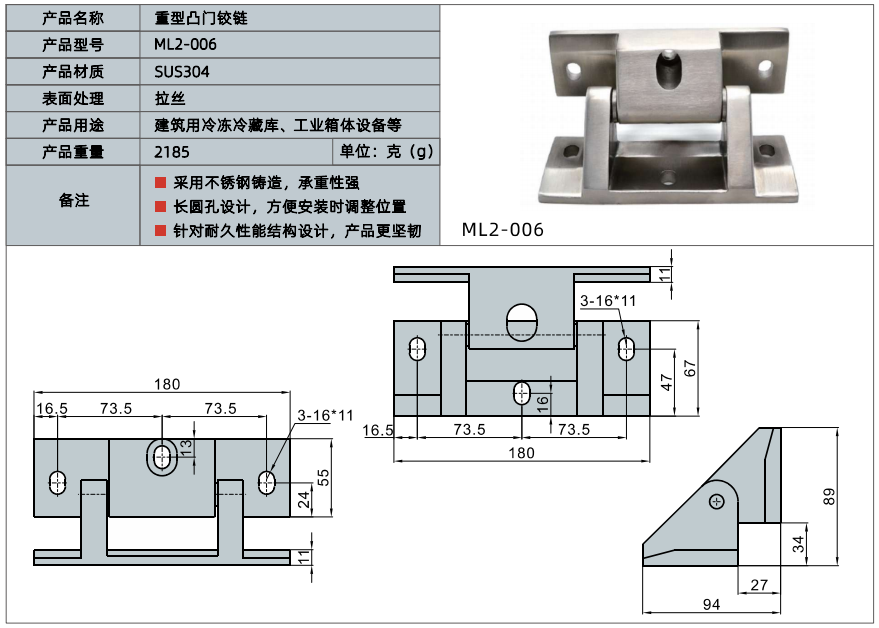

Walk-in test chamber hinges are specially designed components that facilitate the smooth opening and closing of the chamber doors. They provide stability and ensure a secure seal, preventing the ingress or egress of air, moisture, or other external elements during testing procedures. These hinges are engineered to withstand the demanding conditions within the test chambers, including extreme temperatures, humidity fluctuations, and exposure to corrosive substances. By providing robust support to the heavy doors, they enable easy access to the testing environment while maintaining the integrity of the controlled conditions.

These hinges are different from boat hinges, mainly because of the different structures and the different range of use. When choosing hinges, we need to determine the actual scope of use and installation structure.

What are the features of Walk-In Test Chamber Hinges?

Walk-in test chamber hinges boast several features that make them suitable for industrial testing environments. Firstly, they are typically constructed from high-quality materials such as stainless steel or other corrosion-resistant alloys to withstand harsh conditions and ensure durability. These materials possess excellent strength and resistance to temperature variations, ensuring the hinges can function reliably over extended periods.

Additionally, walk-in test chamber hinges often incorporate advanced sealing mechanisms to enhance the airtightness of the chamber doors. This feature is crucial for maintaining precise control over the internal environment, as even minimal air leakage can compromise the accuracy and validity of test results. Some hinges may also feature specialized gaskets or seals to provide additional protection against moisture or dust infiltration, further safeguarding the testing environment.

Another notable feature of walk-in test chamber hinges is their design versatility. Manufacturers offer a range of hinge configurations to accommodate different door sizes, weights, and orientations. This allows for flexibility in chamber design and ensures compatibility with various testing requirements. Some hinges may also provide adjustable tension mechanisms, enabling precise control over the door movement and reducing the risk of damage caused by excessive force or swinging.

How do Walk-In Test Chamber Hinges work?

Walk-in test chamber hinges employ a combination of mechanical design principles to facilitate smooth door operation. Typically, they utilize a pivot mechanism that enables rotational movement of the door around a fixed axis, allowing easy opening and closing. The pivot point is strategically positioned to maintain optimal weight distribution and balance, ensuring effortless movement of the heavy chamber doors.

Furthermore, many hinges incorporate built-in lubrication systems to minimize friction and wear, thereby prolonging their lifespan and reducing maintenance requirements. These systems may consist of self-lubricating components or provisions for manual lubrication, ensuring consistent performance over prolonged usage.

How to choose the right Walk-In Test Chamber Hinges?

Selecting the appropriate walk-in test chamber hinges requires careful consideration of various factors. Firstly, it is crucial to assess the specific requirements of the testing application, including the size and weight of the chamber doors, the frequency of door operation, and the environmental conditions the hinges will be subjected to. This evaluation will help determine the hinge material, load-bearing capacity, and corrosion resistance needed for optimal performance.

Additionally, considering the ease of installation and maintenance is essential. Hinges that offer simple installation mechanisms, such as bolt-on or adjustable mounting options, can significantly streamline the setup process. Similarly, hinges with easy access to lubrication points or self-lubricating capabilities can reduce maintenance efforts and minimize downtime.

Collaborating with reputable suppliers or manufacturers with expertise in chamber hinges is crucial for obtaining high-quality products. They can provide valuable guidance and support. Assisting in the selection of hinges that align with specific testing requirements and industry standards.

Is it possible to customize Walk-In Test Chamber Hinges?

Indeed, many manufacturers offer customization options for the chamber hinges to cater to unique project needs. Customization may involve tailoring the hinge dimensions, load-bearing capacity, or material composition to suit specific chamber door configurations. Manufacturers can also integrate additional features like advanced sealing mechanisms, and vibration dampening. Or noise reduction capabilities based on the desired application.

Furthermore, the aesthetic aspects of the hinges can also be customized to align with the overall design and branding of the testing facility. Options for custom finishes, colors, or labeling are often available to create a cohesive and professional appearance.

Conclusion

Walk-in test chamber hinges are critical components that ensure the smooth and reliable operation of chamber doors in industrial testing environments. With their durable construction, advanced sealing features, and design versatility. These hinges play a vital role in maintaining the integrity of controlled testing conditions. By carefully considering the specific requirements of the application. Selecting high-quality hinges, and exploring customization possibilities. Businesses can optimize their testing processes and achieve accurate and reliable results. Collaborating with reputable suppliers or manufacturers will provide the necessary expertise to guide the selection and customization process. Ensuring optimal performance and long-term durability of test chamber hinges.

Web Design Directory – A list of website designers in Cheshire.