Industrial testing equipment is a relatively special class of equipment. It is used to test the indicators and performance of the products we produce. Today I would like to introduce you to this equipment is one of them, the constant temperature humidity test chamber. But the focus is on the industrial hinges installed on the constant temperature humidity test chamber equipment.

I will introduce the following 8 aspects of the constant temperature humidity test chamber industrial hinges. If you are a manufacturer of the equipment, it may be helpful to you.

What is a constant temperature humidity test chamber?

It mainly refers to the use of refrigeration equipment, heating equipment, humidification equipment, and dehumidification equipment will test chamber temperature and humidity control in a certain period of time in a constant range, used to artificially create a specific temperature and temperature environment, the specific equipment for environmental testing, in order to identify problems, improve the design and production process purposes.

constant temperature humidity test chambers according to the size and placement are divided into desktop constant temperature humidity test chambers, vertical constant temperature humidity test chambers, humidity constant temperature humidity test chambers, and walk-in constant temperature humidity test chambers in three categories. Table-top constant temperature humidity test chamber studio volume is relatively small, suitable for small or micro parts, equipment reliability testing generally put it on the bench can; vertical constant temperature humidity test chamber studio volume between 80L-1000L is generally used to test the volume of slightly larger parts or equipment.

What is a test chamber industrial hinge?

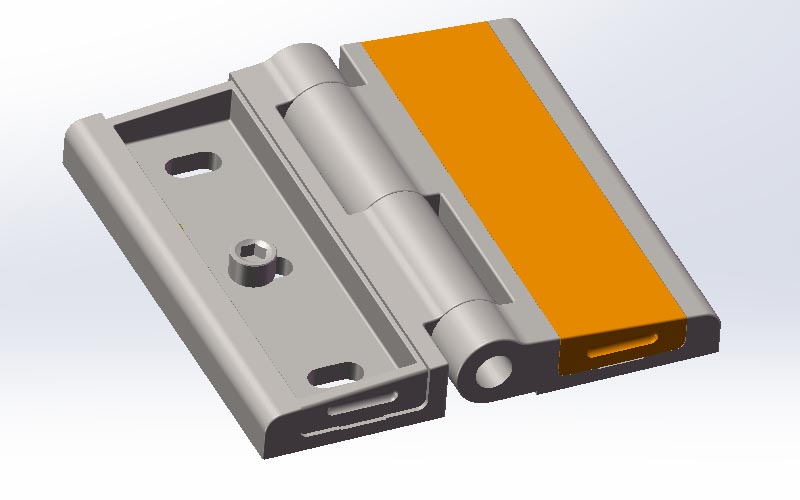

A thermostat industrial hinge is a heavy-duty industrial hinge specifically used on this type of equipment. It is mainly used for door connections. And bearing the weight of the door. It is only a small part of the equipment A small part. But the role is very important. It can directly affect the reliability of the test equipment.

Constant temperature humidity test chamber industrial hinges are generally installed in a flat type. Different forms of constant temperature humidity test chambers using industrial hinges are generally similar, only slightly different in appearance structure.

Their most important role is to connect the door and door frame, in addition, to bear the weight of the door. In some cases, the door and the door frame are not flush, so it is necessary to use a step type of industrial hinges.

Next, I will continue to introduce knowledge about the different aspects of the constant temperature and humidity box industrial hinges.

The difference between constant temperature humidity test chamber industrial hinges and other hinges

The constant temperature humidity test chamber industrial hinge is a hinge product. It is similar to the butt hinges we usually see, mainly until the role of connecting the door and door frame and carrying the weight of the door. So from this aspect, they are the same kind of products.

However, since the hinge is an accessory product, it cannot perform a function alone. It has to be installed on a device in order to perform its function. Therefore, different equipment requires the need to the installation of different hinges. The industrial hinge of constant temperature and humidity box is a kind of professional hinge, which is different from the ordinary hinge.

This type of hinge has the characteristics of a large-size structure and strong load-bearing performance. Because it is installed on the equipment must meet the strong weight-bearing requirements, in addition to matching the large box The appearance of the equipment.

The core of industrial hinges for constant temperature humidity test chambers is thicker than that of ordinary hinges. The core is an important part that determines the load-bearing performance of the hinge and is generally processed in stainless steel Shaft core.

What are the characteristics of the constant temperature humidity test chamber industrial hinge?

The characteristics of the constant temperature humidity test chamber industrial hinges are mainly the following 4 points.

- Mainly using zinc alloy material or stainless steel material production. In order to achieve the requirements of load-bearing, hinges are made of zinc alloy or stainless steel. And stainless steel material quality is The best quality of a class of materials. Its strength is much higher than that of zinc alloy.

- The size structure is relatively large. With the constant temperature humidity test chamber is generally relatively large equipment, and its matching product accessories also need to be correspondingly larger in size. If the adoption of The use of too small sizes will make people feel unsuitable, or feel no sense of security.

- The hinge core is made of stainless steel. This type of hinge core is generally produced using stainless steel, mainly 304 stainless steel material. This type of material is the most widely used class of stainless steel material. It has good corrosion resistance and strength and can be used for a long time without hair deformation or rusting.

- Exclusive use. This type of hinge is widely used in a more specific application, mainly for this type of large box equipment on the door. Although there are subtle differences between different equipment, the hinges are generally used in the same way. In general, these hinges are used on such equipment and are not generally used on ordinary doors.

How to choose a constant temperature humidity test chamber industrial hinge

If you are now looking for a constant temperature humidity test chamber industrial hinges, the following 4 points of attention can refer to.

- Hinge structure. If your equipment door is flush with the door frame, then use a flat type of hinge installed. If it has a step type, then use a step-type hinge. This is believed to be relatively easy to determine.

- Size. The size of the size should be evaluated according to the size of their own equipment. This process also does not need to be too strict, intuition can know the equipment needs to be configured roughly how big Size of the hinge is. Obviously too small or too large are not appropriate. Focus on the overall aesthetics of the equipment is also very important to work.

- Load-bearing performance. This is an important parameter, be sure to know the important weight of their equipment door. Also, determine how many hinges we are prepared to install on the door. This will then determine the size of the individual hinges required to support the weight.

- Material. The material must be considered. If our door is particularly heavy, it is recommended to use stainless steel for safety reasons. Although sometimes zinc alloy gold material can also meet the requirements. But according to their own actual situation to decide which material is the safest.

How to install the test chamber industrial hinges

Regarding how to install the constant temperature humidity test chamber industrial hinges, I think the workers have the most experience. I will briefly explain the installation steps and focus on the details to pay attention to here.

First, you need to determine the installation position of the hinge. Generally, the ends of the equipment door to install hinges, and the location of the installation should be relatively close to the edge, not too far away. This way on the one hand, On the one hand, it is not coordinated, and on the other hand, it is not safe, especially for the higher doors.

Second, when installing the hinges, you can first install the hinges on the door frame, and finally, lift the door to install them. This can reduce the difficulty of installation. The process of installation It is best to place a level to ensure that the door is level.

Finally, after the installation is completed, check to see if there is any effort in the process of closing or opening the door or the occurrence of the strange noise. This inspection work is very important.

What are the important parameters of the test chamber industrial hinges?

The important parameters of the industrial hinge of the constant temperature and humidity box are mainly as follows.

- Size. Appearance size can determine whether the installation space is suitable. In addition, the size of the installation hole can guide workers to open the location of the hole and the specifications of the installation screws.

- Shaft core. The core is an important part, and we have mentioned its importance above. So the thickness of the core needs to be understood, especially when our equipment door The case of very heavy weight.

- Surface treatment. Zinc alloy material generally adopts electroplating, electrophoresis, spraying, and other surface treatment, and stainless steel material generally adopts polishing, grinding, and other surface treatment. According to The actual situation to decide which one to use.

- Load-bearing performance. To know the size of a single hinge load-bearing, so as to decide whether it is suitable for the weight of the door, or how many hinges to install.

- Opening angle. The opening angle of the hinge directly determines the opening angle of the door. This parameter is necessary to understand.

How to order a test chamber industrial hinge

If you need to order a constant temperature humidity test chamber industrial hinge, then you have come to the right place. IHINGES is a professional manufacturer of custom-made industrial hinges. Especially for industrial, We have been working on this niche for a long time, especially for industrial testing equipment. We have developed a variety of specialized hinges.

Custom-made hinges are even more of our strengths, and we have many years of experience in R&D and production. We are currently working on making total structural parts solutions around test equipment. In other words, We not only customize hinges for customers but also customize door handles and other accessories that may be used in conjunction with them.

If these services are what you need now, then contact us now.