In the world of aviation, the engineering behind the scenes is an intricate ballet of parts and systems, each playing its role in ensuring the safety and efficiency of a flight. One such system, often overlooked, is the humble hinge. Yes, that’s right – hinges. These seemingly simple components are a crucial part of aircraft, but what type of hinges are used in an aircraft?

When it comes to aircraft, hinges are everywhere – from the control surfaces such as the ailerons, rudder, and elevators, to the cargo and passenger doors, and even in the engine compartments. Each hinge is a marvel of engineering, specifically designed and located to carry out a precise function.

So, join me as we embark on a journey into the world of aircraft hinges, exploring their types, purposes, and intricate design processes behind them.

How are Center Hinged Aircraft Hinges Utilized?

The center hinged design is a common choice for the elevators and rudder on an aircraft. They pivot around a central point, thereby allowing the control surfaces to move as required. These hinges need to be robust and resilient to withstand the constant force exerted on them during flights.

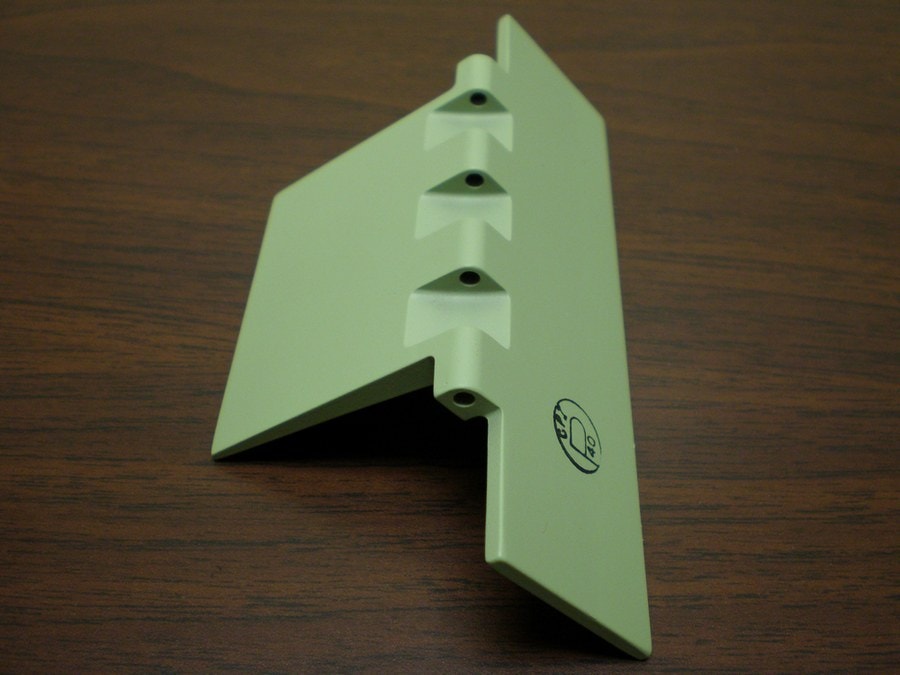

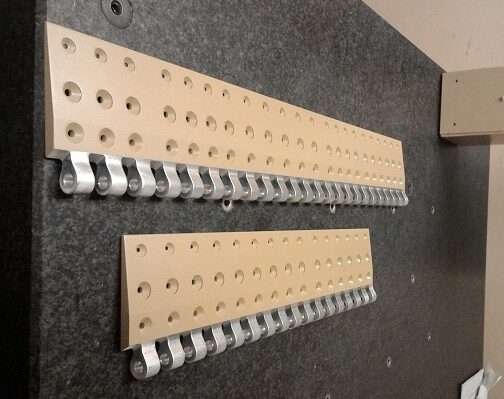

A unique feature of center hinged designs is the incorporation of ‘hinge block’ design. Aimed at simplifying the manufacturing process, while ensuring a strong, functional hinge, the hinge block allows easy replacement of the ‘bearing’ material if wear occurs, making it a practical design for aircraft maintenance.

What are the Roles of Top Hinged Aircraft Hinges?

The top hinged design is typically found on ailerons. They’re strategically located at the top, allowing the aileron to pivot both upwards and downwards. This functionality of top hinged hinges plays a pivotal role in controlling the roll of the aircraft.

These hinges are built to endure significant loads and stress. Much like center hinged designs, top hinged aircraft hinges often incorporate a ‘hinge block’ design. This design feature allows for the simplicity of manufacture, strength, and ease of maintenance that aircraft hinges require.

Can you Describe Bottom Hinged Aircraft Hinges?

Bottom hinged designs, another key component in an aircraft’s arsenal, are employed on ailerons, flaps, and accessory doors. The bottom hinge allows a control surface to pivot downward, making them suitable for ailerons and flaps.

The pressure of takeoff and landing places high stress on these hinges, necessitating a robust design. Much like their counterparts, bottom hinged designs also use a ‘hinge block’ design, simplifying manufacture and upkeep.

What Materials are Preferred in Crafting Aircraft Hinges?

The materials used in aircraft hinges must offer strength and durability. Common choices include aircraft-grade plywood, NY-ROD for the bearing, and music wire for the hinge pin.

These materials ensure a long functional life for the hinge, even under severe operating conditions. Another advantage of this design is that the bearing, prone to wear over time, can be easily replaced even after the aircraft has been painted.

How Important is the Maintenance of Aircraft Hinges?

The maintenance of aircraft hinges is of paramount importance. These components are designed for longevity and minimal maintenance, yet like any part of an aircraft, they require regular inspections.

Routine checks are done for signs of wear and tear, and replacements are made if necessary. Thanks to their design, the replacement process is fairly straightforward, especially for the bearing material.

Could You Explain the Installation Process of Aircraft Hinges?

The installation process for aircraft hinges demands precision and technical know-how. The process begins with cutting the hinges into shape, drilling them for a press fit of the bearing, followed by its installation and trimming to fit flush with the hinge sides.

This approach allows a snug fit, minimal wobble, and enables precise movement of the aircraft’s control surfaces, enhancing overall performance and safety.

What is the Impact of Aircraft Hinges on Flight Safety?

Aircraft hinges play a vital role in ensuring flight safety. The efficiency of these hinges and their strategic placement enables accurate control of the aircraft’s movements. Any malfunctioning hinge could lead to loss of control, underlining the importance of their maintenance.

Moreover, the use of robust materials and efficient designs further minimizes the risk of hinge failure, hence playing a crucial role in enhancing flight safety.

Conclusion

As we conclude our journey through the world of aircraft hinges, it’s clear that these unsung heroes play a pivotal role in aviation. From center hinged to top and bottom hinged designs, each type of hinge has a unique function and importance in an aircraft. Their robust materials, thoughtful design, ease of installation, and critical role in maintaining flight safety make these hinges a fundamental part of aviation engineering. So, the next time you fly, remember that the safe and smooth flight is in part thanks to the intricate world of aircraft hinges.

You might also be interested: